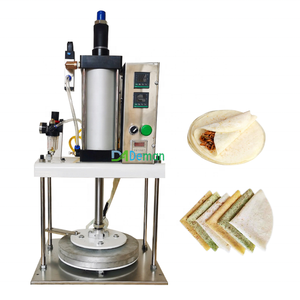

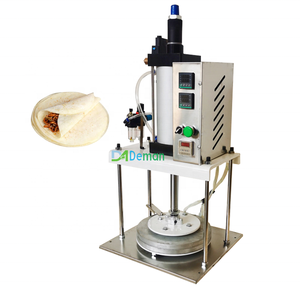

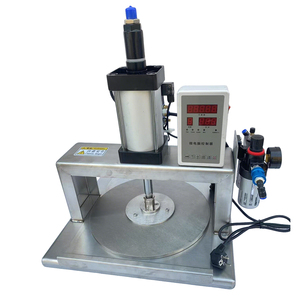

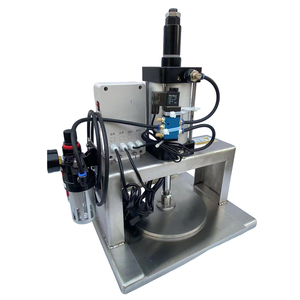

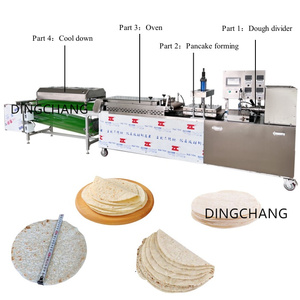

Semi Automatic Chapati Machine

Top sponsor listing

Top sponsor listing

About semi automatic chapati machine

Where to Find Semi Automatic Chapati Machine Suppliers?

China remains the global epicenter for semi automatic chapati machine manufacturing, with key production clusters concentrated in Henan and surrounding regions. These industrial hubs benefit from mature supply chains for food processing machinery components, including heating elements, rollers, motors, and control panels. Zhengzhou, the provincial capital of Henan, serves as a logistical nexus, enabling efficient export operations across Southeast Asia, the Middle East, and Africa—markets with high demand for flatbread automation.

The region’s specialization in grain product making machines supports vertical integration, allowing suppliers to offer competitive pricing and rapid prototyping. With thousands of listings dedicated to chapati and tortilla equipment, manufacturers leverage shared infrastructure for metal fabrication, electrical assembly, and packaging. This ecosystem reduces lead times for standard models to 15–25 days and enables scalable production runs exceeding 500 units per month. Buyers gain access to a diversified supplier base capable of fulfilling both commercial kitchen installations and retail distribution contracts.

How to Choose Semi Automatic Chapati Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify adherence to international safety standards such as CE or IEC for electrical systems, particularly for markets in Europe and North America. Ensure machines are constructed with food-grade materials (e.g., stainless steel contact surfaces) compliant with hygiene regulations. Demand documentation on motor specifications (typically 1–3 HP), temperature control range (150°C–300°C), and hourly output capacity (ranging from 600–1,800 pieces/hour depending on model).

Production and Customization Capability

Assess supplier flexibility through available customization options:

- Diameter adjustment (15–25 cm common)

- Thickness control (1–5 mm precision)

- Power configurations (single-phase vs. three-phase)

- Voltage compatibility (110V/220V/380V)

- OEM branding (logo, color, labeling)

Cross-reference stated capabilities with actual product listings and confirm whether tooling molds or pressing rollers can be modified for regional roti or tortilla variations.

Quality Assurance and Transaction Security

Prioritize suppliers with verifiable on-time delivery rates above 97% and response times under 4 hours. Evaluate quality management practices by reviewing after-sales service policies, warranty terms (typically 12 months), and availability of spare parts. Utilize secure payment mechanisms that link disbursement to shipment verification. Pre-shipment inspections—either third-party or via video audit—are recommended to validate build quality before dispatch.

What Are the Best Semi Automatic Chapati Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Jiaozuo Taoding Trading Co., Ltd. | Grain Product Making Machines (6,656) | 97% | <15% | ≤2h | US $540,000+ | Color, shape, thickness, motor speed, size, material, logo, cable, capacity, pattern, mold, weight, diameter |

| Henan Orange Industry Co.,Ltd. | Not specified | 100% | 21% | ≤2h | US $410,000+ | Color, thickness, weight, packaging, label, capacity, diameter, material, size, logo, graphic, compressor, dimensions |

| Zhengzhou Deman Machinery Co., Ltd. | Grain Product Making Machines (113) | 100% | <15% | ≤4h | US $50,000+ | Limited data; focus on gas-powered variants and home-use models |

| Zhengzhou Qiongdan Machinery Co., Ltd. | Other Snack Machines (813), Grain Product Making Machines (711) | 100% | <15% | ≤2h | US $10,000+ | Multiple models with variable roller sizes and pancake/chapati versatility |

| CQ MECHANICAL TECHNOLOGY INC | Grain Product Making Machines (13,179) | - | - | ≤2h | - | Broad listing presence; emphasis on multi-functional pressing and sheet-forming applications |

Performance Analysis

Henan Orange Industry stands out with a 100% on-time delivery rate and a 21% reorder rate, indicating strong customer retention despite higher price points (up to $2,099). Jiaozuo Taoding Trading leads in revenue volume ($540,000+) and offers extensive customization, making it suitable for buyers seeking OEM partnerships. CQ MECHANICAL TECHNOLOGY INC operates at scale with over 13,000 listings in grain machinery, though transparency on performance metrics is limited. Suppliers based in Zhengzhou demonstrate strong technical diversity, often offering dual-function machines capable of producing both chapati and tortilla or pancake variants. For high-volume procurement, prioritize companies with documented delivery reliability and multi-parameter customization support.

FAQs

What is the typical MOQ for semi automatic chapati machines?

Most suppliers list a minimum order quantity (MOQ) of 1 set, facilitating sample testing and small business adoption. Bulk pricing typically applies from 5 units onward, with discounts varying by configuration and customization level.

What are the average lead times?

Standard orders are fulfilled within 15–25 days after confirmation. Customized units may require an additional 7–10 days depending on mechanical modifications or branding requirements.

Do suppliers provide technical support and installation guides?

Yes, most suppliers include operation manuals and basic troubleshooting documentation. Some offer remote video assistance for setup. Confirm language availability (English, Arabic, etc.) prior to ordering if deploying in non-Chinese-speaking regions.

Can these machines handle different dough types?

High-end models support wheat, maize, and multigrain doughs with adjustable pressure and heat settings. Verify compatibility with local formulations during sampling, especially for high-fiber or hydrated dough variants.

Are spare parts readily available?

Leading suppliers stock critical wear components such as Teflon-coated rollers, heating plates, and drive belts. Inquire about part numbering systems and estimated replacement costs before finalizing contracts.