Bopp Labeling Machine

1/15

1/15

1/20

1/20

1/12

1/12

1/23

1/23

1/22

1/22

1/25

1/25

1/25

1/25

About bopp labeling machine

Where to Find BOPP Labeling Machine Suppliers?

China remains the central hub for BOPP labeling machine manufacturing, with key production clusters in Jiangsu, Shanghai, and Henan provinces. These regions host vertically integrated supply chains combining precision engineering, packaging automation expertise, and access to raw materials like polypropylene films and hot-melt adhesives. Zhangjiagang and Shanghai specialize in high-speed rotary labeling systems capable of processing 12,000–18,000 bottles per hour, serving beverage, pharmaceutical, and chemical industries. Henan’s industrial base focuses on compact desktop and semi-automatic models ideal for small-to-medium enterprises requiring flexible batch processing.

The geographic concentration enables efficient component sourcing—servo motors, PLC controls, and pneumatic systems are available within 50km of major factories—reducing lead times by up to 30%. Buyers benefit from scalable production networks where customization does not significantly impact delivery schedules. Standard lead times range from 20–40 days depending on automation level, with localized logistics minimizing export delays. The ecosystem supports both mass production (MOQs as low as 1 set) and OEM/ODM configurations across label types including roll-fed, wrap-around, and self-adhesive BOPP applications.

How to Choose BOPP Labeling Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

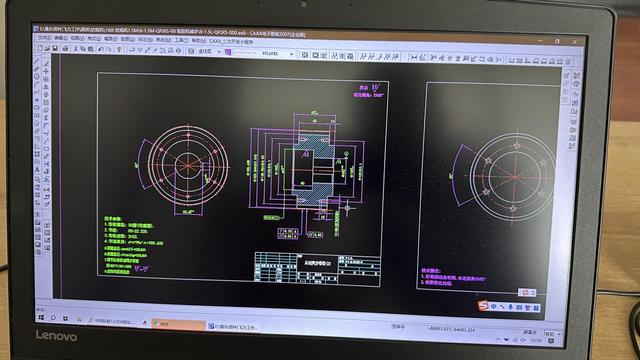

Verify that suppliers design machines compatible with BOPP film thicknesses (20–50μm) and common adhesive systems (hot-melt or solvent-based). Look for integration readiness with upstream filling or downstream capping lines. For international markets, CE marking is essential for regulatory compliance, particularly in Europe. Although not explicitly stated in all profiles, suppliers with robust R&D capabilities typically maintain ISO 9001-certified quality management systems.

Production Capacity and Scalability

Assess infrastructure indicators such as factory size, output volume, and engineering team strength. High-performance rotary labeling machines require CNC machining centers, laser alignment tools, and vibration testing rigs. Prioritize suppliers offering:

- Minimum monthly output capacity exceeding 30 units

- In-house control panel assembly and software programming

- Customization options for bottle shape, diameter, and label positioning accuracy (±0.5mm tolerance)

Cross-reference online revenue metrics and reorder rates as proxies for production stability and customer satisfaction.

Transaction Security and After-Sales Support

Use secure payment mechanisms such as escrow services to mitigate risk. Evaluate responsiveness (target ≤5 hours) and historical on-time delivery performance—suppliers reporting ≥98% fulfillment rates demonstrate logistical reliability. Confirm availability of remote diagnostics, operator training, and spare parts inventory. Request sample units to validate labeling consistency, glue application uniformity, and material handling durability before full-scale procurement.

What Are the Best BOPP Labeling Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang Sunswell Machinery Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $2,500,000+ | 100.0% | ≤5h | 100% | Rotary, linear, roll-feed | $24,300–$100,000 |

