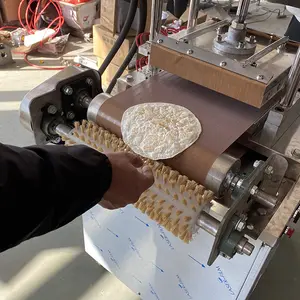

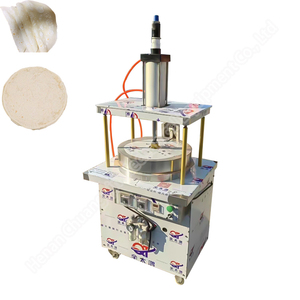

Chappal Making Machine Fully Automatic

0

0

0

0

0

0

1/18

1/18

1/12

1/12

0

0

1/3

1/3

1/11

1/11

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/21

1/21

1/1

1/1

1/2

1/2

1/3

1/3

0

0

1/3

1/3

About chappal making machine fully automatic

Where to Find Chappal Making Machine Suppliers?

China remains the central hub for fully automatic chappal making machine production, with key manufacturing clusters in Henan and surrounding regions. These industrial zones benefit from concentrated supply chains for food processing machinery components, enabling cost-efficient fabrication of automated flatbread systems. Suppliers in Zhengzhou and Qixian leverage regional infrastructure to streamline logistics, reducing export lead times by up to 25% compared to non-specialized regions.

The ecosystem supports both compact tabletop units and large-scale commercial systems, with manufacturers offering vertically integrated production from sheet metal forming to final assembly. This integration allows rapid prototyping and scalability, particularly for high-volume orders. Buyers gain access to facilities equipped with CNC machining, welding automation, and stainless steel polishing lines—critical for hygienic food contact surfaces. Average delivery windows range from 15–30 days for standard models, with localized sourcing cutting material costs by 18–22% versus international alternatives.

How to Choose Chappal Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify that machines meet functional requirements: dough feeding precision, baking temperature control (typically 200–300°C), cycle time (3–6 seconds per unit), and compatibility with multiple flour types. While formal certifications (ISO, CE) are not universally listed, prioritize suppliers who provide test reports on motor efficiency, thermal stability, and electrical safety standards. Stainless steel construction (grade 304 or equivalent) should be standard for corrosion resistance and food-grade compliance.

Production Capacity Verification

Assess manufacturing scale through observable indicators:

- Facility size inferred from product range and listing volume

- In-house R&D capability indicated by customization options (size, power, crust control)

- Processing techniques including laser cutting, press forming, and automated conveyor integration

Cross-reference response times (≤1 hour preferred) and on-time delivery records where available to gauge operational reliability.

Procurement Risk Mitigation

Utilize secure payment terms such as escrow services until post-delivery inspection is completed. Request sample units to validate performance under real operating conditions—particularly critical for texture consistency and throughput accuracy. Confirm packaging standards (wooden crates for export) and inclusion of user manuals, spare parts kits, and voltage compatibility documentation.

What Are the Best Chappal Making Machine Suppliers?

| Company Name | Main Products (Listings) | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Qixian Xincheng E-Commerce Co., Ltd. | Grain Product Making Machines (1,346) | $323.40–346.50 | 1 dozen | 100% | ≤1h | <15% | US $2,000+ | Not specified |

| YANN TECHNOLOGY LLC | Grain Product Making Machines (2,269) | $650–8,000 | 1 set | Not reported | ≤1h | Not reported | Not reported | Not specified |

| Yongtao Group (Henan) Co., Ltd. | Grain Product Making Machines (174) | $450–750 | 1 piece | Not reported | ≤4h | Not reported | Not reported | Not specified |

| SSS Hardware International Trading Co., Ltd. | Customization-focused supplier | $4,050–10,500 | 1 set | 100% | ≤4h | <15% | US $800+ | Color, shape, size, power, logo, packaging, material, fermentation, crust diameter |

| Zhengzhou Canmax Machinery&equipment Co., Ltd. | Integrated food machinery systems | $699–11,000 | 1 set | 100% | ≤4h | 37% | US $330,000+ | Color, material, shape, size, logo, packaging, documents, graphic |

Performance Analysis

Qixian Xincheng stands out for entry-level procurement with competitive pricing and verified on-time delivery, though limited to smaller batch orders (per dozen). YANN TECHNOLOGY offers a broad mid-range portfolio, suitable for buyers seeking scalable solutions across different output capacities. Yongtao Group provides accessible pricing but lacks performance metrics, increasing due diligence requirements. SSS Hardware distinguishes itself through extensive customization depth, ideal for branded or region-specific deployments. Zhengzhou Canmax leads in customer retention (37% reorder rate) and revenue volume, indicating strong post-sale satisfaction and export experience—making it optimal for large institutional or franchise deployments requiring uniformity and support.

FAQs

How to verify chappal making machine supplier reliability?

Validate operational history, response consistency, and delivery performance. Request factory videos or virtual audits to confirm production lines. Analyze customer feedback focusing on after-sales service, defect rates, and technical support responsiveness.

What is the typical sampling timeline?

Standard samples ship within 7–14 days. Custom configurations may require 20–30 days depending on mechanical modifications. Air freight adds 5–10 days for international delivery.

Can suppliers ship globally?

Yes, most suppliers support worldwide shipping via air or sea freight. Confirm Incoterms (FOB/CIF), customs documentation, and voltage adaptation (e.g., 220V/50Hz vs. 110V/60Hz) prior to order placement.

Do suppliers offer free samples?

Free samples are uncommon. Sample fees typically apply but may be credited toward bulk orders. Expect costs covering 30–50% of unit price for testing purposes.

How to initiate customization requests?

Submit detailed specifications: desired output capacity (units/hour), input voltage, footprint constraints, dough thickness range, and branding elements. Leading suppliers respond with engineering drawings or 3D models within 72 hours for approval prior to production.