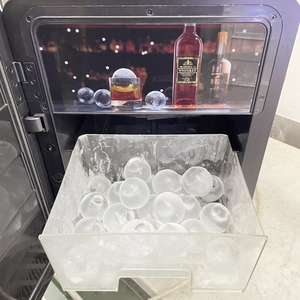

Built In Clear Ice Maker

CN

CN

About built in clear ice maker

Where to Find Built-in Clear Ice Maker Suppliers?

China remains the global manufacturing hub for commercial and industrial ice-making equipment, with key supplier clusters in Zhejiang, Guangdong, and Henan provinces. These regions host vertically integrated production ecosystems specializing in refrigeration technology, enabling efficient sourcing of built-in clear ice makers. Zhejiang’s Ningbo and Cixi areas are renowned for compact under-counter units used in hospitality and retail, while Guangdong's Guangzhou-based manufacturers focus on high-capacity systems for food service chains and industrial applications. Henan and Shandong contribute to large-scale block and tube ice solutions, leveraging localized stainless steel and compressor supply networks.

The concentration of component suppliers—compressors, evaporators, condensers, and control panels—within 50–100 km radii reduces lead times and logistics costs by up to 25%. Most facilities operate automated assembly lines with semi-automated welding and precision CNC machining for housings, ensuring dimensional consistency. Monthly production capacities range from 500 to over 5,000 units depending on factory scale, supporting both bulk procurement and custom configurations. Buyers benefit from short development cycles (typically 7–14 days for prototype validation) and flexible MOQs starting at one unit for select models.

How to Choose Built-in Clear Ice Maker Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capabilities

Verify adherence to international electrical and safety standards such as CE, RoHS, and UL where applicable. For commercial deployments, confirm that cooling systems utilize R134a or R404A refrigerants compliant with environmental regulations. Evaluate design features including air-cooled vs. water-cooled condensers, drain pump integration, and anti-corrosion treatments on stainless steel components (typically SUS304 grade). Prioritize suppliers offering CAD drawings, performance specifications (ice production rate, power consumption, noise levels), and third-party test reports.

Production Infrastructure Assessment

Key indicators of manufacturing maturity include:

- Minimum facility size of 2,000m² for dedicated refrigeration production lines

- In-house capabilities in sheet metal fabrication, foam insulation injection, and hermetic sealing

- Presence of environmental simulation chambers for cycle testing under variable ambient conditions

Cross-reference declared output volumes with verified online revenue data and reorder rates to assess scalability and market acceptance.

Quality Assurance & Transaction Security

Demand documented quality control processes including incoming material inspection (IMI), in-process checks, and final product testing (FPT). On-time delivery rates exceeding 95% and response times under 8 hours indicate operational reliability. Utilize secure payment mechanisms such as escrow services and insist on pre-shipment inspections (PSI) via third-party agencies like SGS or Bureau Veritas. Sample validation is critical—test ice clarity, cycle duration, and energy efficiency before placing volume orders.

What Are the Best Built-in Clear Ice Maker Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Wellcooling Intelligent Technology (JM) Co., Ltd. | Ice Machines (127), Ice Cream Machines (371) | US $140,000+ | 100% | ≤9h | 16% | 1 unit | $300–$1,488 |

| Cixi Jirui Electric Appliance Co., Ltd. | Ice Makers (135), Ice Crushers (195) | US $2,000+ | 50% | ≤7h | <15% | 2–10 pieces | $230–$620 |

| Shangqiu Bingya Refrigeration Equipment Co., Ltd. | Ice Machines (663), Popsicle Machines (666) | US $30,000+ | 100% | ≤2h | <15% | 1 piece/set | $899–$4,999 |

| Guangzhou Hefforts Refrigeration Equipment Co., Ltd. | Ice Machines (207), Ice Makers (53) | — | 100% | ≤16h | — | 1–2 sets | $1,000–$25,000 |

| Whalfly Tek Co., Ltd. | Ice Makers (470), Ice Cream Makers (84) | US $9,000+ | 100% | ≤1h | <15% | 1 unit/piece | $39.90–$159.99 |

Performance Analysis

Wellcooling and Whalfly Tek stand out for low MOQs and rapid engagement, making them suitable for SMEs and cross-border e-commerce buyers. Whalfly offers the lowest entry price point ($39.90) for small countertop units producing clear bullet or sphere ice, though its product scope is limited to niche designs. Wellcooling provides broader application coverage—from freestanding to built-in models—with strong fulfillment reliability (100% on-time delivery). Shangqiu Bingya targets premium commercial clients with high-output transparent cube and block ice systems priced above $900, backed by robust technical infrastructure. Guangzhou Hefforts specializes in large tonnage installations (up to 5 tons/day), ideal for industrial processing plants requiring customized engineering. Cixi Jirui presents competitive pricing but shows lower delivery consistency (50%), indicating potential fulfillment risks despite responsive communication.

FAQs

How to verify built-in clear ice maker supplier reliability?

Validate certifications through official databases and request factory audit reports or video walkthroughs of production lines. Analyze customer feedback focusing on after-sales service, spare parts availability, and long-term durability. Confirm warranty terms (typically 12–24 months) and technical support responsiveness.

What is the typical lead time for sample and bulk orders?

Sample units ship within 7–15 days after confirmation. Bulk order lead times vary: 20–30 days for standard models, 35–50 days for customized units requiring modified molds or control systems. Air freight delivers samples in 5–10 days globally; sea freight takes 25–40 days depending on destination port.

Can suppliers accommodate OEM/ODM requests?

Yes, most suppliers listed offer OEM branding, custom color finishes, voltage adjustments (110V/220V/380V), and control panel localization. Minimum order thresholds for customization typically start at 50–100 units, with NRE fees waived for larger contracts.

Do built-in clear ice makers require special installation conditions?

Under-counter models require proper ventilation clearance (minimum 10 cm rear/side gaps), proximity to drainage points, and stable power supply. Air-cooled units perform optimally below 32°C ambient temperature. Ensure compliance with local plumbing and electrical codes during integration.

What factors influence ice clarity in built-in ice makers?

Clear ice formation depends on directional freezing technology, purified water feed, and slow freeze cycles that expel impurities. High-end models use circulating pumps and insulated molds to achieve optical clarity. Avoid hard water sources and maintain regular descaling schedules to preserve clarity and machine longevity.