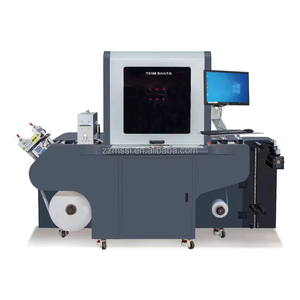

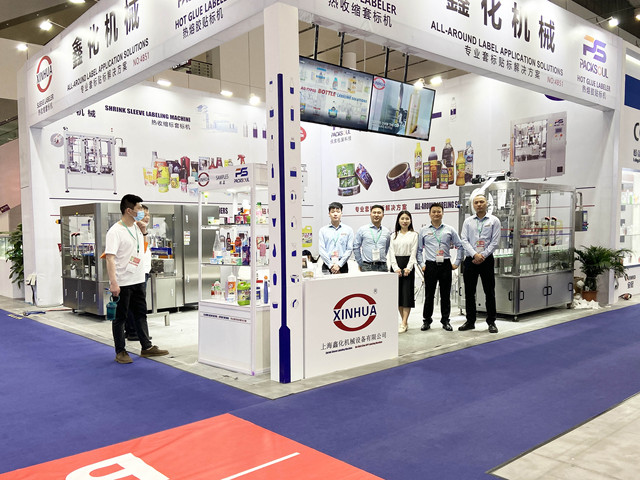

| Shanghai Xinhua Machinery Equipment Co., Ltd. | Shanghai, CN | — | US $390,000+ | 100.0% | ≤4h | <15% | Bottle, water, carbonated | $30,000–$70,000 |

| Zhangjiagang Merck Machinery Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $350,000+ | 100.0% | ≤5h | 42% | Linear, rotary, hot-melt | $5,000–$9,900 |

| Foshan Land Packaging Machinery Co., Ltd. | Guangdong, CN | — | US $660,000+ | 93.0% | ≤3h | 25% | Multi-functional lines | $7,874–$10,500 |

| Henan Bayern Industrial Co., Ltd. | Henan, CN | Multispecialty Supplier | US $290,000+ | 98.0% | ≤1h | 21% | Desktop, pouch, jar | $1,350–$1,500 |

Performance Analysis

Zhangjiagang Sunswell stands out with a 100% reorder rate and multi-million-dollar annual online revenue, indicating strong market trust and repeat business—key markers of product reliability and service quality. Its mid-to-high price range reflects investment in advanced rotary systems designed for large-scale beverage and chemical packaging. In contrast, Henan Bayern offers entry-level desktop models at highly competitive prices ($1,350/set), catering to startups or niche producers needing basic labeling functionality for pouches and jars.

Shanghai Xinhua targets premium industrial clients with high-capacity machines priced above $30,000, though its sub-15% reorder rate suggests room for improvement in post-sale engagement. Foshan Land provides integrated packaging line solutions, enhancing value through multi-machine synchronization. While its on-time delivery rate is slightly lower (93%), its broad product scope supports complex production environments. Buyers seeking rapid response times should consider Henan Bayern, which guarantees replies within one hour—an advantage for urgent sourcing cycles.

FAQs

How to verify BOPP labeling machine supplier reliability?

Validate technical credentials through facility videos showing CNC workshops and testing lines. Check for consistent product listings with detailed specifications (label speed, film compatibility, power consumption). Analyze transaction data: on-time delivery ≥98%, response time ≤5h, and reorder rates >20% indicate operational maturity. Request third-party inspection reports if available.

What is the average lead time for BOPP labeling machines?

Standard models ship within 20–30 days after order confirmation. Customized or high-speed rotary systems may require 35–45 days due to mechanical calibration and control system programming. Express manufacturing options exist but incur additional costs.

Can suppliers customize BOPP labeling machines?

Yes, most manufacturers offer OEM/ODM services including logo printing, voltage adjustment (220V/380V), language-specific HMI interfaces, and modifications for non-standard container shapes. Full customization—from mold design to sensor integration—is available from verified custom manufacturers like Zhangjiagang Sunswell and Merck Machinery.

Do BOPP labeling machines support different film types?

High-end models accommodate various BOPP formats including pre-cut labels, roll-fed films, and heat-activated adhesives. Ensure compatibility with your specific film width (typically 50–150mm) and thickness. Some machines also handle OPP, PET, and laminated films with minor adjustments.

Are samples available before bulk ordering?

Sample units are generally available upon request, often at full price or partially subsidized based on projected order volume. Testing samples allows verification of labeling accuracy, glue distribution, and integration with existing conveyors. Allocate 7–14 days for sample dispatch and another 5–10 days for international delivery via express freight.