Computer Control Of Manufacturing Systems

Top sponsor listing

Top sponsor listing

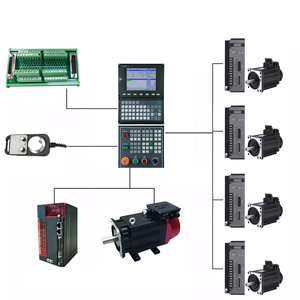

About computer control of manufacturing systems

Where to Find Computer Control of Manufacturing Systems Suppliers?

China remains a dominant force in the production of computer-controlled manufacturing systems, with key supplier clusters concentrated in industrial hubs such as Shenzhen, Hangzhou, and Zhejiang. These regions host vertically integrated supply chains that combine advanced electronics, automation engineering, and mechanical fabrication, enabling end-to-end system development. Shenzhen excels in embedded computing and industrial PC integration, supporting rapid deployment of control units for automated production lines. Meanwhile, Hangzhou and Zhejiang specialize in large-scale chemical and detergent manufacturing systems, where precise computerized process control is critical for batch consistency and operational safety.

The geographic concentration of suppliers facilitates access to specialized component manufacturers, software developers, and testing facilities within compact logistical radii—reducing lead times and enhancing customization agility. Buyers benefit from established ecosystems offering modular system designs, scalable automation solutions, and direct manufacturer pricing. Typical advantages include 20–35% cost savings compared to Western OEMs, lead times averaging 45–60 days for custom turnkey systems, and robust support for both standard and engineered-to-order configurations.

How to Choose Computer Control of Manufacturing Systems Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Expertise and System Integration

Verify suppliers’ capabilities in programmable logic controllers (PLCs), human-machine interfaces (HMIs), SCADA systems, and industrial IoT connectivity. Prioritize vendors with documented experience in closed-loop process control, real-time monitoring, and fault diagnostics. For chemical or food-grade applications, ensure compliance with industry-specific standards such as GMP, ATEX, or IEC 61508 for functional safety.

Production and Engineering Capacity

Assess infrastructure through the following benchmarks:

- Minimum 3,000m² factory area for system assembly and integration

- In-house engineering teams capable of PLC programming and HMI configuration

- Proven track record in delivering turnkey systems (e.g., fully automated powder production lines)

- On-time delivery rate exceeding 95% and response time under 4 hours

Cross-reference product listings with actual project portfolios to validate scalability and system complexity handled.

Quality Assurance and Transaction Security

Require evidence of quality management systems such as ISO 9001 certification. While not all suppliers list formal certifications in public data, consistent on-time delivery (≥96%) and high reorder rates (>25%) serve as proxy indicators of reliability. Utilize secure payment mechanisms and insist on pre-shipment inspection protocols. Request system documentation including wiring diagrams, control logic flowcharts, and user manuals prior to commissioning.

What Are the Best Computer Control of Manufacturing Systems Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Shenzhen Elsky Technology Co., Ltd. | Industrial Computers, Motherboards, Mini PCs, All-in-One Systems | 96% | ≤3h | 27% | US $3,900,000+ | Color, material, size, logo, packaging, graphics |

| Zhejiang Meibao Industrial Technology Co., Ltd. | Detergent Powder Lines, Spray Drying Towers, Mixing Equipment | 100% | ≤17h | - | - | Full system automation and layout customization |

| Hangzhou Asia Chemical Engineering Co., Ltd. | Liquid & Powder Production Plants, Sulphonation Systems | 100% | ≤21h | - | - | Turnkey plant design with integrated control systems |

| Longnan City Brotherholding Protective Equipment Co., Ltd. | CNC Machining Centers, Used Drilling & Milling Machines | 100% | ≤4h | 100% | US $5,000+ | Limited; primarily equipment resale with basic controls |

| Jinan Routerstar CNC Machinery Co., Ltd. | Mini CNC Lathes, Woodworking Automation, Laser Cutters | 92% | ≤2h | 22% | US $340,000+ | Functional modifications for small-scale automation |

Performance Analysis

Suppliers like Zhejiang Meibao and Hangzhou Asia Chemical Engineering demonstrate strong engineering integration, offering fully automated, computer-controlled production lines for detergent and chemical processing—with investment ranges from $30,000 to over $1 million per system. Their 100% on-time delivery records indicate disciplined project execution, though slower response times suggest room for improvement in customer engagement. In contrast, Shenzhen Elsky Technology provides core computing hardware essential for industrial control systems, backed by high online revenue and responsive communication, making it suitable for buyers sourcing embedded control units or IPC-based solutions. Jinan Routerstar caters to niche micro-manufacturing needs with entry-level CNC systems priced between $1,900–$2,000, ideal for prototyping or small workshops. Longnan Brotherholding stands out with a 100% reorder rate, indicating strong post-sale satisfaction despite offering used machinery.

FAQs

How to verify supplier capability for computer-controlled system integration?

Request detailed technical proposals outlining control architecture (PLC brand, I/O count, communication protocols), software interface examples, and validation test procedures. Conduct virtual factory audits to observe system assembly and testing processes.

What is the typical MOQ and lead time for automated manufacturing systems?

Most suppliers require a minimum order of 1 set, with lead times ranging from 45 to 90 days depending on system complexity. Custom-designed plants (e.g., LABSA sulphonation lines) may require up to 120 days for engineering, fabrication, and factory acceptance testing.

Do suppliers offer customization for control software and HMI layouts?

Yes, leading suppliers provide tailored HMI screens, multilingual interfaces, data logging functions, and remote monitoring via Ethernet or 4G modules. Confirm software development included in quotation and ownership of source code.

Are there export controls or logistics considerations for computer-controlled machinery?

Automated industrial systems are generally exportable, but buyers must verify voltage compatibility (380V/50Hz vs. 480V/60Hz), CE or CCC markings if required, and proper crating for sea freight. Suppliers typically offer FOB terms, with CIF options available upon request.

Can buyers request system validation or performance testing before shipment?

Reputable suppliers conduct FAT (Factory Acceptance Testing) with client participation via video call. Buyers should specify test criteria—including uptime trials, alarm response checks, and recipe switching—during contract negotiation.