Bfw Double Column Vmc

Top sponsor listing

Top sponsor listing

About bfw double column vmc

Where to Find BFW Double Column VMC Suppliers?

China remains the central hub for ventilation system manufacturing, with key production clusters in Guangdong, Shandong, and Jiangsu provinces driving innovation and scale in double column VMC (Ventilation Mechanical Control) systems. Guangdong’s Pearl River Delta region hosts advanced HVAC manufacturers equipped with automated assembly lines and R&D centers focused on energy recovery and smart ventilation integration. Shandong’s industrial base emphasizes material sourcing efficiency, particularly in HDPE and composite ducting components, reducing raw material costs by 15–20% through localized supply chains.

These regions support vertically integrated operations—from extrusion molding to final system testing—enabling faster turnaround times. Suppliers typically maintain lead times of 20–35 days for standard units, with modular designs allowing for rapid configuration. Buyers benefit from proximity to component suppliers for motors, heat exchangers, and control modules within 50km radii, ensuring streamlined production and after-sales serviceability. The ecosystem supports both high-volume procurement and engineered-to-order solutions tailored to commercial or residential applications.

How to Choose BFW Double Column VMC Suppliers?

Selecting a reliable supplier requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Performance

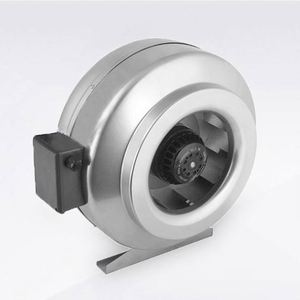

Verify adherence to international standards such as CE, ISO 9001, and RoHS. For double-flux VMC systems, confirm airflow capacity ratings (measured in m³/h), thermal efficiency (>70% for energy recovery models), and noise levels (<45 dB). Request performance test reports for heat exchangers and fan motor endurance under continuous operation cycles.

Production and Customization Capability

Assess core competencies through the following criteria:

- Facility size exceeding 3,000m² indicating scalable output

- In-house design teams capable of customizing airflow dynamics, duct geometry, and control interfaces

- Material processing expertise in HDPE, PP, and insulated sandwich panels for ductwork

Cross-reference online revenue indicators and order fulfillment history with customization claims to validate production flexibility.

Quality Assurance & Transaction Security

Prioritize suppliers demonstrating consistent on-time delivery rates above 95%. Evaluate response time (target ≤4 hours) as an indicator of customer service infrastructure. Use secure payment methods with inspection clauses before shipment. Conduct pre-shipment audits or request factory video tours to verify CNC fabrication lines, sealing integrity tests, and packaging protocols for export durability.

What Are the Best BFW Double Column VMC Suppliers?

| Company Name | Location | Verified Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| E-VIPO TECHNOLOGIES (GUANGDONG) CO., LTD. | Guangdong, CN | Custom Manufacturer | HVAC Systems, Parts | 98% | ≤3h | <15% | US $240,000+ | Color, material, size, logo, packaging, graphic |

| Suzhou MIA Intelligent Technology Co., Ltd. | Jiangsu, CN | - | HVAC Systems, Heat Exchangers, Fans | 100% | ≤4h | <15% | US $10,000+ | No explicit mention |

| Menred Group Yueqing Import And Export Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Energy Recovery Ventilation, Heat Pumps | 100% | ≤2h | 30% | US $280,000+ | Color, material, size, logo, packaging, graphic |

| Hunan Dinghan Environmental Protection Technology Co., Ltd. | Hunan, CN | - | HVAC Systems, Air Filters, Gas Disposal | 100% | ≤1h | <15% | US $10,000+ | No explicit mention |

| Chuangshi Lianxiang New Material Technology(Shandong)Co., Ltd. | Shandong, CN | Custom Manufacturer | Air Ducts, Corrugated Pipes, Brackets | 93% | ≤9h | <15% | US $9,000+ | No explicit mention |

Performance Analysis

Suzhou MIA and Hunan Dinghan achieve perfect on-time delivery records, suggesting robust production planning and inventory control. Menred Group stands out with a 30% reorder rate and sub-2-hour response time, reflecting strong post-sale satisfaction and operational responsiveness. E-VIPO leads in digital sales volume (US $240,000+), indicating established market presence and export experience. Suppliers offering full customization—such as E-VIPO and Menred—are better suited for OEM or project-specific deployments requiring branding or dimensional adjustments. Buyers seeking complete VMC units should prioritize companies listing heat exchangers, fans, and control systems as main products, while those needing ducting components may leverage Shandong-based material specialists.

FAQs

How to verify BFW double column VMC supplier reliability?

Cross-check certifications with issuing bodies and request product test reports for airflow efficiency, pressure drop, and sound levels. Analyze historical order data, including repeat purchase rates and dispute resolution outcomes. Video audits of production floors and quality checkpoints add verification depth.

What is the typical MOQ and pricing range?

Minimum Order Quantities vary: single units are available from US $256 for compact models, while bulk orders start at 50–100 sets or meters depending on component type. Pricing ranges from $0.50/meter for corrugated ducting to over $3,000 for large-capacity energy recovery units.

Do suppliers offer customization for BFW VMC systems?

Yes, select manufacturers provide full customization including color, material grade, unit dimensions, control panel layout, and branding elements like logos and packaging design. Confirm tooling lead times (typically 10–15 days) and NRE fees for non-standard configurations.

What are standard lead times for production and shipping?

Production lead time averages 20–30 days for standard units and 35–45 days for customized systems. Air freight delivery takes 5–10 days internationally; sea freight requires 25–35 days depending on destination port.

Can suppliers handle global logistics and compliance?

Experienced exporters manage FOB and CIF shipments with documentation for customs clearance. Confirm compliance with regional electrical safety (e.g., CE, UL) and building code requirements prior to order placement, especially for integrated fan-motor assemblies.