Best Home Ice Cube Maker

Top sponsor listing

Top sponsor listing

1/26

1/26

1/25

1/25

1/21

1/21

1/10

1/10

1/21

1/21

1/31

1/31

CN

CN

1/24

1/24

About best home ice cube maker

Where to Find Home Ice Cube Maker Suppliers?

China remains the central hub for home ice cube maker manufacturing, with key production clusters in Guangdong, Shandong, and Henan provinces. Dongguan and Ningbo serve as primary centers for compact, consumer-grade appliances, leveraging localized supply chains for plastic injection molding, refrigeration components, and smart control systems. These regions host vertically integrated facilities capable of full-cycle production—from mold design to final assembly—enabling rapid prototyping and cost-efficient scaling.

The industrial ecosystem supports both low-volume custom orders and high-volume OEM/ODM contracts. Suppliers benefit from proximity to material suppliers and logistics hubs, reducing component lead times by 20–30% compared to offshore alternatives. Average production cycle times range from 15 to 30 days for standard models, with customization adding 7–14 days depending on complexity. Buyers gain access to mature technical networks offering food-grade material compliance, energy-efficient compressor integration, and IoT-enabled controls for next-generation appliances.

How to Choose Home Ice Cube Maker Suppliers?

Effective supplier selection requires a structured evaluation of technical, operational, and transactional performance indicators:

Quality & Compliance Verification

Confirm adherence to international standards including CE, RoHS, and ISO 9001. For household appliances, UL or ETL certification may be required for North American markets. Demand test reports for electrical safety, noise levels (typically ≤45 dB), and daily ice yield consistency under variable ambient temperatures (25–32°C).

Production & Customization Capacity

Assess infrastructure through verifiable metrics:

- Minimum facility size of 2,000m² for dedicated appliance lines

- In-house capabilities in mold design, PCB development, and food-safe material processing (PP, ABS, stainless steel)

- Customization scope covering color, size, logo imprinting, packaging, and user interface labeling

Prioritize suppliers with documented reorder rates below 15%—indicating strong initial product fit—and on-time delivery performance exceeding 95%.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow or letter of credit for first-time transactions. Request physical or digital samples before bulk ordering, verifying ice clarity, freezing cycle time (10–15 minutes per batch), and bin capacity accuracy. Evaluate after-sales support responsiveness, particularly for warranty claims or spare part fulfillment.

What Are the Best Home Ice Cube Maker Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

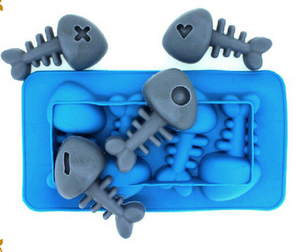

| Dongguan Lucky Goldjyx Company Limited | Cake Tools, Baking & Pastry Tools, Ice Cream Tools, Utensils | 90% | ≤6h | <15% | US $410,000+ | Color, shape, lid, packaging, label, material, size, logo, mold design, 3D drawings, graphic | Custom Manufacturer |

| Shandong Qianrui Machinery Technology Co., Ltd. | Ice Machines, Cold Room Storage, Refrigeration Parts | 100% | ≤1h | <15% | US $9,000+ | Not specified | Unverified |

| Kaifeng Rainbow Machinery Co., Ltd. | Grain & Meat Processing Machines, Food Lines | 95% | ≤2h | <15% | US $10,000+ | Not specified | Unverified |

| Changzhou Aidear Refrigeration Technology Co., Ltd. | Ice Cube Machines, Refrigeration Equipment | 96% | ≤2h | 37% | US $240,000+ | Color, material, size, drawings, logo, packaging, label, graphic, working conditions | Multispecialty Supplier |

| Ningbo TT Smart Technology Co., Ltd. | Electric Ice Makers, Portable & Counter-top Models | 100% | ≤4h | 50% | US $1,000+ | Color, material, size, logo, packaging, label, graphic | Multispecialty Supplier |

Performance Analysis

Dongguan Lucky Goldjyx stands out for extensive customization depth, supporting full design control from mold to labeling, ideal for branded consumer products. Shandong Qianrui demonstrates exceptional reliability with 100% on-time delivery and sub-1-hour response times, though its focus appears skewed toward commercial-scale units. Changzhou Aidear offers strong production volume and refrigeration expertise but exhibits a higher reorder rate (37%), suggesting potential post-sale adjustments. Ningbo TT Smart Technology provides competitive pricing and fast order processing, yet its 50% reorder rate indicates possible quality or service inconsistencies. Suppliers with reorder rates below 15% typically deliver consistent product-market alignment, while faster response times (<2h) correlate with dedicated customer service infrastructure.

FAQs

How to verify home ice cube maker supplier reliability?

Cross-check certifications (CE, RoHS, ISO) with official databases. Request factory audit reports or video tours to confirm in-house production capabilities. Analyze transaction history for on-time delivery consistency and review customer feedback focusing on product durability and technical support.

What is the typical MOQ and pricing range?

MOQ varies: some suppliers offer 1-set trials for countertop models, while others require 200+ units for optimized pricing. Unit costs range from $33 for mini portable units to $1,600 for high-capacity built-in models. Bulk orders (≥500 units) typically achieve 15–25% cost reduction.

Can suppliers customize ice makers for retail branding?

Yes, most suppliers support OEM/ODM services including custom colors, logos, packaging, and user manuals. Full branding projects require 3D design approval and mold development (7–14 days), with minimum order quantities typically starting at 500 units for injection-molded components.

What materials are used in home ice cube makers?

Common materials include food-grade PP or ABS plastics for internal bins, stainless steel for evaporators, and BPA-free components in water pathways. Compressors are typically hermetic rotary or reciprocating types with R134a or R600a refrigerants meeting environmental regulations.

How long does sampling and mass production take?

Sample production takes 7–15 days for standard models; customized units require 14–21 days. Mass production lead time is 20–35 days post-approval, depending on order size and component availability. Air freight delivery adds 5–7 days globally; sea freight requires 25–40 days.