Computer Hardware Assembly

Top sponsor listing

Top sponsor listing

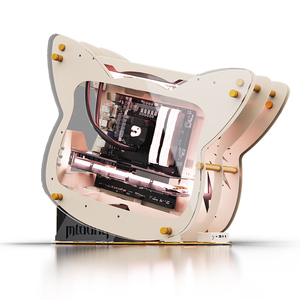

About computer hardware assembly

Where to Find Computer Hardware Assembly Suppliers?

China remains the global epicenter for computer hardware assembly manufacturing, with key industrial hubs concentrated in Guangdong Province—particularly Shenzhen and Dongguan. These regions host vertically integrated ecosystems that combine precision machining, electronics fabrication, and rapid prototyping under one supply chain. Shenzhen’s status as a Tier-1 technology hub enables access to advanced SMT lines, automated PCB assembly facilities, and an extensive network of component distributors, reducing lead times by up to 40% compared to non-specialized regions.

The clustering effect allows suppliers to offer scalable production from prototype batches to high-volume OEM contracts. Facilities typically operate within compact logistics zones where raw materials, sub-component manufacturers, and final assembly plants are located within 30–50 km. This integration supports agile production cycles, with standard order fulfillment averaging 15–25 days for assembled units and 7–14 days for component-only shipments. Buyers benefit from localized sourcing of critical materials such as aluminum alloys, copper heatsinks, zinc-plated steel fasteners, and FR-4 PCB substrates, contributing to 20–30% lower unit costs versus Western-based manufacturers.

How to Choose Computer Hardware Assembly Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Prioritize suppliers with documented expertise in surface-mount technology (SMT), through-hole assembly, and automated optical inspection (AOI). For full-system integrators, confirm in-house capabilities in chassis fabrication, thermal management systems (including water cooling), and cable sleeving. Key indicators include:

- Minimum facility size of 2,000m² for sustained volume output

- Dedicated R&D or engineering teams supporting customization

- In-house testing protocols for signal integrity, power delivery, and thermal performance

- Support for multi-layer PCBs (up to 10+ layers) and HDI configurations

Quality Assurance & Compliance

Verify adherence to international standards such as ISO 9001 for quality management and IPC-A-610 for electronic assembly acceptability. While not all suppliers list RoHS or CE certifications explicitly, these should be contractually required for EU and North American markets. Request test reports for solder joint reliability, EMI/EMC compliance, and burn-in procedures for assembled motherboards or PSUs.

Customization and Scalability

Assess flexibility in material selection, RGB lighting integration, fan configuration, and branding options (e.g., silk printing, custom labels, molded logos). Confirm minimum order quantities (MOQs) align with procurement strategy—many suppliers offer low MOQs (as low as 5–10 pieces) for prototypes or niche builds. Reorder rates above 25% indicate strong customer retention and consistent quality.

Transaction Security & Communication Efficiency

Favor suppliers with response times under 3 hours and on-time delivery rates exceeding 95%. Analyze historical performance metrics: companies with reorder rates above 20% and verifiable online revenue (US $150,000+) demonstrate market credibility. Use secure payment terms with milestone-based releases, especially for custom tooling or large-scale orders.

What Are the Best Computer Hardware Assembly Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Scope | Typical MOQ |

|---|---|---|---|---|---|---|---|---|

| Dongguan Qifeng Electronic Technology Co., Ltd. | Dongguan, CN | Fans & Cooling (1,225); Cases (952); PSU (63) | 90% | ≤3h | 21% | US $1.2M+ | RGB fans, sleeved cables, mesh panels, logo printing, SSD mounting | Varies by product (typically 10–100 pcs) |

| Shenzhen Fute Hardware Company Limited | Shenzhen, CN | Standoffs, Precision Screws, PCB Spacers | 100% | ≤2h | 25% | US $230,000+ | Material (titanium, carbon steel), plating, thread size, packaging | 100 pieces |

| Dongguan City Hui Xuan Hardware Co., Ltd. | Dongguan, CN | Micro-screws, Radiator Springs, CPU/GPU Mounting Hardware | 96% | ≤1h | <15% | US $150,000+ | Size, material, color, labeling, packaging design | 100–1,000 pieces |

| Shenzhen Yachuanglian Technology CO.,Ltd. | Shenzhen, CN | OEM PCB Assembly, PCBA, Circuit Board Integration | 100% | ≤2h | 28% | US $270,000+ | Board layout, component sourcing, firmware integration, labeling | 5–1 piece |

| Shenzhen City Yueda Technology Co., Ltd. | Shenzhen, CN | Multi-layer Motherboards, AI-Grade PCBAs, Rockchip Platforms | 100% | ≤2h | <15% | US $400+ | Layer count, chipset integration, stack-up design, impedance control | 2 pieces |

Performance Analysis

Dongguan Qifeng stands out for breadth of inventory and system-level assembly offerings, particularly in cooling solutions and case customization. Shenzhen Fute and Hui Xuan specialize in high-precision mechanical components essential for stable hardware mounting, with sub-2-hour response times enhancing collaboration efficiency. Yachuanglian and Yueda represent advanced electronics integrators, offering full PCBA services with low MOQs ideal for startups and R&D projects. Notably, Yueda provides AI-capable motherboard assemblies using Rockchip RK3588s architecture, positioning it for edge computing applications. A 100% on-time delivery rate is common among top-tier suppliers, while reorder rates above 25%—as seen with Yachuanglian and Fute—signal robust post-sale satisfaction. For mission-critical builds, prioritize suppliers with proven experience in thermal design, EMI shielding, and long-term reliability testing.

FAQs

How to verify computer hardware assembly supplier reliability?

Cross-check self-reported metrics with transaction history, customer reviews, and verifiable shipment records. Request factory audit reports or video walkthroughs of production lines. Confirm quality control processes such as AOI, X-ray inspection for BGA joints, and environmental stress testing.

What is the typical lead time for custom hardware assembly?

Standard PCB assembly takes 7–14 days; full system integration (case, cooling, cabling, BIOS setup) requires 15–25 days. Prototypes may be delivered in 5–10 days depending on complexity. Add 5–10 days for air freight internationally.

Can suppliers accommodate small-batch or prototype orders?

Yes, most suppliers listed support low MOQs—from 2 pieces for PCBAs to 10–100 units for screws and standoffs. This enables cost-effective prototyping and iterative design validation before scaling to mass production.

Do hardware assembly suppliers offer private labeling and branding?

Yes, customization includes laser engraving, silk screening, colored anodization, RGB lighting profiles, and custom packaging. Lead time increases by 3–7 days if new molds or tooling are required.

How are quality issues resolved post-shipment?

Established suppliers implement corrective action plans (CAPA) for defective batches. Define warranty terms upfront—including return shipping responsibility and replacement timelines. Consider third-party inspection services pre-shipment for orders exceeding 500 units.