Labeling Machinery

Top sponsor listing

Top sponsor listing

1/13

1/13

1/14

1/14

1/20

1/20

1/22

1/22

1/13

1/13

1/20

1/20

1/12

1/12

1/3

1/3

1/15

1/15

1/8

1/8

1/25

1/25

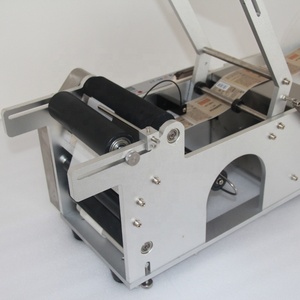

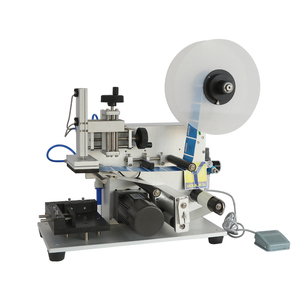

About labeling machinery

Where to Find Labeling Machinery Suppliers?

China remains the global epicenter for labeling machinery production, with key manufacturing clusters concentrated in Guangdong and Zhejiang provinces. Guangdong, particularly around Guangzhou and Foshan, hosts integrated packaging equipment ecosystems supported by advanced automation R&D centers and high-capacity component suppliers. Zhejiang’s Wenzhou and Hangzhou regions specialize in precision labeling systems, leveraging localized stainless steel fabrication and sensor integration capabilities that reduce material lead times by 20–25% compared to offshore alternatives.

These industrial hubs offer vertically aligned supply chains—encompassing CNC machining, servo motor assembly, and touch-control panel manufacturing—within a 50-kilometer radius. This proximity enables rapid prototyping, batch scalability, and reduced logistics overhead. Buyers benefit from average production lead times of 25–40 days for standard models, with cost advantages of 18–30% over European or North American manufacturers due to lower labor and material procurement costs. The region also supports flexible MOQs, ranging from single-unit desktop applicators to full-line automated systems for large-scale operations.

How to Choose Labeling Machinery Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international quality standards such as ISO 9001. For export markets, CE certification is essential for regulatory compliance in Europe, while UL or CSA markings may be required for North America. Request documentation on electrical safety, labeling accuracy testing, and material traceability—particularly for food-grade or pharmaceutical applications where stainless steel (SUS304/SUS316) construction is mandatory.

Production & Technical Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for sustained volume output

- In-house engineering teams capable of custom fixture design (e.g., bottle shape adaptability, label roll tension control)

- On-site CNC, welding, and sensor calibration facilities

Cross-reference delivery performance (target ≥97%) with response time (≤2 hours preferred) to assess operational responsiveness and order prioritization.

Transaction & Risk Mitigation Protocols

Utilize secure payment mechanisms such as escrow services to align payment milestones with shipment and inspection phases. Prioritize suppliers with documented after-sales support, including remote diagnostics and spare parts availability. Conduct sample validation to verify labeling speed (measured in units per minute), positional accuracy (±0.5mm tolerance), and compatibility with substrate materials (plastic, glass, metal, or composite).

What Are the Best Labeling Machinery Suppliers?

| Company Name | Location | Type | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Guangdong Feibin Machinery Group Co., Ltd. | Guangdong, CN | Custom Manufacturer | Labeling Machines, Filling Machines, Multi-Function Packaging Systems | 98% | ≤2h | US $1.7M+ | 24% | Yes (machine type, size, sensor, direction, logo) |

| Wenzhou Haizhou Import And Export Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Semi-Auto & Automatic Labelers, Desktop Applicators | 99% | ≤1h | US $960K+ | <15% | Yes (bottle diameter, label size, coding, power) |

| Jining Keepway Machinery Company Ltd. | Shandong, CN | Multispecialty Supplier | Round Bottle, Flat Surface, Jar Labeling Machines | 97% | ≤2h | US $610K+ | 36% | Limited |

| Wenzhou Aimesk Intelligent Equipment Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | Semi-Automatic & Automatic Labeling Systems | 99% | ≤2h | US $320K+ | <15% | Yes (material, color, size, graphic layout) |

| Hefei Minssine Packaging Technology Co., Ltd. | Anhui, CN | Multispecialty Supplier | Semi-Automatic Round Bottle Labelers | 100% | ≤3h | US $30K+ | <15% | Limited |

Performance Analysis

Guangdong Feibin and Wenzhou Haizhou stand out as leading custom manufacturers with robust production infrastructure, extensive product ranges, and strong revenue performance. Haizhou demonstrates superior responsiveness (≤1h) and high on-time delivery (99%), making it ideal for urgent or iterative procurement cycles. Jining Keepway exhibits the highest reorder rate (36%), indicating strong customer satisfaction despite limited customization offerings. Hefei Minssine achieves perfect on-time delivery but operates at a smaller scale, suitable for low-volume buyers seeking reliability over scalability. Suppliers in Zhejiang province lead in customization depth, offering adjustments in labeling direction, sensor configuration, and coding integration—critical for specialized packaging workflows.

FAQs

How to verify labeling machinery supplier reliability?

Validate certifications (ISO 9001, CE) through official registries. Request facility audit reports or video tours confirming in-house production lines and quality control stations. Analyze buyer feedback focusing on post-delivery support, machine durability, and accuracy consistency under continuous operation.

What is the typical MOQ and lead time?

MOQs range from 1 unit for desktop models to 5+ sets for automated lines. Standard lead times are 20–35 days post-deposit, with expedited builds possible in 15 days for semi-automatic units. Custom configurations may extend timelines by 10–15 days.

Can suppliers accommodate custom labeling requirements?

Yes, select manufacturers offer tailored solutions for bottle shape, label dimensions, conveyor integration, and print synchronization. Provide technical drawings or samples to enable precise fixture and sensor alignment. Lead time for prototypes: 7–14 days.

Do labeling machines support multiple container types?

Advanced models handle round bottles, flat surfaces, oval containers, and tapered jars via adjustable guides and programmable logic controllers (PLC). Confirm compatibility with your primary substrates—glass, PET, HDPE, or metal—and labeling method (wrap, front/back, top-surface).

What are common power and operational specifications?

Standard units operate on 110V/220V, 50/60Hz, with power consumption between 300W–1.5kW depending on automation level. Pneumatic models require 0.4–0.6 MPa air pressure. Ensure facility compatibility before deployment.