Custom Machine Design

Top sponsor listing

Top sponsor listing

About custom machine design

Where to Find Custom Machine Design Suppliers?

China leads global custom machine design manufacturing, with key industrial hubs in Shanghai, Xiamen, and Foshan offering specialized capabilities in precision engineering and rapid prototyping. These regions host vertically integrated supply chains combining CNC machining, sheet metal fabrication, 3D printing, and mold development under one ecosystem. Shanghai and Xiamen are particularly known for advanced R&D infrastructure and proximity to international ports, enabling efficient export logistics and shorter delivery cycles.

The clustering of technical suppliers, material vendors, and logistics providers within compact geographic zones reduces production lead times by 20–30% compared to decentralized markets. Buyers benefit from agile customization workflows—design-to-production cycles average 15–25 days for prototypes and 30–45 days for full-scale batches. Localized access to raw materials such as stainless steel (SS304/316), aluminum alloys, and engineering plastics further enhances cost efficiency, with labor and processing costs remaining 25–40% below Western benchmarks.

How to Choose Custom Machine Design Suppliers?

Selecting reliable partners requires structured evaluation across three critical dimensions:

Technical & Production Capabilities

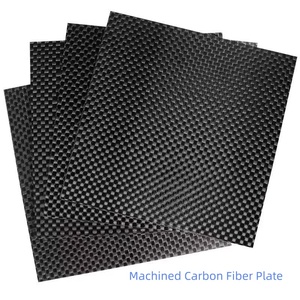

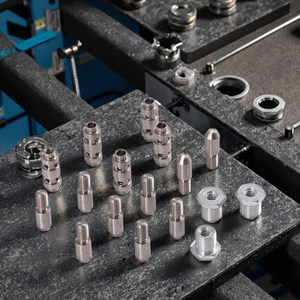

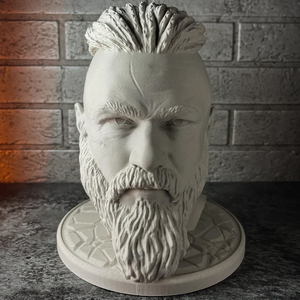

Verify that suppliers maintain in-house design teams and support common CAD/CAM formats (SolidWorks, AutoCAD, STEP, IGES). Essential processing capabilities include multi-axis CNC machining, laser cutting, bending, welding, and additive manufacturing (SLA, SLS, MJF, FDM). Prioritize companies with documented R&D capacity and a diversified service portfolio covering machining, sheet metal, molding, and assembly.

Quality Assurance and Compliance

While formal certifications (e.g., ISO 9001) are not explicitly stated in available data, performance indicators such as on-time delivery rates serve as proxies for operational discipline. Target suppliers with ≥95% on-time delivery and response times under 2 hours. Reorder rates above 40% suggest high client satisfaction and consistent output quality. For regulated industries, confirm compliance with material standards (e.g., RoHS, REACH) and request test reports or sample inspections prior to bulk orders.

Transaction Reliability and Scalability

Assess online transaction volume as an indicator of market presence—suppliers reporting annual revenues exceeding US $200,000 demonstrate established operations. Cross-reference product listings and service breadth: top-tier providers typically offer 100+ machining listings alongside complementary services like 3D printing and mold development. Confirm minimum order quantities (MOQs) align with project scale; many suppliers accommodate MOQs as low as 1–5 pieces for prototype runs.

What Are the Best Custom Machine Design Suppliers?

| Company Name | Location | Main Services (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Key Strengths |

|---|---|---|---|---|---|---|---|

| Anqing Wayne Hand Model Technology Co., Ltd. | Anqing, CN | Machining (1,421), Sheet Metal (166), Molding (132) | 92% | ≤2h | 47% | US $240,000+ | Highest service diversity and transaction volume; strong in rapid prototyping via SLA/SLS/MJF |

| Xiamen Joint Intelligent Technology Co., Ltd. | Xiamen, CN | Sheet Metal (102), Machining (19), Molds (35) | 100% | ≤2h | 17% | US $40,000+ | Perfect on-time delivery; focused on 3D printing and metal fabrication services |

| Foshan Shunde Xianfeng Product Design Modeling Factory | Foshan, CN | Machining (329), Sheet Metal (65), Molds (31) | 91% | ≤5h | 40% | US $80,000+ | High reorder rate indicates customer retention; offers OEM machining and industrial part customization |

| Shanghai Fangyou Precision Machinery Co., Ltd. | Shanghai, CN | Machining (289), Sheet Metal (17), Molds (9) | 100% | ≤1h | <15% | US $9,000+ | Fastest response time; specializes in precision machining with tight tolerances |

| Xiamen Openex Mechanical Technology Limited | Xiamen, CN | Machining (160), Sheet Metal (113), Casting (43) | 100% | ≤3h | - | - | Strong in large-scale machining and heat-treated components; serves heavy equipment sectors |

Performance Analysis

Anqing Wayne stands out for its extensive service catalog and high reorder rate (47%), indicating robust client retention and technical versatility in both traditional and additive manufacturing. Xiamen Joint and Shanghai Fangyou achieve perfect on-time delivery records, with Shanghai Fangyou leading in responsiveness (≤1 hour), making it ideal for time-sensitive design iterations. Despite limited revenue disclosure, Xiamen Openex demonstrates specialization in heavy-duty machining and casting—suitable for industrial-grade applications requiring structural integrity. Foshan Xianfeng balances responsiveness and repeat business, suggesting reliable quality in consumer appliance component manufacturing.

FAQs

How to verify custom machine design supplier reliability?

Evaluate on-time delivery history, reorder rates, and response speed as operational health indicators. Request facility documentation or video tours to confirm in-house machining and design capabilities. Validate material traceability and dimensional accuracy through sample testing before scaling procurement.

What is the typical MOQ and pricing structure?

Most suppliers support low-volume production with MOQs starting at 1 piece, especially for 3D-printed or CNC-machined prototypes. Unit prices range from $0.30 to $100 depending on complexity, material, and finishing requirements. Bulk orders (50+ units) often qualify for tiered pricing and reduced per-unit costs.

What customization options are available?

Suppliers offer end-to-end customization—from concept modeling to finished parts—including geometry adjustments, material substitution, surface treatments (brushing, plating, anodizing), and integration of functional assemblies. Technical drawings or 3D models are required to initiate production.

How long does prototyping take?

Rapid prototyping timelines average 7–15 days for machined or 3D-printed components. Complex designs involving molds or multi-part assemblies may require 20–30 days. Additive methods (SLA, SLS) enable faster iteration compared to tooling-dependent processes.

Can suppliers handle international shipping?

Yes, experienced exporters manage global logistics via air or sea freight under standard Incoterms (FOB, CIF). Confirm packaging standards, export documentation, and destination-specific import regulations during order finalization.