Custom Cnc Machining China

Top sponsor listing

Top sponsor listing

CN

CN

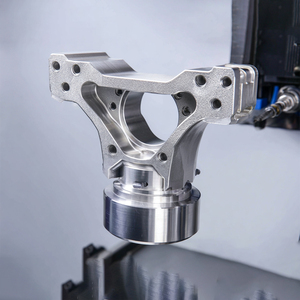

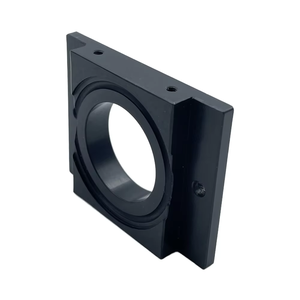

About custom cnc machining china

Where to Find Custom CNC Machining Suppliers in China?

China remains the global epicenter for custom CNC machining services, with high-density industrial clusters concentrated in Guangdong Province—particularly in Dongguan and Shenzhen. These regions host vertically integrated manufacturing ecosystems that combine advanced machining infrastructure, skilled technical labor, and proximity to raw material suppliers. Over 70% of precision hardware manufacturers in this zone operate multi-axis CNC lathes and milling centers, enabling tight-tolerance production (±0.005mm) across aluminum, stainless steel, brass, and engineering plastics.

The region’s supply chain maturity supports rapid prototyping and low-to-high volume production, with average lead times ranging from 7–14 days for initial samples and 15–25 days for bulk orders. Localized sourcing of tooling, fixtures, and secondary processing services (e.g., anodizing, plating, laser engraving) reduces overhead by 18–25% compared to offshore alternatives. Buyers benefit from flexible MOQs—from single-piece prototypes to runs exceeding 10,000 units—supported by digital quoting systems and automated workflow tracking.

How to Choose a Reliable Custom CNC Machining Supplier?

Effective supplier selection requires systematic evaluation across three core dimensions:

Technical & Production Capability

Confirm access to full-spectrum CNC technologies: 3-axis, 4-axis, and 5-axis machining; turning and milling combo centers; micro-machining for components under 5mm diameter. Prioritize suppliers with documented in-house capabilities in sheet metal fabrication, casting integration, and mold-making if project scope extends beyond machining alone. Minimum facility size should exceed 2,000m² for scalable output, supported by dedicated quality inspection zones equipped with CMM (Coordinate Measuring Machine), optical comparators, and surface roughness testers.

Quality Assurance Protocols

ISO 9001 certification is a baseline requirement for process control. For medical, aerospace, or automotive applications, verify adherence to AS9100, IATF 16949, or ISO 13485 standards. Request evidence of incoming material traceability (e.g., mill test reports), first-article inspection (FAI) reports, and statistical process control (SPC) data. Reorder rates above 25% and on-time delivery performance exceeding 95% are strong indicators of operational consistency.

Customization & Communication Efficiency

Assess customization depth: ability to modify material grade, geometric complexity, surface finish (e.g., bead blasting, anodizing type II/III), labeling, and packaging configurations per client drawings or 3D models. Response time under 3 hours and multilingual engineering support enhance collaboration efficiency. Suppliers offering real-time production updates via video reporting or cloud-based dashboards provide greater transparency during order fulfillment.

What Are the Leading Custom CNC Machining Suppliers in China?

| Company Name | Location | Verified Type | Main Services | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Huizhou Jiyan Hardware Co., Ltd. | Huizhou, CN | Custom Manufacturer | Machining Services, Shafts, Sheet Metal, Casting, Moulds | US $40,000+ | 100% | ≤2h | 16% | Material, size, logo, packaging, label, graphic, dimensions |

| Dongguan Xingyao Precision Hardware Co., Ltd. | Dongguan, CN | - | Machining Services | US $7,000+ | 100% | ≤3h | 100% | Drawing- or sample-based customization |

| Dongguan Senyuan Hardware Co., Ltd. | Dongguan, CN | - | Machining Services | US $180,000+ | 100% | ≤1h | 27% | High-precision, micro, large-scale CNC options |

| Dongguan Formal Precision Metal Parts Co., Ltd. | Dongguan, CN | Multispecialty Supplier | 5-axis milling, forging, CMM inspection, turning | US $120,000+ | 87% | ≤5h | 29% | Color, shape, precision, packaging, heat transfer |

| Shenzhen Smart Mold Technology Limited | Shenzhen, CN | Multispecialty Supplier | Precision shafts, mini CNC parts, EVA packaging | US $920,000+ | 97% | ≤2h | 50% | Material, size, logo, packaging, color, graphic |

Performance Analysis

Dongguan Xingyao stands out with a 100% reorder rate, indicating exceptional customer satisfaction despite moderate online revenue, likely due to niche specialization and responsive service. Shenzhen Smart Mold leads in transaction volume (US $920,000+), combining high repeatability (50% reorder) with sub-2-hour response times. Huizhou Jiyan and Dongguan Senyuan both achieve perfect on-time delivery records, suggesting robust production planning. While Dongguan Formal shows slightly lower delivery reliability (87%), its broad customization range—including 5-axis milling and CMM validation—makes it suitable for technically complex projects. Speed-focused buyers will prioritize Senyao (≤1h response) and Jiyan (≤2h).

FAQs

What materials are commonly used in Chinese CNC machining services?

Standard offerings include aluminum alloys (6061, 7075), stainless steel (303, 304, 316), carbon steel, brass (C3604), titanium, and engineering plastics (POM, PEEK, Nylon). Material availability is typically verified through mill certificates and batch traceability systems.

What is the typical minimum order quantity (MOQ)?

MOQ varies by supplier and part complexity. Many offer prototype services with MOQ of 1–5 pieces. High-volume pricing tiers activate at 100–1,000 units. Some suppliers waive setup fees for orders exceeding 500 units.

How long does custom CNC machining take from design to delivery?

Sample lead time averages 7–10 days after drawing approval. Bulk production follows in 12–20 days depending on order size. Surface treatments like anodizing or passivation may add 2–4 days. Air freight adds 5–7 days globally; sea freight takes 20–35 days depending on destination.

Do suppliers support international quality standards?

Leading providers comply with ISO 9001 and can generate FAI, PPAP, and SPC documentation. CE, RoHS, and REACH compliance is available upon request for EU-bound components. Third-party inspection (e.g., SGS, BV) can be arranged pre-shipment.

Can I request product samples before placing a full order?

Yes, most suppliers offer paid sampling, with costs often credited toward future orders. Sample pricing ranges from $0.17 to $8.24 per unit depending on geometry and material. Suppliers with higher online revenue (e.g., Shenzhen Smart Mold) typically have faster sample turnaround (under 7 days).