Clear Ice Cube Maker Machine

CN

CN

About clear ice cube maker machine

Where to Find Clear Ice Cube Maker Machine Suppliers?

China remains the central hub for manufacturing clear ice cube maker machines, with key supplier clusters concentrated in industrial provinces such as Henan, Jiangsu, and Zhejiang. These regions host vertically integrated supply chains encompassing refrigeration engineering, mold fabrication, and food-grade material processing—critical components in producing high-clarity ice systems. Zhengzhou and Nantong have emerged as specialized centers for commercial-grade ice equipment, offering scalable production lines capable of delivering units ranging from compact countertop models to industrial 1-ton-per-day systems.

The regional ecosystems support rapid prototyping and cost-efficient mass production, leveraging localized access to compressors, evaporators, and stainless steel components. This integration reduces lead times by up to 25% compared to offshore alternatives. Buyers benefit from flexible MOQs—from single-unit orders for niche distributors to container-scale procurement for hospitality chains—supported by mature export logistics networks. Average delivery cycles range from 15–30 days post-deposit, depending on customization scope and order volume.

How to Choose Clear Ice Cube Maker Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical & Quality Standards

Verify compliance with international safety and performance benchmarks. While not all suppliers hold formal ISO 9001 or CE certifications, consistent on-time delivery rates above 97% and response times under 3 hours indicate operational discipline. For food-service applications, ensure materials meet FDA or equivalent food-contact standards, particularly in water circulation systems and ice trays. Request documentation on compressor efficiency (e.g., Copeland or Danfoss usage), condenser types (air/water-cooled), and defrost mechanisms.

Production Capacity and Customization

Assess scalability through available product variants and customization options. Leading suppliers offer configurable parameters including:

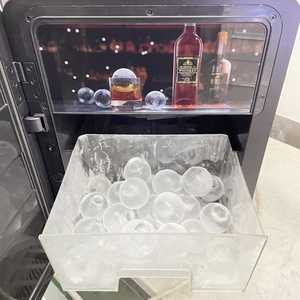

- Ice clarity method (directional freezing vs. filtered circulation)

- Cube size and shape (standard cubic, jumbo, spherical, cylindrical)

- Output capacity (10kg/day to 1,000kg/day)

- OEM services: color, logo, packaging, voltage (110V/220V), plug type

Confirm whether molds are injection-molded silicone or polycarbonate, and if housings use stainless steel or ABS plastic.

Transaction Security and After-Sales Support

Prioritize suppliers with verifiable performance metrics: reorder rates above 20%, on-time shipment consistency (>98%), and transparent communication. Utilize secure payment frameworks where possible, especially for high-value machinery. Sample testing is recommended—evaluate ice clarity, cycle time, noise levels (ideally below 45 dB), and energy consumption before full-scale orders. Inquire about warranty terms (typically 1 year) and availability of spare parts.

What Are the Best Clear Ice Cube Maker Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Taizy Trading Co., Ltd. | Industrial & Commercial Clear Ice Makers | $1,900–15,000 | 1 set | 100% | ≤3h | 20% | Color, material, size, logo, packaging | US $20,000+ |

| Nantong Wuding Technology Co., Ltd. | WICE Brand Commercial Ice Machines | $180–3,850 | 1 set | 97% | ≤3h | 17% | Limited (model-specific) | US $60,000+ |

| Yuyao Haohong Electrical Appliance Co., Ltd. | Portable & Countertop Ice Makers | $44.90–139.90 | 1–2 pieces | 100% | ≤2h | <15% | Basic (color, packaging) | US $170,000+ |

| Xiamen Theone Household Products Co., Ltd. | Reusable Fake Ice Cubes (Non-Electric) | $0.11–21.62 | 3–500 pcs | 98% | ≤2h | <15% | Color, shape, size, design, logo | US $10,000+ |

| Yiwu Ziming Commodity Co., Ltd. | Silicone Ice Molds & Reusable Ice Simulators | $0.18–6.00 | 3–32 pieces | 100% | ≤3h | <15% | Shape, size, logo, packaging | US $2,000+ |

Performance Analysis

Zhengzhou Taizy stands out for industrial buyers requiring certified, large-capacity systems, supported by strong after-sales engagement (20% reorder rate) and comprehensive customization. Nantong Wuding offers competitive pricing across multiple commercial tiers, though slightly lower delivery reliability (97%) warrants closer monitoring during peak seasons. Yuyao Haohong dominates the consumer segment with high-volume portable units, backed by extensive online sales validation (US $170,000+ revenue). Suppliers like Xiamen Theone and Yiwu Ziming focus on non-electric reusable ice simulants—suitable for display or decorative use but not functional ice production.

For procurement targeting authentic clear ice generation, prioritize companies specializing in refrigeration-based systems over those marketing acrylic or gel-filled substitutes. Cross-reference product descriptions with technical specifications to avoid misclassification.

FAQs

How do clear ice cube maker machines work?

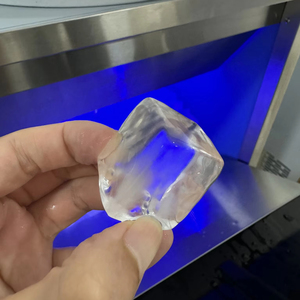

These machines use directional freezing technology, where water freezes slowly from the top down, pushing impurities and air bubbles outward. This process results in visually transparent ice cubes. Some models integrate advanced filtration to enhance clarity and reduce scaling.

What is the typical MOQ for commercial clear ice makers?

Most suppliers require a minimum order of 1 set for initial purchases, enabling low-risk sampling. Bulk pricing typically applies at 5+ units, with discounts varying based on output capacity and configuration.

Are samples available for testing?

Yes, many suppliers allow sample orders, often at a premium price. Expect lead times of 7–15 days for standard models. Customized prototypes may take 20–30 days, including tooling adjustments.

Can suppliers provide OEM/ODM services?

Leading manufacturers offer full OEM support—including custom branding, housing colors, user interface labels, and packaging design. MOQs for branded units typically start at 50 sets, though some accept lower volumes for repeat customers.

What are the common power and installation requirements?

Residential and small commercial units operate on 110V/60Hz or 220V/50Hz, with water line connections optional depending on model. Larger industrial systems require dedicated circuits, floor drainage, and sometimes external condensers. Confirm electrical specs and ambient operating temperatures (usually 0°C to 43°C) prior to integration.