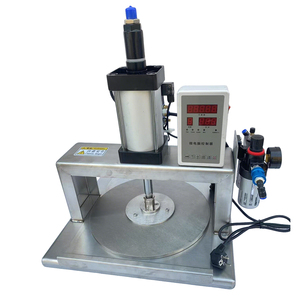

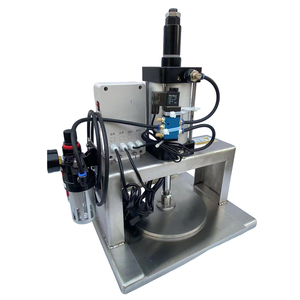

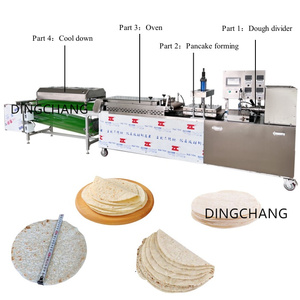

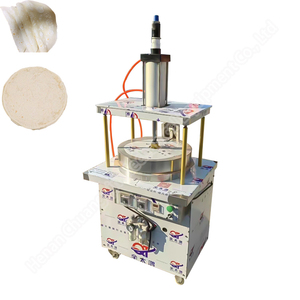

Semi Automatic Chapati Making Machine

1/14

1/14

1/8

1/8

1/16

1/16

1/21

1/21

1/15

1/15

1/13

1/13

About semi automatic chapati making machine

Where to Find Semi Automatic Chapati Making Machine Suppliers?

China remains the dominant hub for semi automatic chapati making machine manufacturing, with key production clusters concentrated in Henan and Jiaozuo regions. These industrial zones benefit from established food processing equipment ecosystems, integrating component suppliers, sheet metal fabricators, and thermal system engineers within close proximity. The concentration enables streamlined production cycles and rapid prototyping capabilities, particularly for flatbread machinery used in commercial kitchens and small-scale food enterprises.

Suppliers in these regions operate vertically integrated facilities capable of handling design, fabrication, heat treatment, and final assembly in-house. This integration reduces dependency on external vendors, cutting lead times by up to 25% compared to decentralized models. Buyers gain access to scalable production lines with monthly output capacities ranging from 200 to over 1,000 units per manufacturer. Localized supply chains also contribute to a 15–30% cost advantage over equivalent machinery produced in Southeast Asia or India, primarily due to lower material procurement and labor costs.

How to Choose Semi Automatic Chapati Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance and Quality Assurance

While formal certifications such as ISO 9001 or CE are not universally declared in available data, buyers should require documented evidence of quality control procedures. Prioritize suppliers that implement standardized testing protocols for critical components—especially heating plates, pressure rollers, and motor systems. For export compliance, confirm adherence to electrical safety standards (e.g., 110V/220V configurations) and material hygiene requirements (food-grade stainless steel construction).

Production Capability Assessment

Evaluate infrastructure indicators including factory size, workforce specialization, and R&D capacity. Key benchmarks include:

- Minimum facility area exceeding 3,000m² to support batch production

- In-house engineering teams for customization and troubleshooting

- Capabilities in CNC machining, welding, and surface finishing

Cross-reference delivery performance metrics: top-tier suppliers maintain on-time delivery rates above 98%, with response times under 3 hours indicating strong customer service infrastructure.

Customization and Transaction Safeguards

Most leading suppliers offer customization options covering color, material thickness, logo imprinting, packaging, and mechanical adjustments (e.g., diameter range, pressing force). Confirm whether modifications impact lead time or minimum order quantity (MOQ). Utilize secure payment mechanisms such as escrow services, and request product videos or third-party inspection reports before shipment. Sample testing is recommended to validate dough consistency, cooking uniformity, and cycle speed prior to bulk orders.

What Are the Best Semi Automatic Chapati Making Machine Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Henan Kellen Machinery Equipment Co., Ltd. | Henan, CN | Custom Manufacturer | US $360,000+ | 96% | ≤3h | <15% | Multiple models ($500–$7,000) | Color, material, size, logo, packaging |

| Jiaozuo Forward Machine Co., Ltd. | Jiaozuo, CN | Multispecialty Supplier | US $190,000+ | 99% | ≤4h | <15% | Bread & snack machines ($109–$1,995) | Logo, graphic |

| Zhengzhou Qiongdan Machinery Co., Ltd. | Zhengzhou, CN | Unverified | US $10,000+ | 100% | ≤2h | <15% | Flatbread & grain processing | Limited public detail |

| Henan Chuangqin Mechanical Equipment Co., Ltd. | Henan, CN | Multispecialty Supplier | US $370,000+ | 100% | ≤2h | 15% | Wide price band ($128–$1,900) | Color, shape, size, thickness, mold, packaging |

| Jiaozuo Newest Machinery Co., Ltd. | Jiaozuo, CN | Unverified | US $200,000+ | 98% | ≤3h | <15% | Diverse food processing line | Not specified |

Performance Analysis

Henan-based suppliers demonstrate strong market presence with higher online revenue and comprehensive customization offerings. Henan Chuangqin stands out with a 100% on-time delivery rate, sub-2-hour response time, and extensive configurability, positioning it as a preferred partner for tailored solutions. Jiaozuo Forward offers competitive pricing starting at $109 per set, ideal for budget-conscious buyers seeking entry-level automation. Zhengzhou Qiongdan achieves perfect delivery performance despite lower reported revenue, suggesting niche specialization or recent market entry. Reorder rates remain below 15% across most suppliers, indicating room for improvement in long-term customer retention or after-sales support.

FAQs

What is the typical MOQ for semi automatic chapati making machines?

Most suppliers list a minimum order quantity of 1 set, enabling low-risk sampling and pilot testing. Some models may require 2 sets as MOQ, particularly for newer or customized configurations.

What are common lead times for production and shipping?

Standard production lead time ranges from 15 to 30 days after order confirmation. Air freight delivery takes 5–10 days; sea freight requires 25–40 days depending on destination port and customs clearance procedures.

Can suppliers provide machine specifications in English?

Yes, reputable suppliers typically provide technical documentation, operation manuals, and wiring diagrams in English. Confirm language support during initial inquiries to avoid communication gaps.

Do manufacturers offer after-sales service or warranties?

Warranty terms vary by supplier but commonly range from 6 months to 1 year for core components. Clarify coverage scope, spare parts availability, and technical support channels before purchase.

How to verify product functionality before ordering?

Request video demonstrations showing machine operation, dough feeding, rolling, and baking cycles. For high-volume procurement, arrange third-party inspections or visit the factory to audit production lines and test sample units under real conditions.