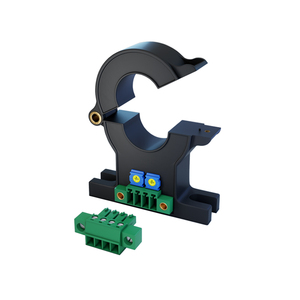

Current Sensor

Top sponsor listing

Top sponsor listing

1/10

1/10

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/14

1/14

1/37

1/37

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/63

1/63

1/16

1/16

1/3

1/3

1/3

1/3

0

0

CN

CN

1/63

1/63

About current sensor

Where to Find Current Sensor Suppliers?

China's current sensor manufacturing sector is concentrated in industrial hubs such as Nanjing and Shenzhen, where specialized electronics clusters support high-precision component production. These regions host vertically integrated supply chains encompassing magnetic core fabrication, Hall-effect IC integration, and signal conditioning circuitry assembly. Proximity to semiconductor suppliers and metrology laboratories enables tight tolerance control (±0.5% to ±2%) across AC/DC transducer lines.

The ecosystem supports both mass production and low-volume customization, with facilities averaging 3–6 month product development cycles for modified sensing ranges or packaging formats. Buyers benefit from localized testing infrastructure—many suppliers maintain in-house calibration benches traceable to national standards—reducing validation lead times by up to 40%. Typical advantages include MOQs as low as 1–3 pieces for evaluation units, scalable output (monthly capacities reaching 50,000+ units per line), and cost efficiencies driven by domestic material sourcing.

How to Choose Current Sensor Suppliers?

Effective supplier selection requires verification across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international standards including IEC 60044-8 (instrument transformers) and RoHS/REACH for hazardous substances. For industrial automation or energy metering applications, demand evidence of EMC immunity (IEC 61000-4 series) and thermal stability testing (-40°C to +85°C operating range). Review datasheets for key parameters: measurement accuracy (typically ±1% for mid-tier models), bandwidth (up to 100kHz for high-speed control systems), and isolation voltage (≥2.5kVAC).

Production Capability Audits

Assess infrastructure maturity through objective indicators:

- On-time delivery performance exceeding 95%

- In-house testing protocols covering linearity, hysteresis, and long-term drift

- Customization capacity for split-core designs, DIN rail mounting, analog (4–20mA/0–5V) or digital (I²C/SPI) outputs

Cross-reference response time metrics (≤2 hours preferred) with reorder rates to gauge service consistency.

Transaction Safeguards

Prioritize suppliers with documented quality management systems and transparent revenue reporting. Utilize secure payment mechanisms that align disbursement with shipment milestones. Conduct sample benchmarking against reference devices before scaling orders—verify zero-point stability and temperature coefficient under load conditions matching end-use environments.

What Are the Best Current Sensor Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Nanjing Chieful Science & Technology Co., Ltd. | Current Sensors, Magnetic Sensors, Other Sensors | $600+ | 100% | <15% | ≤1h | Color, material, size, logo, packaging, graphic | 1 pc | $7–$30 |

| Nanjing Qineng Electronic Technology Co., Ltd. | Hall-Effect Sensors, DC/AC Transducers | $30,000+ | 95% | <15% | ≤2h | Material, size, DIN rail, cable length, logo | 1 pc | $9.50–$11 |

| Nanjing Up Electronic Technology Co., Ltd. | Split-Core Sensors, AC/DC Transmitters | $190,000+ | 98% | 23% | ≤2h | Limited customization reported | 3 pcs | $7–$10 |

| Guangzhou Logoele Electronic Technology Co., Ltd. | High-Accuracy Transducers, Multi-Function Controllers | $70,000+ | 85% | <15% | ≤4h | Application-specific configurations available | 1 pc | $18.50–$30.70 |

| Shenzhen Jinhuigu Technology Development Co., Ltd. | LEM-Compatible Modules, Honeywell-Based Sensors | $120,000+ | 100% | 17% | ≤2h | Output type, connector, shielding options | 1 pc | $16–$60 |

Performance Analysis

Nanjing-based suppliers dominate responsiveness, with three companies achieving sub-2-hour average reply times and on-time delivery rates between 95–100%. Nanjing Qineng and Nanjing Up demonstrate strong balance between volume capability and reliability, supported by multi-year transaction histories and diversified product portfolios. Shenzhen Jinhuigu stands out for handling premium-tier components compatible with LEM and Honeywell specifications, albeit at higher price points. While Nanjing Chieful offers broad customization, its lower online revenue suggests niche-scale operations suitable for prototyping rather than large deployments. Guangzhou Logoele provides high-accuracy solutions but lags in delivery consistency (85%), indicating potential fulfillment risks under peak demand.

FAQs

How to verify current sensor supplier reliability?

Validate certifications through official registries and request test reports for insulation resistance, dielectric strength, and offset drift. Analyze customer feedback focusing on real-world accuracy retention over time. Confirm whether calibration certificates are provided per unit or batch.

What is the typical sampling timeline?

Standard samples ship within 7–14 days. Customized variants requiring PCB redesign or housing modifications take 3–5 weeks. Air freight adds 5–8 business days for international delivery.

Can suppliers accommodate small-batch orders?

Yes, most suppliers listed accept orders as low as 1–3 units. However, unit costs decrease significantly at volumes above 500 pieces due to fixed programming and setup charges.

Do manufacturers provide free samples?

Free samples are uncommon for calibrated sensors. Some suppliers offer sample units at 50–70% discount, redeemable against future bulk orders exceeding $1,000.

How to initiate customization requests?

Submit detailed requirements including current range (e.g., 0–50A DC), output signal type, power supply voltage, mechanical footprint constraints, and environmental rating (IP65, etc.). Reputable partners will return schematic proposals and dimensional drawings within 72 hours.