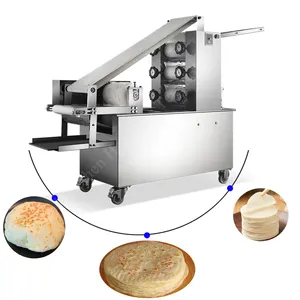

Fully Automatic Chapati Making Machine

About fully automatic chapati making machine

Where to Find Fully Automatic Chapati Making Machine Suppliers?

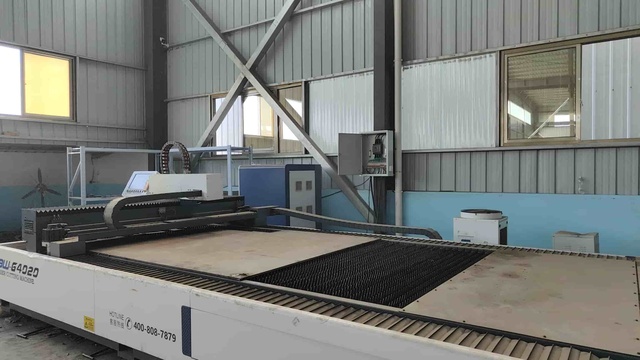

China remains the global epicenter for fully automatic chapati making machine manufacturing, with key production clusters concentrated in Henan province. This region hosts a high density of food processing equipment manufacturers leveraging integrated supply chains for motors, molds, and stainless steel components. The industrial ecosystem enables rapid prototyping and scalable production, supported by localized access to CNC machining, servo systems, and food-grade material suppliers within a 50km radius.

Manufacturers in Jiaozuo and Zhengzhou specialize in grain product making machinery, benefiting from established logistics networks that reduce export lead times by 15–20% compared to offshore alternatives. Facilities typically operate vertical production lines capable of assembling 300–500 units per month, with average factory areas exceeding 2,000m². Buyers gain access to standardized models ranging from tabletop units to high-capacity commercial systems, alongside customization options for diameter (5–40cm), thickness (0.8–3mm), and output speed (600–1,800 pieces/hour).

How to Choose Fully Automatic Chapati Making Machine Suppliers?

Effective supplier evaluation requires systematic verification across technical, operational, and transactional dimensions:

Technical Compliance

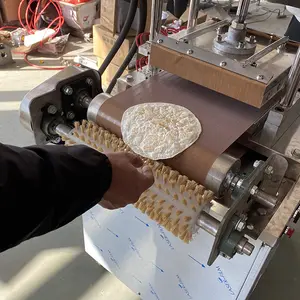

Confirm adherence to international safety and hygiene standards. While explicit ISO or CE certifications are not uniformly declared, prioritize suppliers offering food safety-level materials (e.g., SUS304 stainless steel) and documented electrical compliance (220V/50Hz or customized voltage). Request test reports on motor insulation class, heating element durability, and mold release performance under continuous operation.

Production Capability Audits

Assess infrastructure maturity through verifiable indicators:

- Minimum 1,000m² production area for dedicated assembly and testing zones

- In-house engineering support for customization (belt speed, mold shape, automation level)

- Integration of servo-controlled pressing and rolling mechanisms

Cross-reference listed product ranges with response time metrics—suppliers answering within ≤2 hours demonstrate higher operational responsiveness.

Transaction Safeguards

Utilize secure payment frameworks such as escrow services to mitigate risk. Evaluate reorder rates as a proxy for customer satisfaction; rates below 15% may indicate limited post-sale support or inconsistent quality. Prioritize suppliers with transparent pricing structures and verified delivery performance (target ≥97% on-time shipment rate). Pre-shipment inspection clauses should include functional testing of dough feeding, rolling, baking, and stacking cycles.

What Are the Best Fully Automatic Chapati Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jiaozuo Taoding Trading Co., Ltd. | Henan, CN | Grain Product Making Machines, Customization Options | US $540,000+ | 97% | ≤2h | 15% | $550–5,900 | 1 set |

| Henan Zhuodong Supply Chain Management Co., Ltd. | Henan, CN | Grain Product Making Machines (484) | US $20,000+ | 100% | ≤2h | <15% | $450–600 | 1 piece |

| Yongtao Group (Henan) Co., Ltd. | Henan, CN | Grain Product Making Machines (171) | - | - | ≤4h | - | $450–750 | 1 piece |

| YANN TECHNOLOGY LLC | Henan, CN | Grain Product Making Machines (2254) | - | - | ≤1h | - | $650–8,000 | 1 set |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Henan, CN | Grain Product Making Machines, Customization Options | US $130,000+ | 100% | ≤2h | <15% | $350–8,800 | 1 set |

Performance Analysis

Jiaozuo Taoding stands out for high online revenue ($540k+) and diversified pricing, catering to both entry-level and premium segments. Henan Zhuodong offers competitive pricing ($450–600) with perfect on-time delivery, ideal for cost-sensitive buyers seeking reliable volume procurement. Jiaozuo Dingchang combines 100% delivery reliability with extensive customization capabilities—including adjustable mold shapes, cooling systems, and noise reduction features—making it suitable for specialized bakery integrations. YANN TECHNOLOGY leads in product listing breadth (2,254 listings), signaling strong R&D activity, while maintaining sub-hour response times. Yongtao Group provides budget-friendly models but lags in delivery tracking and customer retention metrics.

FAQs

What is the typical MOQ for fully automatic chapati machines?

Most suppliers list a minimum order quantity of 1 set or 1 piece, enabling low-risk sampling. Bulk orders (10+ units) often unlock negotiated pricing and extended warranty terms.

How long does production and shipping take?

Standard lead time ranges from 15–30 days for production, depending on customization depth. Air freight delivers samples within 7–10 days; sea freight for full containers takes 25–40 days to major global ports.

Can I customize the machine for specific roti or tortilla dimensions?

Yes, multiple suppliers offer mold customization for diameter (up to 40cm), thickness (adjustable via roller gap), and shape (round, oval, square). Some provide multi-mold changers and programmable PLC interfaces for batch switching.

Do suppliers provide after-sales technical support?

Support levels vary. Top-tier suppliers document "good after-sales service" and offer remote troubleshooting. For critical deployments, request training videos, spare parts kits, and local technician contacts before purchase.

Are there energy-efficient models available?

Select models integrate servo motors and insulated heating chambers to reduce power consumption by 15–25%. Confirm input power ratings (typically 2.5–7kW) and thermal recovery efficiency when comparing high-throughput systems.