Big Round Ice Cube Maker

1/23

1/23

1/9

1/9

1/29

1/29

1/25

1/25

1/21

1/21

1/12

1/12

About big round ice cube maker

Where to Find Big Round Ice Cube Maker Suppliers?

China remains the central hub for manufacturing big round ice cube makers, with key production clusters concentrated in Guangdong Province—particularly Shenzhen and Foshan. These regions host vertically integrated supply chains specializing in silicone molding, plastic injection, and kitchenware assembly, enabling rapid prototyping and scalable production. Shenzhen’s ecosystem excels in consumer-grade silicone products, supported by advanced material testing labs and logistics networks that facilitate global distribution within 15–25 days via air or sea freight.

The industrial advantage lies in localized access to raw materials such as food-grade platinum-cured silicone and BPA-free polypropylene, reducing material lead times by up to 40%. Manufacturers benefit from co-located mold-making workshops and packaging facilities, allowing for end-to-end control over production cycles. This integration supports MOQs as low as 20 pieces for standard molds and enables cost efficiencies of 20–30% compared to equivalent suppliers outside Asia. Buyers gain flexibility in volume scaling, with monthly output capacities ranging from 50,000 to over 200,000 units per facility.

How to Choose Big Round Ice Cube Maker Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Material & Safety Compliance

Confirm use of food-contact compliant materials (FDA 21 CFR §177.2600 or EU Regulation 10/2011). Suppliers should provide test reports verifying absence of BPA, phthalates, and heavy metals. For electric models, ensure compliance with IEC 60335 safety standards and CE/ROHS certification where applicable.

Production Capability Assessment

Evaluate core manufacturing competencies:

- In-house mold design and CNC tooling capabilities for custom shapes

- Monthly production capacity exceeding 50,000 units for volume orders

- Use of multi-cavity silicone compression molding for consistent cavity geometry

Cross-reference on-time delivery rates (target ≥96%) and response time metrics (≤5 hours) as indicators of operational reliability.

Customization & Transaction Security

Prioritize suppliers offering Pantone color matching, logo embossing, and packaging customization. Verify participation in verified trade programs to enable escrow-based payments. Request physical samples before bulk ordering to assess wall thickness uniformity, demolding ease, and dimensional accuracy of spherical cavities (typically 6.5 cm diameter).

What Are the Best Big Round Ice Cube Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Baibanfengxing Technology Co., Ltd. | Shenzhen, CN | Fruit & Vegetable Tools, Stainless Steel Tumblers, Ice Cream Tools | US $280,000+ | 97% | ≤5h | <15% | 20–50 pcs | $0.39–$0.79 |

| Shenzhen Zhongguanyi Technology Co.,Ltd. | Shenzhen, CN | Ice Cream Tools, Baking Pads, Pastry Molds | US $30,000+ | 96% | ≤2h | 25% | 20–1,000 pcs | $0.52–$2.50 |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Shenzhen, CN | Silicone Molds, Reusable Ice Makers (Customizable) | US $250,000+ | 93% | ≤3h | <15% | 10–100 pcs | $0.62–$19.31 |

| Yiwu JYH E-commerce Co., Ltd. | Yiwu, CN | Wholesale Silicone Molds, Whiskey Accessories | US $70,000+ | 100% | ≤3h | 18% | 50–200 pcs | $0.56–$3.94 |

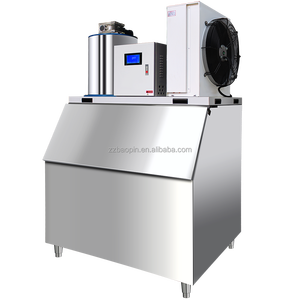

| Foshan Diaking Industry Co., Ltd. | Foshan, CN | Electric Countertop Ice Makers, Industrial Machines | US $100+ | 100% | ≤4h | <15% | 2–300 pcs | $128–$600 |

Performance Analysis

Shenzhen-based suppliers dominate in product variety and responsiveness, with two achieving sub-3-hour average reply times. Shenzhen Baibanfengxing offers the lowest entry pricing ($0.39/unit), ideal for budget-conscious buyers seeking basic silicone molds. Shenzhen Benhaida stands out for customization depth, supporting full design modifications including shape, color, and labeling—critical for branded retail lines. Yiwu JYH demonstrates perfect on-time delivery performance, a key metric for time-sensitive campaigns. Foshan Diaking is the sole provider of motorized countertop units capable of producing large spherical ice without manual filling, though at significantly higher MOQs and unit costs. Suppliers with online revenues exceeding US $250,000 show sustained market presence and diversified client bases, suggesting stronger quality consistency and post-sale support infrastructure.

FAQs

How to verify big round ice cube maker material safety?

Request compliance documentation for FDA, LFGB, or EU 10/2011 standards. Conduct third-party lab testing for extractables and volatility if intended for commercial foodservice use. Visually inspect sample units for homogeneity and odorless composition after freezing cycles.

What is the typical lead time for bulk orders?

Standard silicone molds require 12–18 days for production after confirmation. Custom tooling adds 7–10 days. Electric models may take 25–35 days due to electronic component sourcing. Air freight adds 5–7 days; sea freight ranges from 18–30 days depending on destination port.

Can suppliers produce custom-shaped ice molds?

Yes, manufacturers with in-house mold engineering—such as Shenzhen Benhaida—support custom cavity designs, including polygonal spheres, logo-imprinted cubes, and oversized formats (up to 8 cm diameter). Minimum tooling investment starts at $150 for simple modifications.

Do suppliers offer free samples?

Most suppliers provide paid samples ($5–$20) deductible from first orders. Free samples are typically reserved for buyers committing to MOQs above 500 units. Expect 3–7 days for sample dispatch after payment clearance.

What packaging options are available for retail readiness?

Common options include blister cards, gift boxes, and polybags with hang tags. Full retail packaging customization—including branding, multilingual inserts, and EAN barcode integration—is offered by suppliers with dedicated packaging lines, often requiring minimum runs of 1,000 units.