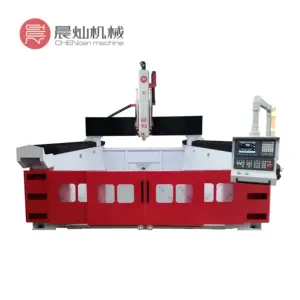

Cnc Router Machining Services For Foam

1/16

1/16

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/10

1/10

1/3

1/3

0

0

1/3

1/3

1/9

1/9

1/3

1/3

1/10

1/10

1/3

1/3

1/3

1/3

1/3

1/3

1/9

1/9

1/3

1/3

1/5

1/5

About cnc router machining services for foam

Where to Find CNC Router Machining Services for Foam Suppliers?

China remains the global epicenter for CNC router machining services tailored to foam processing, with Shandong province emerging as a dominant hub. Industrial clusters in Jinan concentrate specialized expertise in multi-axis CNC systems designed for lightweight materials such as EPS, EPP, and polyurethane foams. These regions benefit from vertically integrated supply chains encompassing precision mechanics, servo motor production, and industrial automation components, enabling cost efficiencies of 20–35% compared to Western manufacturers.

The ecosystem supports rapid prototyping and batch production through co-located component suppliers and technical engineering firms within a 50km radius. This proximity reduces lead times for standard CNC router setups to 30–45 days, while customization cycles remain competitive at 45–60 days. Buyers gain access to scalable manufacturing networks capable of fulfilling both low-volume prototypes and high-volume industrial deployments across aerospace tooling, architectural modeling, and signage sectors.

How to Choose CNC Router Machining Services for Foam Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Technical Capability Verification

Confirm support for 4-axis and 5-axis CNC systems optimized for low-density materials. Key features include vacuum tables for material stabilization, high-speed spindles (12,000–24,000 RPM), and ATC (Automatic Tool Changer) integration. Suppliers should provide documentation on motion control systems (e.g., Syntec, DSP, or NC Studio) and compatibility with CAD/CAM software such as Mastercam, ArtCAM, or Type3.

Production Infrastructure Assessment

Evaluate operational scale using verifiable metrics:

- Facility size exceeding 3,000m² indicating capacity for dedicated foam machining lines

- In-house R&D teams focused on foam-specific toolpath optimization and dust extraction systems

- Integration of CCD cameras, ball screws, and t-slot worktables to enhance cutting precision

Cross-reference these capabilities with on-time delivery performance (target ≥90%) and response time benchmarks (≤2 hours).

Quality & Transaction Assurance

Prioritize suppliers demonstrating compliance with international quality frameworks. While ISO 9001 certification is not universally listed, consistent on-time delivery (100% in leading cases) and documented reorder rates signal operational reliability. Utilize secure transaction mechanisms where available and request sample outputs to verify surface finish accuracy and dimensional tolerance (±0.1mm typical for premium machines).

What Are the Best CNC Router Machining Services for Foam Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Jinan Spower Machinery Technology Co., Ltd. | Shandong, CN | Wood Routers, Industrial Components, Safety Systems | US $180,000+ | 100% | ≤2h | 54% | $9,999–42,000 | Yes (color, spindle type, tool changer, safety packaging) |

| Jinan Owin Cnc Equipment Co., Ltd. | Shandong, CN | Wood Routers (26), Plasma Cutters, Laser Machines | US $10,000+ | 100% | ≤2h | <15% | $2,000–55,000 | Limited (machine size, axis configuration) |

| LUOX INC. | Shandong, CN | Stone Machinery (733), Plastic & Cloth Cutting Machines | Not disclosed | Not available | ≤6h | Not available | $5,000–19,999 | Basic (axis, board type) |

| Jinan Routerstar CNC Machinery Co., Ltd. | Shandong, CN | Wood Routers (153), Wood Lathes, CNC Parts | US $340,000+ | 90% | ≤3h | 22% | $16,500–59,900 | Yes (tool height, lubrication, mist spraying) |

| Jinan Speedy CNC Equipment Co., Ltd. | Shandong, CN | Wood Based Panels Machinery (209), Routers (95) | US $200+ | 100% | ≤1h | <15% | $10,000–60,000 | Yes (ATC, vacuum table, 5-axis integration) |

Performance Analysis

Jinan Spower stands out with the highest reorder rate (54%) and robust customization depth, indicating strong customer retention and engineering flexibility. Jinan Routerstar leads in online revenue ($340,000+), reflecting market trust and export volume, though its 90% on-time delivery suggests moderate fulfillment risk. Jinan Speedy and Jinan Owin achieve perfect delivery records but report lower repeat order activity, potentially signaling transactional rather than relational buyer engagement. LUOX INC., despite extensive product listings, lacks verifiable performance data, presenting higher due diligence requirements. Price diversity spans from entry-level $2,000 models to advanced $60,000 five-axis systems, allowing tiered sourcing strategies based on precision needs and budget constraints.

FAQs

How to verify CNC router foam machining supplier reliability?

Cross-check claimed delivery performance and response times against transaction history where available. Request evidence of past projects involving foam materials, particularly EPS or 3D sculpting applications. Verify presence of core technical staff through facility videos or live demonstrations focusing on machine calibration and tool management systems.

What is the typical lead time for customized CNC routers for foam?

Standard configurations ship within 30–45 days. Customized units with ATC, CCD alignment, or dual-table setups require 45–60 days depending on complexity. Add 10–15 days for international sea freight to major ports.

Do suppliers offer machining services or only equipment sales?

Most suppliers specialize in machine manufacturing rather than contract machining. However, several offer initial trial runs or sample part production to validate machine performance before shipment. Confirm service scope directly during technical consultations.

What are common customization options for foam CNC routers?

Available modifications include spindle power (3kW–9kW), vacuum zone partitioning, automatic lubrication, tool changers (6–12 station ATC), safety enclosures, and software integration. Advanced options like mist cooling and active dust extraction improve longevity when processing fine particulates.

Are there minimum order quantities for CNC router purchases?

All listed suppliers maintain a minimum order quantity of 1 set, facilitating pilot procurement and small-scale adoption. Bulk discounts typically apply for orders exceeding five units, with negotiated logistics support for container shipments.