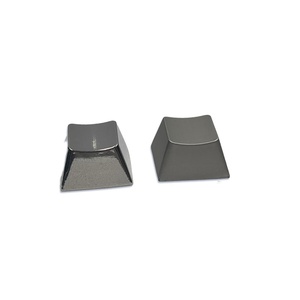

Custom Keycaps Maker

CN

CN

About custom keycaps maker

Where to Find Custom Keycaps Maker Suppliers?

China is the central hub for custom keycap manufacturing, with production clusters concentrated in Guangdong and Jiangsu provinces. Dongguan and Shenzhen in Guangdong are leading centers due to their advanced mold-making infrastructure and proximity to electronics supply chains, enabling rapid prototyping and high-volume output. Nanjing in Jiangsu offers competitive advantages through integrated logistics networks and a skilled labor force specializing in precision plastic components.

These industrial zones support vertically aligned production ecosystems—spanning CNC machining, injection molding, dye-sublimation printing, and packaging—allowing suppliers to deliver end-to-end customization services. Manufacturers benefit from localized access to raw materials like PBT (polybutylene terephthalate) and ABS (acrylonitrile butadiene styrene), reducing material lead times by 20–30%. Buyers typically experience MOQs ranging from 1 piece for sample orders to 50+ sets for bulk production, with standard lead times of 15–25 days post-approval of design files.

How to Choose Custom Keycaps Maker Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Material & Process Expertise

Prioritize manufacturers with proven capabilities in PBT double-shot molding or dye-sublimation techniques, as these ensure long-term durability and colorfast legends. Confirm use of high-flow, UV-resistant resins to prevent yellowing under prolonged exposure. Suppliers offering CNC-machined brass or metal keycaps should demonstrate metrology-grade quality control protocols.

Customization Capacity Verification

Assess scope of personalization supported:

- Design flexibility: Profile types (Cherry, OEM, SA, XDA), color matching (Pantone standards), and engraving options

- Logo integration: Surface printing, laser etching, or insert molding

- Digital workflow: Acceptance of vector artwork (AI/SVG), 3D mockups, and proof generation within 48 hours

Cross-reference stated capabilities with product listings showing consistent graphic alignment and edge finish quality.

Production & Quality Assurance

Evaluate suppliers based on verifiable performance metrics:

- On-time delivery rate ≥97% as an indicator of production planning reliability

- In-house tooling and mold development to reduce dependency on external vendors

- Response time ≤12 hours for iterative design feedback cycles

- Reorder rate above 25% suggests customer satisfaction with consistency and service

While ISO 9001 certification is not universally listed, its presence indicates structured quality management systems. For export compliance, verify adherence to RoHS directives on restricted substances in electrical equipment.

What Are the Best Custom Keycaps Maker Suppliers?

| Company Name | Location | Verification Status | Main Materials | Min. Order Quantity | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Nanjing Xinzhi Zongyuan Electronic Technology Co., LTD | Jiangsu, CN | Multispecialty Supplier | PBT, ABS | 1–100 pieces | 100.0% | ≤7h | US $50,000+ | 15% |

| Shenzhen Yiqi Network Technology Co., Ltd. | Guangdong, CN | Multispecialty Supplier | PBT, Dye-Sub Blanks | 2–10 pieces | 100.0% | ≤9h | US $2,400,000+ | 100% |

| Dongguan Golden Orange Electronics Technology Limited | Guangdong, CN | Custom Manufacturer | PBT, CNC Brass, Metal | 1–50 sets | 100.0% | ≤2h | US $300,000+ | 27% |

| Dongguan Sanyi Mold Co., Ltd. | Guangdong, CN | Not Specified | ABS, PBT | 1 set | 100.0% | ≤12h | US $800+ | <15% |

| Huizhou Xingguang Plastic Products Co., Ltd. | Guangdong, CN | Custom Manufacturer | PBT, Dye-Sublimation Grade | 10 sets | 100.0% | ≤2h | Not Available | Not Available |

Performance Analysis

Shenzhen Yiqi Network Technology stands out with a 100% reorder rate and high online revenue, indicating strong market acceptance and repeat business—key indicators of consistent quality and service reliability. Dongguan Golden Orange and Huizhou Xingguang offer superior responsiveness (≤2h average reply time), critical for managing complex design iterations. Nanjing-based suppliers provide lower entry barriers with single-piece ordering, ideal for prototyping. However, Dongguan Sanyi Mold, despite low reorder rates, maintains perfect on-time delivery, suggesting reliability in execution even if post-sale satisfaction lags. Suppliers with "Custom Manufacturer" designation show deeper investment in dedicated tooling and client-specific workflows.

FAQs

How to verify a custom keycaps maker’s production capability?

Request facility videos highlighting injection molding lines, curing ovens, and inspection stations. Confirm ownership of in-house molds versus third-party sourcing. Ask for batch test reports on dimensional tolerance (±0.1mm standard) and pull-force resistance (minimum 350g for stable switch mounting).

What is the typical sampling timeline for custom keycaps?

Sample production takes 7–14 days depending on complexity. Simple dye-sublimated sets are delivered faster; multi-color double-shot or CNC-machined units require up to 21 days. Add 5–7 days for international express shipping.

Can suppliers accommodate small-batch or one-off custom orders?

Yes, several suppliers accept MOQs as low as one piece, particularly for blank PBT keycaps or personalized single-key prototypes. Full-set customization typically requires minimum 10–20 sets to justify setup costs.

Do manufacturers provide free samples?

Free samples are uncommon for fully customized designs due to tooling and setup expenses. Some suppliers offer discounted first runs or credit toward future bulk orders. Standard blank keycap samples may be provided at nominal cost.

How to initiate a customization project with a keycaps manufacturer?

Submit detailed specifications including keyboard layout (ANSI/ISO), profile type, material preference, color codes (RAL/Pantone), and graphic files (vector format preferred). Reputable makers will return digital proofs within 24–48 hours and initiate mold development upon approval.