Cnc Machine Used For Which Type Of Production

About cnc machine used for which type of production

Where Are Used CNC Machines Sourced for Industrial Production?

China remains a dominant hub for the global trade of used CNC machines, with key supplier clusters concentrated in Jiangxi and Gansu provinces. These regions host specialized machinery reconditioning centers that source, refurbish, and export pre-owned CNC equipment to manufacturing sectors worldwide. Longnan and Ganzhou cities serve as operational bases for suppliers offering cost-effective alternatives to new machinery, particularly vertical machining centers, CNC lathes, and multi-axis milling systems.

The regional ecosystem supports rapid deployment of second-hand industrial assets through integrated logistics networks and technical assessment facilities. Suppliers typically operate from compact but efficient workshops ranging from 500–2,000m², enabling quick inspection cycles and streamlined export processing. Buyers benefit from localized access to component inventories and skilled technicians capable of performing functional diagnostics and minor upgrades prior to shipment. This infrastructure facilitates lead times averaging 15–30 days for ready-to-ship units, with pricing structures reflecting 40–70% savings compared to equivalent new models.

How to Evaluate Suppliers of Used CNC Machines?

Procurement decisions should be guided by structured verification protocols focused on machine condition, transaction reliability, and operational transparency.

Technical Assessment

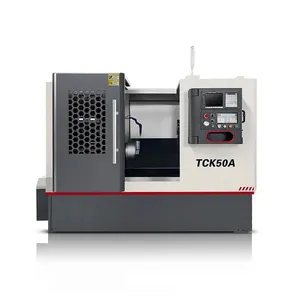

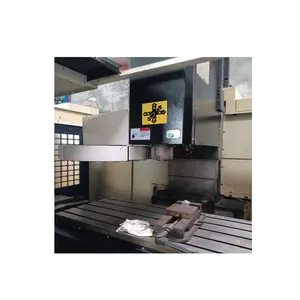

Verify machine specifications including axis configuration (3-axis, 4-axis, or 6-axis), spindle type, control system brand (e.g., Fanuc, Mitsubishi), and original manufacturing year. Request maintenance logs or service history where available. High-performance units such as Mikron HSM600U or Makino V33 models require confirmation of calibration status and tool wear metrics. For turning applications, assess chuck size, turret capacity, and live tooling compatibility in CNC lathes.

Supplier Performance Indicators

Analyze behavioral metrics derived from transaction patterns:

- On-time delivery rates ≥98% indicate reliable order execution

- Response times ≤4 hours suggest proactive communication capacity

- Reorder rates above 30% reflect buyer satisfaction and repeat engagement

- Minimum order quantities typically range from 1 unit to 1 set, accommodating small-scale procurement

Cross-reference listed product prices against market benchmarks—used vertical machining centers generally fall within $9,000–$30,000, while high-precision or larger-format machines may exceed $100,000.

Transaction Security Measures

Prioritize suppliers offering verifiable performance histories and transparent revenue reporting. While formal certifications (ISO, CE) are rarely documented for individual used machines, insist on video inspections or factory walk-throughs to validate equipment condition. Utilize secure payment mechanisms that allow release upon destination verification. Conduct sample testing when feasible, focusing on positional accuracy, surface finish quality, and thermal stability during extended operation.

Which Companies Supply Used CNC Machines for Production Applications?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Longnan City Brotherholding Protective Equipment Co., Ltd. | Machining Centre, Manual Lathe, Injection Molding Machine | $9,000–$12,900 | 1 set | 100% | ≤4h | 100% | $5,000+ |

| Ganzhou Fuxing Technology Co., Ltd. | Machining Centre, CNC Lathe, Cylindrical Grinding Machine | $8,850–$130,000 | 1 set | 100% | ≤5h | 75% | $20,000+ |

| BELLA GLOBAL CO., LTD. | CNC Milling Machines, CNC Lathe, Manual Lathe | $5,500–$42,000 | 1 piece | 100% | ≤4h | <15% | - |

| Longnan County Shengming Machinery Equipment Co., Ltd. | Machining Centre, Injection Molding Machines, Manual Lathe | $9,999–$37,000 | 1 set | 100% | ≤4h | 37% | $30,000+ |

| Ganzhou Fuxing Intelligent Equipment Co., Ltd. | Machining Centre, CNC Lathe, Manual Lathe | $4,600–$22,899 | 1 unit | 100% | ≤3h | - | - |

Performance Analysis

Suppliers like Ganzhou Fuxing Technology offer the broadest range of high-end used equipment, including precision machines from brands such as Mori Seiki and Mikron, supported by strong reorder rates (75%) and higher online transaction volumes ($20,000+). Longnan-based firms demonstrate exceptional reliability with perfect on-time delivery records and full reorder fulfillment, indicating consistent customer trust. BELLA GLOBAL presents entry-level options with lower price points (from $5,500), though limited reorder data suggests potential gaps in post-sale performance. Ganzhou Fuxing Intelligent Equipment stands out for responsiveness (≤3h) and competitive pricing, making it suitable for time-sensitive sourcing needs despite unreported revenue metrics.

FAQs

What types of production use second-hand CNC machines?

Used CNC machines support a wide range of manufacturing processes including metal cutting, mold making, automotive part fabrication, aerospace components, and custom prototyping. Vertical machining centers are commonly deployed for milling operations in medium-batch production, while CNC lathes serve high-precision turning tasks in shaft, bushing, and flange manufacturing.

What is the typical lead time for used CNC machine delivery?

Lead times average 15–30 days after order confirmation, assuming immediate availability and standard export documentation. Additional delays may occur if reconditioning, calibration, or disassembly/packaging is required. Air freight reduces transit time but increases cost significantly; sea freight remains optimal for heavy machinery.

Can used CNC machines be customized before shipment?

Limited customization is possible, primarily involving control parameter adjustments, tooling package selection, or basic software updates. Structural modifications or major component replacements are uncommon due to logistical constraints. Buyers should confirm machine readiness status and request pre-shipment videos to verify configuration alignment.

Do suppliers provide technical support after delivery?

Post-delivery support varies widely. Some suppliers offer remote guidance for setup and commissioning, while others limit assistance to documentation provision. It is advisable to clarify support scope prior to purchase and consider engaging local service providers for installation and training.

How to assess the remaining service life of a used CNC machine?

Evaluate based on reported operating hours, spindle condition, ball screw wear, and control system integrity. Machines under 10 years old with documented maintenance histories typically retain 5–8 years of productive life under moderate usage. Infrared thermography and vibration analysis reports can further inform longevity estimates if available.