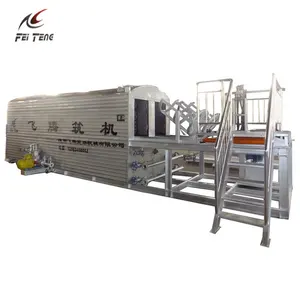

Continuous Manufacturing System

CN

CN

About continuous manufacturing system

Where to Find Continuous Manufacturing System Suppliers?

China remains the central hub for continuous manufacturing system production, with key industrial clusters concentrated in Henan and surrounding regions. These zones host vertically integrated facilities specializing in metallurgy, casting, and extrusion technologies—critical for producing high-efficiency continuous systems used in metal processing. Zhengzhou and Luoyang serve as core manufacturing centers, where proximity to raw material suppliers and steel recycling infrastructure reduces component lead times by up to 25% compared to offshore alternatives.

The ecosystem supports both standardized and engineered-to-order systems, with suppliers offering full-line integration from melting furnaces to rolling mills and casting machines. This co-location of engineering expertise and fabrication capacity enables rapid prototyping and scalable deployment. Buyers benefit from localized supply chains that reduce equipment costs by 20–30%, typical lead times of 45–60 days for custom lines, and access to modular designs adaptable to copper, aluminum, and steel applications.

How to Choose Continuous Manufacturing System Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria focused on technical capability, quality assurance, and transactional reliability:

Technical Compliance & Certifications

Confirm adherence to international quality standards such as ISO 9001. For export markets, CE marking is essential for regulatory compliance in Europe. Request documentation for material traceability, pressure testing, and electrical safety protocols—particularly for systems involving high-temperature furnaces or automated control panels.

Production Capacity Verification

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 5,000m² for large-scale line assembly

- In-house capabilities in CNC machining, welding, and rolling mill integration

- Dedicated R&D teams supporting customization (e.g., billet size, automation level, energy efficiency)

Cross-reference delivery performance (target ≥95%) and response time (≤2 hours) as indicators of operational maturity.

Transaction Security & Quality Control

Utilize secure payment mechanisms such as escrow services until final inspection clearance. Prioritize suppliers with documented QC processes, including pre-shipment testing of casting speed, cooling uniformity, and dimensional accuracy. On-site or virtual audits are recommended to validate production workflows and component sourcing practices.

What Are the Best Continuous Manufacturing System Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Iris Industrial Technology Co., Ltd. | Industrial Furnaces, Metal Casting Machinery, Laser Equipment | 92% | ≤2h | <15% | US $90,000+ | Not specified | $7,999 – $16,180 | 1 set |

| Luoyang Monte Intelligent Technology Co., Ltd. | Copper Extrusion Lines, Vertical Casting Systems | 100% | ≤2h | <15% | US $40,000+ | Material, size, color, logo, packaging | $9,500 – $12,000 | 1 set |

| Luoyang Ruixinsheng Industrial Technology Co., Ltd. | Steel Rebar Lines, Scrap Recycling Systems, Rolling Mills | 100% | ≤1h | 66% | US $230,000+ | Billet sizes, capacity, design, labeling, packaging | $105,000 – $480,000 | 1 set |

| Tangshan Fengrun District Runhao Rolling Machinery Co., Ltd. | Continuous Casting Machines, Steel Rolling Mills, Processing Lines | 100% | ≤4h | - | - | Not specified | $9,000 – $30,000 | 1 set |

| Luoyang Dinghong Electric Technology Co., Ltd. | Metal Casting Lines, Copper Ingot Machines, Electrical Components | 100% | ≤1h | <15% | US $500+ | Not specified | $8,500 – $38,900 | 1 set |

Performance Analysis

Luoyang Ruixinsheng stands out with a 66% reorder rate and extensive customization capabilities, indicating strong customer satisfaction for heavy-duty rebar and recycling systems. Multiple suppliers report 100% on-time delivery, including Luoyang Monte and Tangshan Runhao, reflecting reliable production planning. Luoyang-based manufacturers lead in responsiveness, with two achieving sub-1-hour average reply times. Pricing varies significantly—from entry-level $8,500 units to $480,000 turnkey steel lines—highlighting segmentation between small-scale casters and industrial-grade producers. Buyers seeking integrated solutions should prioritize suppliers with demonstrated experience in full-line automation and third-party verified revenue streams.

FAQs

How to verify continuous manufacturing system supplier reliability?

Audit certification validity through issuing bodies and request test reports for furnace efficiency, casting consistency, and mechanical stress tolerance. Analyze transaction history, response behavior, and customer feedback focusing on after-sales service and technical support responsiveness.

What is the typical lead time for custom continuous manufacturing lines?

Standard configurations ship within 30–45 days. Fully customized systems, especially those integrating automation or special alloy processing, require 60–90 days depending on complexity and component availability.

Do suppliers offer customization for output capacity and materials?

Yes, leading suppliers support adjustments in billet diameter, production speed, and material compatibility (copper, aluminum, steel). Engineering teams can modify furnace power, cooling systems, and downstream processing units based on throughput requirements.

Are samples available before bulk orders?

Full-system sampling is uncommon due to scale, but suppliers may provide subsystem demonstrations or video validation of running lines. Some offer trial runs at their facility for buyer inspection prior to shipment.

What are common payment and logistics terms?

Payment structures typically include 30% deposit and 70% before shipment. FOB terms are standard; CIF is available upon request. Sea freight is optimal for complete lines, with containerized or flat-rack shipping based on machine dimensions.