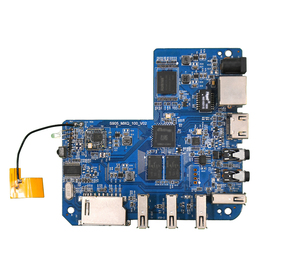

Circuit Tech Assembly

Top sponsor listing

Top sponsor listing

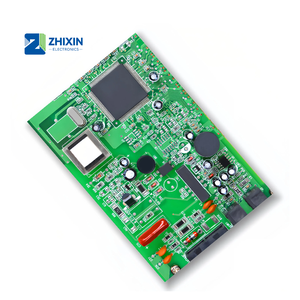

About circuit tech assembly

Where to Find Circuit Tech Assembly Suppliers?

China remains the global epicenter for circuit tech assembly manufacturing, with Shenzhen and Shanghai forming key industrial hubs for printed circuit board (PCB) and PCBA production. These regions host vertically integrated facilities capable of delivering one-stop services—from design and component sourcing to SMT processing, testing, and final assembly. Shenzhen alone accounts for over 60% of China’s electronics contract manufacturers, supported by a dense ecosystem of material suppliers, logistics providers, and technical talent.

The concentration enables rapid prototyping (as fast as 24–72 hours) and scalable batch production, with lead times averaging 7–15 days for small to medium volumes. Localized supply chains reduce component procurement delays and lower overall costs by 20–30% compared to Western alternatives. Buyers benefit from flexible MOQs—some suppliers support single-piece orders—while maintaining compliance with international standards such as RoHS and IPC-A-610 for electronic assemblies.

How to Choose Circuit Tech Assembly Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

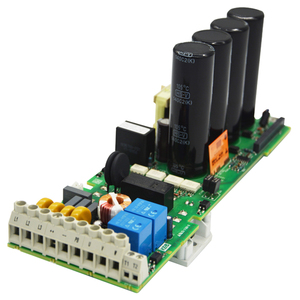

Verify the supplier’s ability to handle required PCB types: multilayer, rigid-flex, high-frequency, or FPC. Confirm in-house SMT lines, BOM sourcing capabilities, and support for value-added processes like IC programming, box-build assembly, and reverse engineering. Prioritize suppliers offering full turnkey solutions, including component procurement and final packaging.

Quality Assurance and Compliance

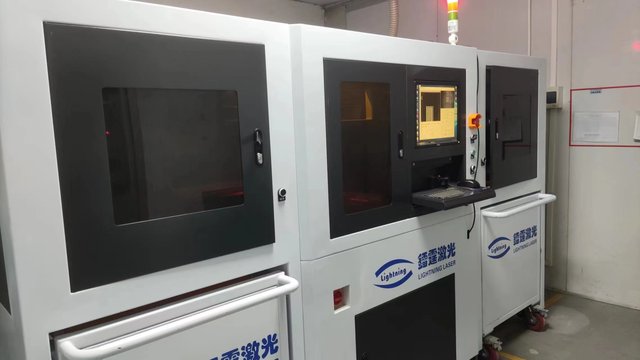

Ensure adherence to recognized quality management systems such as ISO 9001. For export-oriented buyers, confirm RoHS and REACH compliance documentation. Review test methodologies—automated optical inspection (AOI), X-ray inspection, and functional testing—are critical indicators of process rigor. Request access to sample reports or facility audit videos where available.

Performance Metrics and Responsiveness

Analyze verified performance data:

- On-time delivery rate ≥98%

- Average response time ≤2 hours

- Reorder rate >30% indicating customer retention

- Support for customization (e.g., Gerber file processing, color labeling, logo printing)

Cross-reference these metrics with order volume history and product listing diversity to assess scalability and specialization depth.

What Are the Best Circuit Tech Assembly Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Notable Offerings |

|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | PCBA, Multilayer PCB, FPC, Rigid-Flex, High Frequency PCB | Limited data | 100% | ≤2h | 66% | US $1,000+ | One-stop PCB/PCBA design and manufacturing; extensive product listings across PCB variants |

| Shenzhen Xuyuxin Technology Co., Ltd. | PCBA, Other PCB & PCBA | Limited data | 100% | ≤1h | - | - | Rapid-response OEM SMT processing; wireless charging PCBA solutions |

| Shenzhen Wonstron Technology Co., Ltd. | PCBA, Circuit Board Manufacturing | BOM sourcing, reverse engineering, labeling, packaging, IC programming | 100% | ≤2h | 20% | US $260,000+ | Comprehensive customization; strong focus on component sourcing and design services |

| Jieliang Electronic Technology Shanghai Co.,ltd. | PCBA, Camera Modules | Limited data | 100% | ≤4h | - | - | OEM digital scale and smart home controller assembly; quick-turn Shanghai-based production |

| Tecoo Electronics Co., Ltd. | PCBA, Integrated Circuit Assembly | PCB cloning, global component sourcing, housing assembly, IC programming, box-build | 98% | ≤2h | 35% | US $460,000+ | Turnkey manufacturing with robust after-sales support; high reorder rate indicates service reliability |

Performance Analysis

Toptek Pcb and Shenzhen Xuyuxin demonstrate exceptional responsiveness and perfect on-time delivery records, making them suitable for urgent or time-sensitive projects. Shenzhen Wonstron and Tecoo Electronics stand out for advanced customization, including reverse engineering and full BOM management—critical for legacy system replication or complex designs. Tecoo’s 35% reorder rate reflects strong client satisfaction in turnkey execution. While Jieliang Electronic offers niche expertise in camera modules and automotive seating electronics, its longer response window may affect agility in fast-paced development cycles.

FAQs

How to verify circuit tech assembly supplier reliability?

Validate certifications (ISO 9001, RoHS), request sample boards for quality inspection, and analyze historical performance metrics such as on-time delivery and reorder rates. Conduct virtual factory audits to observe SMT line operations and quality control checkpoints. Use structured questionnaires to assess component traceability and failure mitigation protocols.

What is the typical MOQ and lead time?

MOQ varies widely: some suppliers offer 1-piece prototyping, while others require 100–500 units for cost-effective runs. Standard lead time ranges from 5–7 days for samples and 10–15 days for production batches. Turnkey orders involving component procurement may extend timelines by 3–5 days depending on part availability.

Can suppliers handle component sourcing and BOM management?

Yes, leading suppliers provide full BOM analysis, alternative component recommendations, and direct procurement from authorized distributors. Some offer obsolescence mitigation strategies and counterfeit prevention measures through audited supply chains. Confirm sourcing scope during initial engagement to avoid downstream delays.

Do manufacturers support design-for-manufacturability (DFM) reviews?

Most professional assemblers conduct free DFM checks upon receiving Gerber files and BOMs. This includes evaluating solder mask clearance, pad layout, and component placement accuracy to minimize rework. Proactive DFM feedback reduces defect rates and accelerates first-pass yield.

How are quality issues resolved post-delivery?

Established suppliers implement corrective action procedures (CAPA) for defective units. Buyers should clarify warranty terms, return material authorization (RMA) processes, and liability coverage before shipment. Third-party inspection services can be engaged at destination for high-value consignments.