Cnc Machining Is A Type Of

Top sponsor listing

Top sponsor listing

About cnc machining is a type of

Where to Find CNC Machining Suppliers?

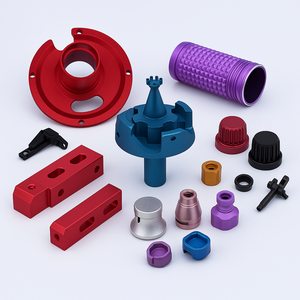

CNC machining is a type of subtractive manufacturing process that uses computer-controlled tools to remove material from a workpiece, producing high-precision components. China remains the global hub for CNC machining services, with concentrated supplier clusters in Guangdong and Fujian provinces. Shenzhen, within Guangdong, hosts a dense ecosystem of precision engineering firms supported by advanced supply chains for metals, polymers, and surface treatments. Xiamen in Fujian has emerged as a center for integrated fabrication services, combining CNC with sheet metal forming, casting, and molding.

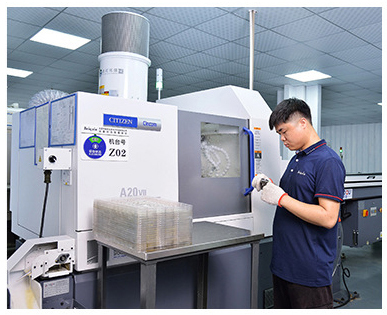

These industrial zones enable rapid prototyping and scalable production through vertically integrated workshops equipped with 3-, 4-, and 5-axis CNC systems. Suppliers typically operate lean production models with average lead times of 10–20 days for custom parts. Buyers benefit from localized access to raw materials—particularly aluminum, stainless steel (e.g., SS304), titanium, and engineering plastics—reducing material procurement delays. The proximity of secondary processing providers (anodizing, plating, chroming, labeling) allows for end-to-end part finishing within single-sourcing networks, improving turnaround efficiency by up to 35% compared to fragmented international sourcing.

How to Choose CNC Machining Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm availability of multi-axis CNC systems (minimum 3-axis, preferred 5-axis for complex geometries). Evaluate whether suppliers support both milling and turning operations, along with secondary processes such as welding, anodizing, or laser engraving. Review digital design compatibility—reputable providers accept STEP, IGES, DWG, and PDF drawings, and offer DFM (Design for Manufacturability) feedback within 24–72 hours.

Production Infrastructure Assessment

Assess core operational metrics:

- Facility size indicative of scalability (suppliers with ≥5,000m² demonstrate higher capacity)

- In-house tooling and mold-making capabilities for full process control

- Integration of CAD/CAM/CAE software with shop-floor CNC machines

Cross-reference equipment claims with on-time delivery performance (target ≥95%) and response time (≤6 hours, ideally ≤2 hours).

Quality & Transaction Assurance

Prioritize suppliers with ISO 9001 certification or equivalent quality management systems. While not all list formal certifications, consistent on-time delivery rates above 95% and reorder rates exceeding 25% serve as proxy indicators of reliability. Request evidence of inspection protocols, including first-article inspection reports (FAIR), coordinate measuring machine (CMM) data, and visual quality checklists. Utilize secure payment mechanisms where possible, especially for initial orders, to mitigate fulfillment risk.

What Are the Best CNC Machining Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Materials Supported | Min Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Holy Precision Manufacturing Co., Limited (zhongshan) | Machining Services, Sheet Metal Fabrication, Casting, Moulds | 84% | ≤6h | 41% | US $310,000+ | Yes | Steel, Titanium, Aluminum, Metal Alloys | 1–100 pcs |

| Perfect Goods Prototype Co., Ltd. | CNC Machining, Wood/Bamboo Parts, Spinning Components | 96% | ≤3h | 26% | US $560,000+ | Yes | Maple, SS304, Wood, Metals | 1 pc |

| Shenzhen Hongxiangsheng Technology Co., Ltd. | Machining Services, Bolts, Nuts, Sheet Metal | 100% | ≤2h | 25% | US $1,000+ | Yes | Stainless Steel, General Metals | 1 pack |

| Shenzhen Rapid Manufacturing Co., Ltd. | 5-Axis CNC, Turning, Milling, Prototypes | 100% | ≤5h | - | - | Yes | Metal (Unspecified) | 1–10 units |

| Xiamen Fuhongzhou Machinery Co., Ltd. | Machining, Forging, Sheet Metal, Casting, Moulds | 80% | ≤2h | 37% | US $130,000+ | Yes | Aluminum, Stainless Steel, Mechanical Alloys | 1–100 pcs |

Performance Analysis

Shenzhen-based suppliers dominate in delivery reliability, with two achieving 100% on-time performance and sub-5-hour response times—critical for urgent prototyping or replacement part orders. Perfect Goods Prototype stands out for low MOQ flexibility (down to 1 piece) and diverse material handling, including wood and bamboo, indicating niche capability beyond standard metal machining. Holy Precision and Xiamen Fuhongzhou offer broader service integration (casting, forging, molds), making them suitable for complex assemblies. Despite lower on-time delivery (80%), Xiamen Fuhongzhou’s 37% reorder rate suggests strong customer satisfaction post-delivery. Newer entrants without revenue disclosure require additional due diligence but may offer competitive pricing for small-volume trials.

FAQs

What materials can be used in CNC machining?

Common materials include aluminum alloys (6061, 7075), stainless steel (304, 316), carbon steel, titanium, brass, copper, and engineering plastics (POM, PEEK, nylon). Some suppliers also process wood, bamboo, and composite materials depending on tooling configuration.

What is the typical minimum order quantity (MOQ)?

MOQ varies widely: many suppliers accept 1-piece orders for prototypes or samples, while batch production typically starts at 100 pieces. Packaging units (e.g., “1 pack”) may obscure exact quantities—clarify with the supplier before ordering.

How long does it take to receive CNC-machined parts?

Standard lead time ranges from 10 to 20 days after drawing approval. Complex 5-axis machining or additional surface treatments (anodizing, plating) may extend timelines by 5–10 days. Express services are available from select suppliers for urgent needs.

Can suppliers handle full project lifecycle from design to delivery?

Yes, leading suppliers provide turnkey solutions including 3D modeling support, DFM analysis, rapid prototyping, mass production, and final packaging. They often assign dedicated engineers to manage technical communication and ensure design integrity throughout manufacturing.

Are surface treatments included in CNC machining services?

Most suppliers offer secondary finishing options such as anodizing (Type II/III), electroplating, powder coating, sandblasting, brushing, and laser marking. Specify color, thickness, corrosion resistance (e.g., salt spray test duration), and regulatory compliance (RoHS, REACH) requirements during inquiry.