Button Maker Punch

1/25

1/25

1/15

1/15

1/33

1/33

1/9

1/9

1/24

1/24

1/15

1/15

1/12

1/12

About button maker punch

Where to Find Button Maker Punch Suppliers?

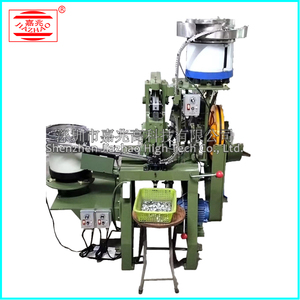

China remains the global epicenter for button maker punch production, with concentrated manufacturing hubs in Guangzhou and Yiwu offering specialized expertise in small-format badge and apparel machinery. These regions host vertically integrated supply chains capable of producing manual, semi-automatic, and fully automatic systems across a range of diameters (10mm–58mm), serving both craft and industrial applications.

The industrial clusters benefit from mature ecosystems combining precision tooling, die-casting, and mechanical assembly under one roof. This integration enables rapid prototyping and scalable production, with lead times averaging 7–15 days for standard models. Localized access to raw materials such as zinc alloy dies, steel punches, and plastic molds reduces component costs by 20–30% compared to non-specialized manufacturers. Buyers gain flexibility in order volume—from single-piece samples to container-scale shipments—supported by responsive logistics networks connecting to major export ports like Ningbo and Shenzhen.

How to Choose Button Maker Punch Suppliers?

Effective supplier selection requires structured evaluation across three core dimensions:

Technical Capability Verification

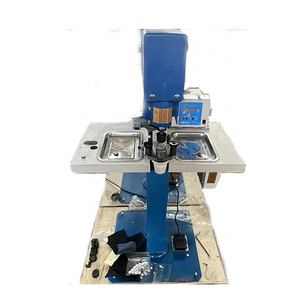

Confirm compatibility with required button sizes (e.g., 25mm, 37mm, 58mm) and material types (metal, plastic). For industrial buyers, assess machine actuation type: manual lever, pneumatic, or electric servo systems. High-volume operations should prioritize suppliers offering semi-automatic or automatic lines with cycle speeds exceeding 60 units per minute. Request technical drawings and operational videos to validate build quality and mechanism efficiency.

Production & Quality Assurance Metrics

Evaluate suppliers using verifiable performance indicators:

- On-time delivery rate ≥90% indicates reliable logistics management

- Reorder rates above 20% reflect customer satisfaction and product reliability

- Response time ≤4 hours ensures timely communication for issue resolution

- Minimum online transaction volume (e.g., US $30,000+) suggests market validation

Cross-reference these metrics with product listings to identify consistent performers. Suppliers investing in R&D typically offer innovations such as installation-free assembly or multi-diameter adaptability.

Procurement Risk Mitigation

Utilize secure payment methods with milestone-based disbursement. Prioritize suppliers with documented quality control processes, including pre-shipment inspection protocols. Request physical or digital samples to evaluate punch durability, alignment accuracy, and ease of operation. For custom configurations—such as branded dies or dual-station setups—confirm engineering support and tooling modification lead times (typically 5–10 days).

What Are the Best Button Maker Punch Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| GED (Guangzhou) Import And Export Limited | Guangzhou, CN | Button Making Machines, Heat Press, Printing Machinery | $23–38 | 1 piece | 100% | ≤8h | <15% | US $60,000+ |

| Yiwu Chuxin Technology Co., Ltd | Yiwu, CN | Button Making Machines, Badge Holders, Apparel Parts | $15–39 | 1 piece | 85% | ≤2h | 20% | US $10,000+ |

| Yiwu Wantu Machinery Equipment Co., Ltd. | Yiwu, CN | Button Making Machines, Metal Crafts, Promotional Items | $45–260 | 1 set/pack | 100% | ≤3h | 16% | US $30,000+ |

| Maanshan Wila CNC Machine Tools Co., Ltd. | Maanshan, CN | Automatic Punch Press, Eyelet Machines, CNC Tools | $3,800–6,100 | 1 piece/set | 90% | ≤4h | 33% | US $20,000+ |

| Hangzhou Qike Technology Co., Ltd. | Hangzhou, CN | Sewing Machines, Automatic Button Hole Equipment | $165–1,980 | 1 set | 100% | ≤2h | 18% | US $410,000+ |

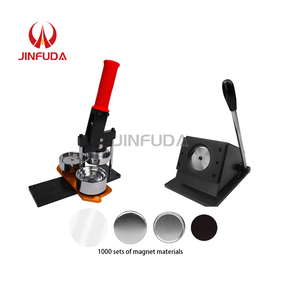

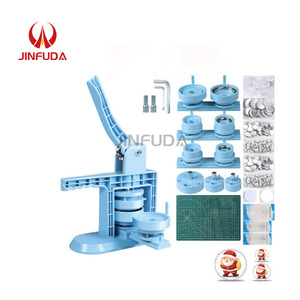

Performance Analysis

GED (Guangzhou) stands out for entry-level manual machines with competitive pricing ($23–25) and perfect on-time delivery, though its low reorder rate suggests limited post-sale engagement. Yiwu Chuxin offers the lowest price point at $15 for 58mm button makers, backed by fast response times, making it suitable for budget-conscious buyers prioritizing communication speed. Yiwu Wantu provides higher-end manual and pneumatic models, with a strong 100% delivery record and mid-range pricing ideal for small business procurement.

For industrial automation, Maanshan Wila and Hangzhou Qike represent premium-tier suppliers. Maanshan Wila specializes in high-tonnage automatic punch presses priced between $3,800 and $6,100, targeting metal component manufacturers requiring precision and throughput. Hangzhou Qike delivers integrated apparel machinery solutions, including automated button hole sewing systems, supported by substantial online revenue (over US $410,000) and full delivery reliability. Its product line bridges button making with broader garment processing workflows.

FAQs

What is the typical MOQ for button maker punch machines?

Most suppliers offer a minimum order quantity of 1 piece for standard manual models, enabling sample testing and small business adoption. Automated systems are typically sold in sets with MOQs of 1 unit due to complexity and packaging requirements.

How long does production and shipping take?

Standard orders are processed within 7–15 days after confirmation. Air freight delivery to North America or Europe takes 5–10 days; sea freight requires 25–35 days. Customized machines may add 5–10 days for tooling adjustments.

Are certifications available for export compliance?

While not universally declared, suppliers with established export histories often comply with CE standards upon request. Buyers should explicitly confirm certification availability for customs clearance in regulated markets.

Can I customize punch diameter or design?

Yes, many suppliers support customization of punch size, handle configuration, and die engraving. Semi-automatic and automatic models can be adapted for specific press force or feed mechanisms. Prototype development typically takes 7–14 days following technical specification submission.

Do suppliers provide after-sales support?

Support varies by supplier. Top-tier vendors offer operational guidance, spare parts supply, and troubleshooting via digital channels. For automated systems, some provide remote diagnostics or maintenance manuals. Confirm service terms prior to purchase.