Cnc Machining Meaning

Top sponsor listing

Top sponsor listing

About cnc machining meaning

Where to Find CNC Machining Meaning Suppliers?

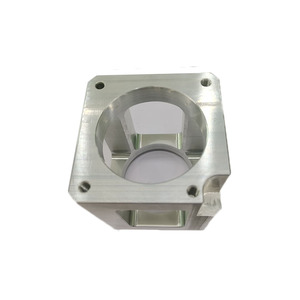

China remains the global epicenter for precision CNC machining services, with Shenzhen and Hangzhou emerging as key manufacturing hubs due to concentrated expertise in metal fabrication and advanced digital manufacturing. These regions host vertically integrated facilities capable of delivering high-precision components across industries such as aerospace, medical devices, automotive, and consumer electronics. The clustering effect enables streamlined access to raw materials, secondary processing (e.g., anodizing, stamping), and rapid prototyping technologies, reducing production cycles by up to 30% compared to decentralized supply chains.

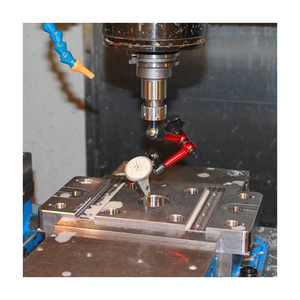

Suppliers in this ecosystem typically operate multi-axis CNC milling and turning centers, supported by in-house design and quality control teams. Average facility sizes range from 1,000 to 5,000+ m², enabling scalability for both low-volume prototypes and medium-batch production runs. Buyers benefit from localized ecosystems where sheet metal fabrication, casting, and assembly services are co-located, facilitating end-to-end part fulfillment within tight tolerances (±0.005 mm standard accuracy). Lead times average 15–25 days for custom orders, with expedited processing available for urgent requests.

How to Choose CNC Machining Meaning Suppliers?

Selecting a reliable partner requires structured evaluation based on technical capability, operational performance, and transactional reliability:

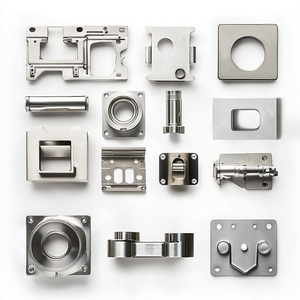

Technical and Production Capabilities

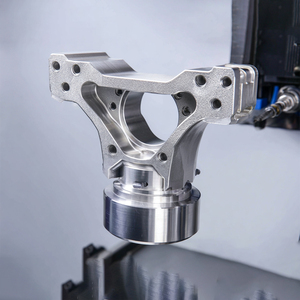

Verify that suppliers possess in-house CNC machining infrastructure, including 3-, 4-, and 5-axis milling machines, lathe turning centers, and EDM/wire-cut capabilities. Prioritize vendors offering full-process control—from CAD/CAM modeling to finishing operations like polishing, anodizing, or passivation. Evidence of dimensional inspection equipment (CMM, optical comparators) indicates adherence to precision standards. Cross-reference listed product volumes (e.g., 475+ machining service listings) as a proxy for operational scale and market validation.

Quality Assurance and Compliance

While formal ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates above 96% and documented response times ≤3 hours suggest mature internal quality management systems. Reorder rates exceeding 50%—as seen with Hangzhou Aoyi Trade Co., Ltd.—indicate customer satisfaction and process reliability. For regulated industries, confirm material traceability, surface finish specifications, and compatibility with industry-specific requirements (e.g., RoHS, REACH).

Customization and Secondary Processing

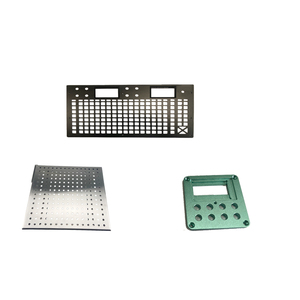

Top-tier suppliers support extensive customization, including:

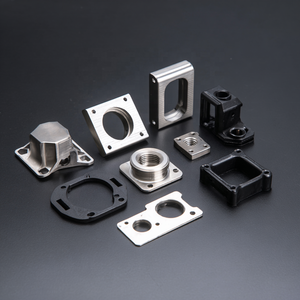

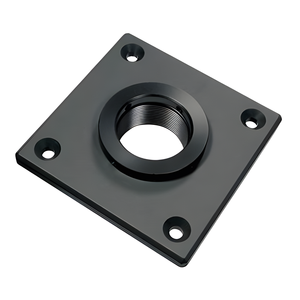

- Material selection: aluminum, stainless steel, brass, titanium, and engineering plastics

- Finishing options: anodizing (color-coded), electroplating, sandblasting, laser engraving, rubber coating

- Design flexibility: acceptance of STEP, DWG, IGES, and 3D scanning files

- Low-volume production: minimum order quantities starting at 1 piece for prototyping

Advanced providers integrate additive manufacturing (SLA, DLP, PolyJet) alongside CNC workflows for hybrid development projects.

