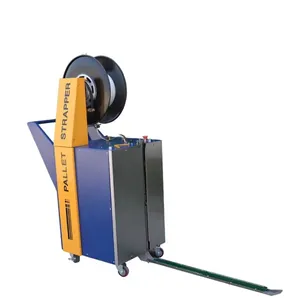

Semi Automatic Box Strapping Machine

1/13

1/13

1/14

1/14

1/18

1/18

1/27

1/27

1/3

1/3

1/11

1/11

1/17

1/17

1/24

1/24

1/6

1/6

1/17

1/17

1/21

1/21

1/15

1/15

About semi automatic box strapping machine

Where to Find Semi Automatic Box Strapping Machine Suppliers?

China remains the global epicenter for semi automatic box strapping machine production, with key manufacturing clusters in Jiangsu and Guangdong provinces. These regions host vertically integrated supply chains that streamline component sourcing—such as motors, sealing heads, and tensioning assemblies—reducing lead times by 20–30% compared to decentralized production models. Jiangsu’s Nantong and Changzhou zones specialize in compact desktop and mid-range industrial strappers, leveraging proximity to steel and electronics suppliers for cost-efficient fabrication.

The concentration of machinery OEMs in these hubs enables economies of scale, particularly for standard PP and PET belt models operating at 0.5–2.0 mm thickness capacity. Facilities typically integrate CNC machining, powder coating, and final assembly under one roof, supporting batch outputs of 100–300 units per month. Buyers benefit from localized logistics networks that ensure domestic delivery within 3–5 days and sea freight readiness for export markets, with average production lead times ranging from 15 to 30 days depending on customization level.

How to Choose Semi Automatic Box Strapping Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international safety and performance benchmarks. While not always explicitly stated, CE marking indicates compliance with EU machinery directives, particularly for electrical components and operator safety. Confirm compatibility with common strap materials (PP, PET, composite) and widths (9–16 mm), as well as minimum sealing temperature ranges (typically 120–180°C). Request test reports for seal strength, tension accuracy (±10%), and cycle durability (minimum 5,000 cycles).

Production Capability Audits

Assess infrastructure maturity through verifiable indicators:

- Minimum factory area exceeding 3,000m² to support dedicated assembly lines

- In-house engineering teams capable of modifying feed mechanisms or motor configurations

- Integration of quality control checkpoints for weld integrity, motor calibration, and thermal sealing consistency

Cross-reference online revenue data and reorder rates as proxies for market validation—suppliers with >30% reorder rates often demonstrate consistent product reliability.

Transaction Safeguards

Prioritize suppliers offering third-party payment protection and post-delivery inspection windows. Analyze response time metrics (≤2 hours is optimal) and on-time delivery records (>95% recommended). For initial orders, request functional samples to evaluate ergonomics, noise levels (<75 dB), and strap feed smoothness before scaling procurement.

What Are the Best Semi Automatic Box Strapping Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Nantong Huabo Technology Co., Ltd. | Wrapping Machines, Sealing Machines, Vacuum Packers | US $20,000+ | 100% | ≤2h | 18% | $199–$1,380 | 1 set |

| Foshan Jiajun Willie Pak Co., Ltd. | Wrapping Machines, Strapping Tools, Dryers | US $30,000+ | 100% | ≤2h | <15% | $149–$1,599 | 1 set |

| Jining Keepway Machinery Company Ltd. | Wrapping Machines, Labeling Systems, Balers | US $590,000+ | 97% | ≤2h | 36% | $255–$990 | 1 set |

| Changzhou Friendpack Equipment Co., Ltd. | Wrapping, Filling, Sealing Machines | US $50,000+ | 94% | ≤2h | 20% | $270–$300 | 1 case |

| Changzhou Friendpack Machinery Co., Ltd. | Packaging Machinery, Custom Automation | US $540,000+ | 96% | ≤3h | 17% | $260–$850 | 1 set |

Performance Analysis

Jining Keepway leads in customer retention with a 36% reorder rate, reflecting strong product consistency and after-sales engagement. Despite slightly lower on-time delivery (97%), its higher revenue volume and competitive pricing ($255–$990 range) suggest robust production scalability. Nantong Huabo and Foshan Jiajun both achieve perfect on-time delivery records, with sub-2-hour response times ideal for urgent sourcing needs. Notably, Changzhou Friendpack Equipment offers uniform pricing at $270/set across multiple SKUs, indicating standardized production optimized for bulk fulfillment. Buyers seeking customization should prioritize Changzhou Friendpack Machinery Co., Ltd., which lists pedal color, pump type, and labeling integration as configurable options.

FAQs

How to verify semi automatic box strapping machine supplier reliability?

Cross-check self-reported metrics such as on-time delivery and reorder rates against transaction history where available. Request evidence of quality management systems—while ISO 9001 certification is not explicitly listed, consistent pricing and multi-product packaging expertise suggest process standardization. Evaluate responsiveness and technical clarity during pre-sales inquiries as indicators of service quality.

What is the typical sampling timeline?

Standard sample production takes 7–14 days, with air freight adding 5–10 days for international delivery. Suppliers may offer expedited 5-day production for an additional fee. Functional testing should include at least 100 strap cycles to assess sealing reliability and motor endurance.

Can suppliers ship globally?

Yes, all listed suppliers have export experience, evidenced by U.S. dollar-denominated pricing and international platform presence. Confirm Incoterm preferences (FOB vs. CIF) and ensure packaging meets export standards for mechanical goods. Sea freight is recommended for orders exceeding 10 units to optimize cost-per-unit logistics.

Do manufacturers provide free samples?

Free samples are uncommon for industrial equipment. Most suppliers charge full or partial sample fees, which may be credited toward future bulk orders (typically 5+ units). Expect sample costs between $250–$500, reflective of unit production expenses.

How to initiate customization requests?

Submit detailed specifications including desired strap width (9/12/16 mm), motor voltage (110V/220V/380V), sealing method (friction/high-frequency), and optional features like digital tension displays or dual-motor drives. Suppliers with customization tags can typically deliver prototypes within 2–3 weeks and provide technical drawings upon request.