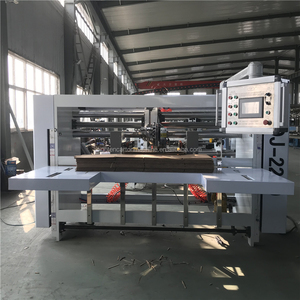

Corrugated Box Machine Semi Automatic

1/3

1/3

1/14

1/14

1/13

1/13

1/26

1/26

1/17

1/17

1/12

1/12

About corrugated box machine semi automatic

Where to Find Corrugated Box Machine Semi Automatic Suppliers?

China remains the global epicenter for semi-automatic corrugated box machine manufacturing, with key industrial clusters concentrated in Hebei and Guangdong provinces. The Cangzhou region in Hebei has emerged as a specialized hub for paper processing and packaging machinery, hosting vertically integrated production networks that support rapid prototyping and large-scale manufacturing. This cluster benefits from proximity to major cardboard raw material suppliers and steel processing facilities, reducing component lead times by up to 25% compared to decentralized regions.

Guangdong-based suppliers, particularly around Shenzhen, focus on compact, energy-efficient models suited for mid-volume packaging operations. These manufacturers leverage advanced CNC machining and modular assembly techniques to offer machines with integrated digital controls and customizable configurations. The regional ecosystem supports agile production cycles, enabling standard order fulfillment within 20–35 days. Buyers gain access to suppliers with established export logistics, compliant with international shipping standards for industrial equipment.

How to Choose Corrugated Box Machine Semi Automatic Suppliers?

Selecting reliable suppliers requires a structured evaluation of technical, operational, and transactional capabilities:

Technical & Production Capabilities

Verify that suppliers operate dedicated manufacturing facilities equipped for precision engineering. Key indicators include in-house fabrication of critical components such as gluing units, pressure rollers, and die-cutting modules. Prioritize suppliers listing specific machinery types—such as folder-gluer systems, slotting machines, or semi-automatic creasing units—as core product lines, indicating focused expertise rather than generalist offerings.

Quality Assurance and Compliance

While explicit certification data is limited in available profiles, assess quality through performance metrics. On-time delivery rates exceeding 95% correlate with disciplined production planning and supply chain control. Suppliers demonstrating ≤2-hour average response times typically maintain active customer service infrastructure, suggesting organizational maturity. For end-market compliance, confirm CE or equivalent safety certifications prior to shipment, especially for European or North American deployments.

Customization and After-Sales Support

Evaluate customization depth beyond basic branding. Advanced suppliers offer adjustments in feed width (e800–2800mm), motor power, glue application systems, and control panel language. Confirm availability of technical documentation, spare parts inventory, and remote troubleshooting support. Suppliers listing “PID control,” “digital control,” or “graphic interface” features demonstrate higher engineering sophistication suitable for process-critical environments.

What Are the Best Corrugated Box Machine Semi Automatic Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Cangzhou Maiken Machinery Equipment Co., Ltd. | Hebei, CN | Folder-Gluer, Die-Cutting, Carton Printing Machinery | US $2,000+ | 100% | ≤2h | <15% | 1 set |

| Cangzhou Zhaoli Import&Export Trade Co., Ltd. | Hebei, CN | Slotting, Gluing, Die-Cutting Machines | US $120,000+ | 100% | ≤2h | <15% | 1 set |

| Shenzhen Crosshill Technology Co., Ltd. | Guangdong, CN | Packaging Line, Digital Control Systems | US $100,000+ | 86% | ≤17h | 21% | 1–2 pieces |

| Wuxi SWF Intelligent Technology Co., Ltd. | Jiangsu, CN | Semi-Automatic Packaging Systems | US $340,000+ | 99% | ≤3h | 19% | 1–2 sets |

| Xuzhou Sanxi Yuan Trading Co., Ltd. | Jiangsu, CN | Not clearly specified | US $50,000+ | 91% | ≤1h | <15% | 2–10 units |

Performance Analysis

Cangzhou-based manufacturers stand out for operational reliability, with both Maiken and Zhaoli achieving 100% on-time delivery—critical for time-sensitive production rollouts. Their specialization in carton processing machinery suggests deeper domain expertise in corrugated board handling, folding accuracy, and adhesive application consistency. Zhaoli offers high-end models priced up to $13,000, indicating capacity for complex machine builds. In contrast, Shenzhen Crosshill provides lower-cost entry-level machines ($399–$1,045 range) but exhibits slower response times, potentially affecting post-sale communication. Wuxi SWF combines strong financial volume (US $340,000+ online revenue) with near-perfect delivery performance, suggesting robust order management despite broader product diversification.

FAQs

What is the typical MOQ for semi-automatic corrugated box machines?

Most specialized suppliers set a minimum order quantity of 1 set, particularly for custom or industrial-grade models. Some generalist traders may require 2–10 units depending on model size and configuration. Bulk pricing typically applies at 5+ sets.

What are common lead times for production and shipping?

Production lead time ranges from 15 to 30 days for standard configurations. Customized machines with digital controls or extended feed widths may require 35–45 days. Sea freight adds 20–40 days depending on destination. Air shipping is rarely cost-effective for full machines due to weight and dimensions.

Do suppliers offer customization options?

Yes, leading suppliers provide customization in blade size, pressure control, glue dosing mechanisms, control panel language, and structural dimensions. High-end models may include PID temperature control, dual motors, or programmable touch-screen interfaces. Confirm design feasibility through technical drawings before order placement.

Are samples available for testing?

Due to the size and complexity of corrugated box machines, physical samples are uncommon. However, suppliers may provide video demonstrations, factory test runs, or component prototypes (e.g., gluing unit operation). For smaller subsystems, sample units may be shipped at partial cost recovery.

How to verify supplier credibility without onsite audits?

Analyze verifiable metrics: on-time delivery rate (>95% ideal), response speed (≤2h preferred), and online transaction volume. Request product-specific certifications (CE, ISO) and third-party inspection reports. Use secure payment methods with milestone releases tied to production stages and pre-shipment inspections.