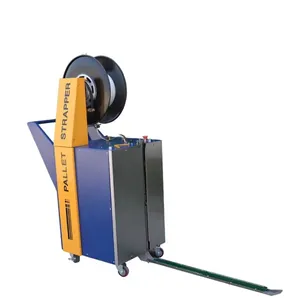

Pp Box Strapping Machine

About pp box strapping machine

Where to Find PP Box Strapping Machine Suppliers?

China remains the global epicenter for PP box strapping machine manufacturing, with key production hubs concentrated in Shandong and Henan provinces. These regions host vertically integrated supply chains that streamline component sourcing—from motor assemblies to polypropylene (PP) feeding systems—reducing production lead times by 20–30% compared to non-specialized markets. Jining and Qingdao in Shandong are recognized for automated packaging line integration, while Henan’s machinery corridor supports high-volume output of semi-automatic and desktop models at competitive ex-factory pricing.

The industrial clusters benefit from localized access to steel fabrication, electrical controls, and polymer processing equipment, enabling rapid prototyping and scalable order fulfillment. Facilities typically operate within compact ecosystems where design, assembly, testing, and logistics services are co-located, allowing standard orders to be processed within 15–30 days. Buyers gain cost efficiencies averaging 25% over Western or Southeast Asian alternatives, particularly for fully automatic systems handling carton sealing speeds up to 30 boxes per minute.

How to Choose PP Box Strapping Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international safety and performance standards. CE marking is essential for EU market entry, confirming compliance with Machinery Directive 2006/42/EC. For North American operations, ensure machines meet applicable electrical and mechanical safety codes. Request documentation on motor insulation class (typically Class F), strap tension accuracy (±5%), and cycle durability tests (minimum 50,000 cycles).

Production Capability Assessment

Evaluate infrastructure maturity through objective metrics:

- Facility size exceeding 3,000m² indicating capacity for batch production

- In-house engineering teams supporting customizations (e.g., conveyor integration, dual-motor drives)

- Core competencies in wrapping machines (100+ listings) and multi-function packaging systems

- On-time delivery rate ≥97% as a proxy for supply chain reliability

Cross-reference product catalogs with actual shipment data; suppliers generating over US $200,000 in annual online revenue demonstrate consistent market demand and post-sale support capability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align payment milestones with delivery and inspection. Prioritize suppliers offering sample units for performance validation under real-world conditions. Analyze reorder rates—those exceeding 30% often reflect strong customer satisfaction and after-sales service quality. Response time under 2 hours indicates dedicated sales engineering support, critical during technical negotiations.

What Are the Best PP Box Strapping Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jining Keepway Machinery Company Ltd. | Shandong, CN | Wrapping Machines (794) | US $600,000+ | 97% | ≤2h | 34% | $255–$1,050 | 1 set |

| Ausim Automation Technology (Shanghai) Co., Ltd. | Shanghai, CN | Multi-Function Packaging Machines (242) | US $300,000+ | 100% | ≤2h | <15% | $800–$1,800 | 1 set |

| Qingdao Youchuang Packaging Equipment Co., Ltd. | Shandong, CN | Wrapping Machines (558) | US $6,000+ | 100% | ≤2h | <15% | $260–$3,800 | 1 set |

| Xinxiang Yongsheng Packaging Materials Technology Co., Ltd. | Henan, CN | Not specified | US $230,000+ | 100% | ≤1h | 16% | $465.90–$1,799 | 1–5 sets |

| Henan Vinica Machinery Co., Ltd. | Henan, CN | Wrapping Machines (263) | US $120,000+ | 95% | ≤4h | <15% | $169.10–$260 | 1 set |

Performance Analysis

Jining Keepway stands out with the highest reorder rate (34%) and broadest product range, suggesting reliable performance and customer retention. Despite lower reported revenue, Qingdao Youchuang offers premium fully automatic models reaching $3,800/unit, indicating specialization in high-speed industrial applications. Ausim Automation maintains a uniform $1,800 price point across its automatic lines, reflecting focus on standardized, high-throughput solutions. Henan-based Vinica provides the most cost-effective entry-level semi-automatic machines ($169.10), ideal for small-scale operations prioritizing upfront cost savings. Suppliers in Shandong dominate in volume-oriented capabilities, while Henan firms excel in responsiveness and lean-order flexibility.

FAQs

What certifications should PP box strapping machines have?

CE certification is mandatory for export to Europe, ensuring compliance with safety, health, and environmental protection standards. ISO 9001:2015 indicates a robust quality management system. Optional but valuable are RoHS declarations for electronic components, especially when shipping to regulated markets.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 set, facilitating pilot procurement. Lead times average 15–25 days for standard configurations. Custom builds involving conveyor integration or voltage modifications may extend to 35 days. Air freight adds 5–7 days globally; sea freight ranges from 20–40 days depending on destination port.

Can suppliers customize strapping machines for specific box sizes?

Yes, reputable manufacturers offer dimensional adaptability, typically supporting box heights from 60mm to 500mm. Customization includes adjustable side seals, variable strap spacing (5–15mm), and compatibility with 10–16mm wide PP belts. Engineering teams can provide CAD drawings within 48 hours upon receipt of technical specifications.

Do suppliers provide installation and training support?

While not standard, many offer remote setup guidance via video call. Some include instructional manuals in English with wiring diagrams and troubleshooting protocols. For large-volume buyers, on-site technician deployment may be negotiated at additional cost.

Are spare parts and after-sales service available?

Leading suppliers stock critical wear components—sealing jaws, drive belts, and feed rollers—with replacement kits typically shipped within 72 hours. Reorder rates above 30% suggest sustained customer engagement and accessible technical support. Confirm warranty terms (commonly 12 months) and availability of local distributors before finalizing contracts.