Creasing Machine Automatic Distributor

About creasing machine automatic distributor

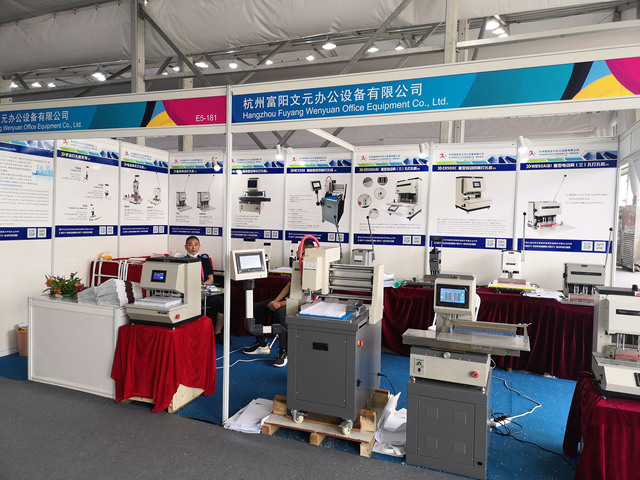

Where to Find Creasing Machine Automatic Distributor Suppliers?

China remains the global epicenter for automatic creasing machine manufacturing, with key supplier clusters concentrated in Shandong, Hebei, and Zhejiang provinces. Shandong-based producers, such as those in Jinan and Yiwu, specialize in mid-to-high-end digital feeding systems and fully automatic models, leveraging proximity to steel and casting iron supply chains that reduce material costs by 15–20%. Cangzhou in Hebei has emerged as a hub for industrial-grade flatbed die-cutting and creasing integration units, offering scalable production lines suited for carton and packaging manufacturers.

These regional ecosystems support vertically integrated operations—from hydraulic presser rack fabrication to CNC-machined guide rail assembly—enabling rapid prototyping and volume output. Suppliers typically maintain in-house R&D teams focused on precision paper feeding, safety feature integration, and multi-language control panels. Buyers benefit from localized component sourcing, with average lead times ranging from 25–45 days for standard configurations. The presence of mature logistics networks ensures efficient export handling, particularly for FOB terms from Qingdao or Tianjin ports.

How to Choose Creasing Machine Automatic Distributor Suppliers?

Procurement decisions should be guided by structured evaluation criteria to mitigate risk and ensure technical compatibility:

Technical Compliance & Quality Assurance

Verify adherence to international standards such as CE marking for electrical and mechanical safety, especially for equipment destined for EU or North American markets. While ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates (≥97%) and documented customization capabilities suggest established quality management systems. Request test reports for critical subsystems including automatic suction feeders, folding position accuracy, and die-cutting pressure calibration.

Production Capacity Verification

Assess operational scale through measurable indicators:

- Facility size supporting batch production (inferred from online revenue exceeding US $470,000)

- In-house engineering capacity for custom modifications (e.g., dual-guide alignment, air-suction feeding, plug-type presser systems)

- Material processing expertise in casting iron frames, precision rails, and hydraulic drive units

Cross-reference response time metrics (≤3 hours for top-tier suppliers) with reorder rates to evaluate service reliability and post-sale support effectiveness.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services where release of funds is tied to equipment performance verification. Prioritize suppliers with transparent transaction histories, including verifiable order volumes and dispute resolution records. Pre-shipment inspection protocols are recommended, particularly for high-value automated systems priced above $50,000.

What Are the Best Creasing Machine Automatic Distributor Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shandong Lukes Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | US $270,000+ | 100% | ≤3h | 15% | $420–1,037 | 1 set/piece |

| Cangzhou Lighten Import & Export Trading Co., Ltd. | Hebei, CN | Multispecialty Supplier | US $120,000+ | 100% | ≤3h | 55% | $19,000–99,999 | 1 set |

| Yiwu Jeta International Trading Co,. Ltd. | Zhejiang, CN | Multispecialty Supplier | US $220,000+ | 100% | ≤4h | <15% | $3,000–120,000 | 1 set |

| Sino Jiguo Machinery Co., Ltd. | Shanghai, CN | Multispecialty Supplier | US $470,000+ | 100% | ≤3h | <15% | $55,714–92,570 | 1 set |

| Jinan Cmall International Trading Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $110,000+ | 97% | ≤5h | 32% | $3,330–8,300 | 1 set |

Performance Analysis

Sino Jiguo Machinery leads in sales volume (US $470,000+), indicating strong market penetration in high-end automatic flatbed systems, despite a low reorder rate suggesting room for improvement in customer retention. Cangzhou Lighten stands out with a 55% reorder rate—signaling high buyer satisfaction—and offers a broad range from semi-automatic to fully integrated machines. Shandong Lukes provides cost-effective entry-level digital creasing solutions starting under $450, ideal for small-scale packaging operations requiring basic automation. Suppliers like Yiwu Jeta and Sino Jiguo focus on premium industrial models exceeding $60,000, targeting enterprises needing CE-compliant, high-precision perforation and folding capabilities. Response efficiency is generally strong across all five, with four achieving sub-4-hour average reply times.

FAQs

How to verify creasing machine supplier reliability?

Evaluate on-time delivery performance (target ≥97%), review customization logs for technical flexibility, and request documentation on component sourcing (e.g., hydraulic systems, digital controllers). Conduct virtual factory audits to confirm in-house production versus dropshipping practices.

What is the typical lead time for automatic creasing machines?

Standard units ship within 20–35 days after order confirmation. Customized configurations involving specialized feeding mechanisms or bilingual interfaces may require 45–60 days, depending on complexity.

Do suppliers support global shipping and customs compliance?

Yes, most suppliers have export experience and can provide CE-marked machinery compliant with European safety directives. Confirm Incoterms (FOB/CIF), packaging specifications, and destination-specific import requirements prior to order placement.

Is customization available for automatic creasing machines?

All listed suppliers offer customization options, including color coding, logo branding, material size adjustments, language selection, safety features, and integration with existing production lines. Technical drawings and system specifications must be submitted for engineering review before production.

What are common minimum order quantities (MOQ)?

MOQ is typically 1 set across all suppliers, facilitating trial purchases and small-batch procurement. This low barrier supports testing and integration into existing workflows without large capital commitment.