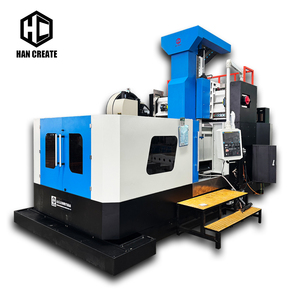

Cnc Machining Machine

Top sponsor listing

Top sponsor listing

About cnc machining machine

Where to Find CNC Machining Machine Suppliers?

China remains the global epicenter for CNC machining machine manufacturing, with key industrial clusters concentrated in Shandong, Shanghai, and Guangdong provinces. Shandong province hosts a dense network of equipment manufacturers specializing in vertical machining centers and CNC lathes, supported by integrated metalworking supply chains that reduce component procurement lead times by up to 30%. Shanghai-based suppliers emphasize precision engineering and export-ready compliance, leveraging advanced metrology systems such as CMM detection and laser cutting verification. Guangdong’s ecosystem focuses on high-speed spindle integration and compact desktop units, catering to electronics and medical device subcontractors requiring micro-part accuracy.

These regional hubs offer vertically integrated production capabilities—from raw material processing to final assembly—enabling rapid prototyping and scalable batch production. Facilities typically maintain in-house design teams, heat treatment lines, and surface finishing operations (e.g., anodizing, passivation, sandblasting), allowing end-to-end control over quality and delivery. Buyers benefit from average cost advantages of 20–35% compared to European or North American suppliers, alongside lead times of 30–45 days for standard configurations. Custom orders with multi-axis integration or hardened tooling typically extend to 60 days.

How to Choose CNC Machining Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Capabilities

Confirm adherence to international quality standards such as ISO 9001. For exports to regulated markets, CE marking is essential for electrical safety and electromagnetic compatibility. Evaluate machine specifications including axis count (3-, 4-, or 5-axis), spindle speed (up to 8,000 RPM in mid-tier models), linear guideway type, and servo motor integration. Suppliers offering customization should provide detailed process documentation covering material selection (aluminum, steel, titanium), tolerance levels (down to ±0.003mm), and post-processing options like hardness testing or Pantone-matched painting.

Production Capacity Verification

Assess infrastructure maturity through objective metrics:

- Minimum factory area exceeding 3,000m² to support dedicated zones for milling, turning, and EDM operations

- In-house R&D teams capable of generating technical drawings, 3D renderings, and prototype validation reports

- Integrated quality control systems including coordinate measuring machines (CMM) and laser alignment tools

Cross-reference declared capabilities with on-time delivery performance (target ≥95%) and reorder rates as indicators of customer satisfaction.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate pre-shipment risk. Prioritize suppliers with verifiable transaction histories, documented response times (ideally ≤2 hours), and transparent dispute resolution practices. Request sample units to validate dimensional accuracy, surface finish quality, and controller functionality (Fanuc, Siemens, or equivalent). Insist on factory inspection protocols before shipment, including dry-run tests and packaging integrity checks.

What Are the Best CNC Machining Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Support | Key Equipment Offerings |

|---|---|---|---|---|---|---|---|---|

| Jinan Hongda Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathe (711), Machining Centre (425) | US $950,000+ | 100% | ≤1h | 30% | Yes | VMC650, XH7124, Fanuc-controlled units |

| Shanghai Yecheng Mechanical And Electrical Co., Ltd. | Shanghai, CN | Machining Services (945) | US $440,000+ | 100% | ≤1h | 28% | Yes | Precision micro parts, deep machining, anodizing |

| Shenzhen Richon Industry Co., Ltd. | Guangdong, CN | Not specified | US $290,000+ | 88% | ≤2h | 15% | Yes | High-speed spindles, XK71 series, VMC650 |

| Shandong Mainland Cnc Equipment Co., Ltd | Shandong, CN | CNC Lathe (497), Manual Mills (324) | US $180,000+ | 100% | ≤3h | 22% | Limited | VMC1370, XK7136, 4-axis VMC640 |

| Jinan Taihe Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathe (152), Machining Centre (130) | Data not available | 100% | ≤1h | No data | Basic | Mini VMC640, GMC1611 gantry, 5-axis desktop |

Performance Analysis

Jinan Hongda stands out with the highest online revenue and robust product diversification across CNC lathes and machining centers, indicating strong market penetration and scalability. Shanghai Yecheng excels in value-added services, offering comprehensive customization including electroplating, stamping, and graphic labeling—ideal for buyers requiring branded or application-specific components. Shenzhen Richon offers competitive pricing (from $4,000/unit) but exhibits lower on-time delivery reliability (88%), suggesting potential fulfillment risks under peak demand. All Shandong-based suppliers demonstrate perfect on-time delivery records, reflecting mature logistics coordination within the regional cluster. Buyers seeking complex multi-process integration should prioritize suppliers with documented CMM detection and laser cutting validation in their workflow.

FAQs

How to verify CNC machining machine supplier reliability?

Validate certifications (ISO, CE) through official registries and request third-party audit summaries. Examine supplier-provided facility videos highlighting CNC cell layouts, quality inspection stations, and inventory management. Analyze transaction patterns, focusing on consistent reorder rates (>25%) and sub-2-hour response times as proxies for operational discipline.

What is the typical MOQ and lead time?

Standard practice is a minimum order quantity of 1 set, suitable for pilot procurement. Lead time averages 30–45 days for off-the-shelf models. Customized machines with non-standard controllers or reinforced boxways may require 50–60 days. Rush orders are occasionally accommodated at +15–20% cost premium.

Do suppliers support customization?

Yes, most suppliers listed offer customization in material selection, dimensional tolerances, surface treatments (anodizing, sandblasting, brushing), and branding (logo engraving, Pantone color matching). Full turnkey solutions—including assembly and packaging design—are available from top-tier providers like Shanghai Yecheng and Jinan Hongda.

Can CNC machining machines be shipped globally?

All major suppliers have export experience and manage international logistics via FOB or CIF terms. Proper crating, moisture protection, and marine insurance are standard. Confirm voltage compatibility (380V/50Hz vs. 480V/60Hz) and controller language settings (English interface availability) prior to shipment.

Is sample testing recommended before bulk ordering?

Strongly advised. Samples allow verification of machining accuracy, noise levels, and software interface usability. Most suppliers charge partial sampling fees, which may be credited toward future orders exceeding two units. Prototype turnaround typically ranges from 15–25 days depending on complexity.