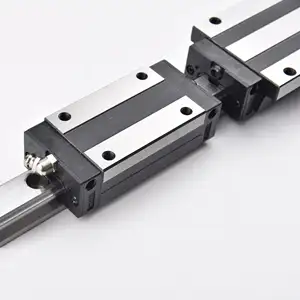

Cnc Machine Linear Rail

Top sponsor listing

Top sponsor listing

About cnc machine linear rail

Where to Find CNC Machine Linear Rail Suppliers?

China remains the global epicenter for precision motion component manufacturing, with key supplier clusters concentrated in Zhejiang, Shandong, and Sichuan provinces. These regions host vertically integrated industrial ecosystems specializing in linear motion systems, supported by localized steel processing, CNC machining, and bearing production networks. Lishui in Zhejiang has emerged as a hub for high-precision linear guides, where proximity to raw material suppliers reduces input costs by 12–18% compared to offshore alternatives. Chengdu and Jinan contribute strong engineering capabilities, particularly in custom rail configurations and gantry-integrated solutions.

The regional supply chains enable rapid prototyping and scalable production, with many manufacturers operating end-to-end facilities that include heat treatment, grinding, and preloading calibration. This integration supports lead times averaging 15–25 days for standard rails and 30–40 days for customized lengths or load-specific designs. Buyers benefit from flexible MOQs—ranging from 1 meter to full system kits—and access to modular product lines compatible with major international standards (e.g., HIWIN, THK, PMI).

How to Choose CNC Machine Linear Rail Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to ISO 9001 quality management systems as a baseline. For export markets, CE marking and RoHS compliance indicate regulatory readiness. Request test reports on hardness (HRC 58–62 for hardened rails), geometric accuracy (±0.02mm/m straightness tolerance), and load capacity validation. Reputable suppliers provide documentation on ball/roller recirculation testing and corrosion resistance, especially for sealed or rust-proof models.

Production Capacity Assessment

Evaluate core manufacturing competencies through the following indicators:

- In-house grinding and precision machining capabilities for rail flatness and parallelism control

- Customization infrastructure for length cutting, hole drilling, surface coating, and labeling

- Minimum facility size of 2,000m² with dedicated clean assembly zones

Cross-reference online revenue metrics and order fulfillment rates: suppliers with >$300,000 annual digital turnover typically maintain stable production lines and inventory buffers.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial transactions. Prioritize suppliers with verified response times under 4 hours and on-time delivery performance exceeding 97%. Conduct sample testing to validate dimensional accuracy, smoothness of travel, and preload consistency before scaling orders. Request CAD drawings or compatibility charts to ensure interchangeability with existing CNC machine components.

What Are the Best CNC Machine Linear Rail Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Chengdu Fuyu Technology Co., Ltd. | Sichuan, CN | Linear Guides, Linear Robots, CNC Controllers, Limit Switches | US $320,000+ | 97% | ≤2h | 19% | Yes (length, size, logo, packaging, material) |

| Lishui City Yongrun Precision Machinery Co., Ltd. | Zhejiang, CN | Linear Guides, Ball Screws, Linear Bearings, Guide Blocks | US $40,000+ | 100% | ≤3h | 16% | Limited (standard configurations) |

| Lishui Zhengda Precision Machinery Co., Ltd. | Zhejiang, CN | Linear Guides, Ball Screws, Shafts, Bearings | US $2,000+ | 100% | ≤1h | <15% | Basic (size, length) |

| Shandong Jingrui Transmission Technology Co., Ltd. | Shandong, CN | Linear Guides, Rack Gears, Ball Screws, Drag Chains | US $30,000+ | 94% | ≤3h | 26% | Yes (rail units, size, configuration) |

| Jinan Lihan Numerical Control Technology Co., Ltd. | Shandong, CN | High-Precision Linear Rails, CNC Aluminum Rails, Sliders | US $660,000+ | 99% | ≤4h | 30% | Yes (size, length, logo, packaging) |

Performance Analysis

Jinan Lihan leads in reorder volume and customization responsiveness, backed by strong export performance and compatibility with OEM branding needs. Chengdu Fuyu offers broad product integration, including PLCs and CNC controllers, making it suitable for turnkey motion system sourcing. Lishui-based suppliers (Yongrun and Zhengda) demonstrate perfect on-time delivery records and sub-3-hour response times, reflecting efficient small-batch processing. However, lower reorder rates suggest limited post-sale engagement or niche market positioning. For high-volume procurement, prioritize suppliers with proven scalability (evidenced by revenue >$300k) and multi-point quality controls.

FAQs

How to verify CNC linear rail supplier credibility?

Validate certifications through official registries and request factory audit reports or video walkthroughs of grinding and assembly lines. Analyze transaction history, focusing on consistent delivery performance and customer feedback related to dimensional accuracy and noise levels during operation.

What is the typical sampling timeline for linear rails?

Standard samples are produced within 7–14 days. Customized rails requiring specific lengths, preloaded blocks, or anti-corrosion treatments may take 20–30 days. Air shipping adds 5–10 days depending on destination.

Can suppliers provide globally compliant packaging and labeling?

Yes, leading suppliers support multilingual labeling, export-grade wooden crate packaging, and compliance marking (CE, EAC, etc.). Confirm inclusion of technical datasheets and mounting instructions in requested languages prior to shipment.

Do suppliers offer free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to future bulk orders. Otherwise, expect to pay 50–100% of the unit cost, which may be credited toward first production runs.

How to initiate a customization request for linear rails?

Submit detailed specifications including rail type (square/round), model (HGR, SBR, HGH), length, block count, accuracy grade (C0–C5), preload class, material (bearing steel/aluminum), and any branding or packaging requirements. Suppliers with customization capabilities typically respond with technical confirmation within 48 hours.