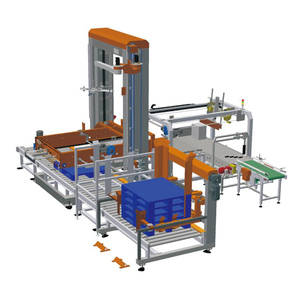

Box Strapping Machine Automatic

Top sponsor listing

Top sponsor listing

1/15

1/15

1/14

1/14

1/17

1/17

1/11

1/11

1/17

1/17

1/3

1/3

1/22

1/22

1/16

1/16

1/3

1/3

About box strapping machine automatic

Where to Find Box Strapping Machine Automatic Suppliers?

China remains the global epicenter for automatic box strapping machine manufacturing, with key production clusters in Shandong, Guangdong, and Zhejiang provinces. These regions host vertically integrated supply chains that streamline component sourcing—such as motors, sealing heads, and conveyor systems—reducing assembly lead times by 20–30% compared to decentralized production models. Shandong-based manufacturers leverage proximity to Qingdao Port, one of China’s busiest export hubs, enabling faster container dispatches and lower freight premiums for trans-Pacific and EU-bound shipments.

The industrial ecosystems support both standardized and engineered-to-order solutions, with many suppliers operating end-to-end facilities encompassing CNC machining, robotic welding, and final-line testing. This integration allows typical lead times of 15–30 days for standard configurations, while custom builds are fulfilled within 30–45 days. Buyers benefit from competitive pricing due to localized material access (PP, PET, and composite straps) and labor efficiency, with average unit costs 25–40% below those of North American or European producers.

How to Choose Box Strapping Machine Automatic Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international safety and performance standards, particularly CE marking for EU market access. Verify inclusion of overload protection, emergency stop mechanisms, and electrical safety compliance (e.g., IEC 60204). Request test reports on cycle durability (minimum 10,000 cycles recommended) and tension consistency (±5% tolerance).

Production Capability Audits

Assess infrastructure maturity through verifiable metrics:

- Facility size exceeding 3,000m² indicating volume capacity

- In-house engineering teams capable of CAD layout design and PLC programming

- Integration of automated testing stations for pre-shipment validation

Cross-reference online revenue indicators and on-time delivery rates (target ≥98%) to assess reliability and order management proficiency.

Customization & Integration Readiness

For line-integrated deployments, confirm supplier experience with pallet dispensers, labeling systems, and robotic arms. Evaluate customization depth—leading suppliers offer adjustments in strapping height (range: 60–1,200mm), conveyor width, strap tension (20–80kgf), and compatibility with multiple case types (RSC, H-top, tray packs).

Transaction Safeguards

Prioritize suppliers with documented quality control processes and responsive communication (response time ≤2 hours). Utilize secure payment structures where possible, ensuring post-delivery inspection rights. Pre-shipment verification should include functional testing under simulated load conditions and review of user manuals in target languages.

What Are the Best Box Strapping Machine Automatic Suppliers?

| Company Name | Type | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Custom Manufacturer | Packaging Line, Wrapping Machines, Conveyors, Sealing Machines | US $1,200,000+ | 100% | ≤2h | 18% | Material size, color, logo, layout, robotic arm integration |

| Jining Keepway Machinery Company Ltd. | Multispecialty Supplier | Wrapping Machines, Labeling Systems, Multi-Function Packaging | US $610,000+ | 97% | ≤2h | 36% | Limited customization; focus on standard automation |

| Qingdao Goldtec Machinery Co., Ltd. | Multispecialty Supplier | Automatic Strappers, Carton Case Equipment, Parcel Strapping | US $290,000+ | 100% | ≤1h | 42% | Color, material size, language interface, label positioning |

| Wenzhou Aimesk Intelligent Equipment Co., Ltd. | Multispecialty Supplier | Intelligent Strapping Systems, Full-Automatic Corrugated Carton Lines | US $320,000+ | 99% | ≤2h | <15% | Logo, packaging label, material specifications |

| Foshan Jiajun Willie Pak Co., Ltd. | Multispecialty Supplier | High-Table Strapping, Metal Roof Sheet Packers, Inline Auto Press | US $70,000+ | 98% | ≤2h | <15% | Roll size, battery options, welding parameters, model variants |

Performance Analysis

Qingdao Ausense stands out for high-volume capability and extensive customization, supported by robust logistics performance and seven-figure annual output. Jining Keepway demonstrates strong customer retention (36% reorder rate), suggesting consistent product reliability and service follow-up. Qingdao Goldtec excels in responsiveness (≤1h average reply) and perfect on-time fulfillment, with a 42% reorder rate indicating high client satisfaction despite mid-tier revenue scale. Wenzhou Aimesk offers competitive entry-level automation at sub-$800 price points, suitable for SMEs prioritizing cost efficiency over deep integration. Foshan Jiajun targets niche applications such as metal sheet bundling, evidenced by specialized product designs and battery-powered mobility options.

FAQs

How to verify box strapping machine supplier reliability?

Validate certifications (CE, ISO 9001) through official registries and request factory audit reports. Examine transaction history for consistent on-time delivery (>98%) and analyze customer feedback for mentions of after-sales support, spare parts availability, and software/firmware updates.

What is the typical MOQ and lead time?

Most suppliers offer MOQs of 1 set, facilitating sample trials. Standard lead time ranges from 15–25 days for off-the-shelf units; customized systems require 30–45 days depending on complexity and integration requirements.

Do suppliers support global shipping and customs clearance?

Yes, experienced exporters provide FOB, CIF, and DAP terms with documentation compliant with destination regulations. Confirm inclusion of packing lists, commercial invoices, and CE/ETL certificates to avoid import delays.

Are free samples available?

Full machine samples are typically not offered free due to size and cost. However, some suppliers may provide discounted pilot units or video demonstrations of live operation. Sample fees are often credited toward bulk orders exceeding five units.

How to initiate a customization request?

Submit detailed specifications including box dimensions (L×W×H), required strapping pattern (I-type, H-type, X-type), strap material (PP/PET), tension settings, power supply (110V/220V/380V), and integration needs (PLC interface, sensor inputs). Leading suppliers respond with CAD layouts and technical proposals within 72 hours.