Transaction and Risk Mitigation

Assess supplier responsiveness (target ≤3h average reply time) and reorder rate as indicators of service consistency. Use incremental ordering strategies—start with sample batches—to validate quality before scaling. Confirm packaging, labeling, and logistics coordination capabilities for international shipments. Consider online revenue volume (e.g., $180,000+ annual platform turnover) as a proxy for market presence and financial stability.

What Are the Best CNC Machining Meaning Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Scope | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Runze Metal Technology Co., Ltd. | Sheet Metal Fabrication (574) | 96% | ≤3h | 48% | $1.8M+ | Anodization, stamping, die casting, assembly, graphic coating | 1 pc | $0.50–$15.20 |

| Shenzhen VMT Metal Product Co., Ltd. | Machining Services (475) | 100% | ≤2h | 37% | $190K+ | Full CNC milling/turning, precision stainless/aluminum parts | 1 pc | $0.30–$1.00 |

| Hangzhou Aoyi Trade Co., Ltd. | Machining Services (N/A) | 96% | ≤3h | 56% | $180K+ | Micro-machining, 3D scanning, SLA printing, dark chrome/gold coatings | 2 pcs | $0.15–$0.81 |

| LML Metal Product Ltd. | Machining Services (N/A) | 100% | ≤4h | 35% | $90K+ | Anodizing, engraving, heat treatment, 3D scanning, fastener integration | 1 pc | $0.50–$15.20 |

| Shenzhen Huayisheng Precision Manufacturing Co., Ltd. | Machining Services (651) | 60% | ≤1h | 50% | $20K+ | Anodized machining, OEM fabrication, turning/milling | 1 pc | $0.90–$10.00 |

Performance Analysis

Shenzhen VMT and LML Metal demonstrate strong operational discipline with 100% on-time delivery, making them suitable for time-sensitive procurement. Hangzhou Aoyi stands out with a 56% reorder rate—the highest in the dataset—indicating superior customer retention likely driven by advanced surface finishing and micro-machining capabilities. Although Shenzhen Huayisheng offers rapid response times (≤1h), its 60% on-time delivery rate presents a notable risk for scheduled production. Shenzhen Runze leads in revenue volume ($1.8M+), reflecting extensive market engagement and diversified service offerings including full assembly and packaging.

FAQs

What does "CNC machining meaning" refer to in industrial sourcing?

The term refers to suppliers specializing in Computer Numerical Control (CNC) machining processes, including milling, turning, grinding, and drilling, used to produce high-precision metal or plastic components from digital designs. In sourcing contexts, it identifies vendors offering custom machining services rather than finished goods.

What are typical MOQs for CNC machining services?

Minimum order quantities vary: many suppliers accept single-piece orders for prototyping, while others require 2–100 pieces depending on setup complexity. Low-volume production (1–100 pcs) is common, supporting iterative design and testing phases.

How long do CNC machining projects take to fulfill?

Standard lead times range from 10–25 days post-design approval. Rapid-turnaround providers can deliver prototypes in 5–7 days. Additional time should be allocated for shipping, especially for air or sea freight to international destinations.

Can CNC machining suppliers handle complex finishes and coatings?

Yes, leading suppliers offer post-processing services such as Type II/III anodizing, electroplating, powder coating, sandblasting, and laser marking. Some provide color matching (Pantone), mirror polishing, and specialized coatings like TPEE or PEBA for functional enhancements.

How to verify CNC machining supplier capabilities remotely?

Request sample parts with dimensional reports, material certifications, and process documentation. Conduct virtual factory audits via video tour to assess machine conditions, workflow organization, and quality inspection stations. Evaluate responsiveness, file handling proficiency, and technical feedback clarity during initial communications.