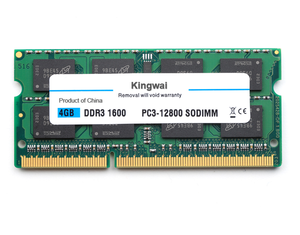

Ddr 3 L

1/3

1/3

1/3

1/3

1/4

1/4

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/2

1/2

0

0

1/2

1/2

1/3

1/3

1/19

1/19

1/2

1/2

1/3

1/3

1/3

1/3

1/1

1/1

About ddr 3 l

Where to Find DDR 3L Suppliers?

No active suppliers for DDR 3L memory modules were identified in the current dataset. This suggests limited or inactive manufacturing and export availability for this specific product category within tracked industrial markets. DDR 3L, a low-voltage variant of DDR3 SDRAM operating at 1.35V, is primarily used in power-sensitive computing applications such as embedded systems, industrial PCs, and legacy server environments. Historically, production has been concentrated among semiconductor manufacturers in East Asia, particularly South Korea, Taiwan, and select Chinese regions with established electronics component ecosystems.

In prior market cycles, suppliers leveraged integrated fabrication plants (fabs) and assembly, testing, and packaging (ATP) facilities to deliver DDR 3L modules with optimized power efficiency and compatibility for industrial-grade applications. However, industry-wide shifts toward DDR4 and DDR5 technologies have led to reduced production capacity and phased-out lines for DDR3 variants. As a result, available supply is increasingly limited to secondary markets, surplus inventory, or specialized rebuilders reconditioning existing modules. Buyers seeking DDR 3L components should anticipate challenges related to long-term availability, authenticity verification, and traceability of materials.

How to Choose DDR 3L Suppliers?

Given the declining production lifecycle of DDR 3L, procurement strategies must emphasize technical validation and supply chain transparency:

Technical Compliance

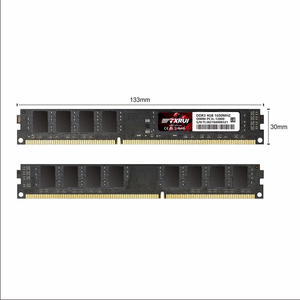

Verify adherence to JEDEC JESD209-3 standards governing DDR3L electrical specifications, including voltage tolerance (1.35V ±0.1V) and timing parameters. For industrial applications, confirm extended temperature range support (-40°C to +85°C) and error-correcting code (ECC) functionality if required. Demand test reports from burn-in procedures and signal integrity analysis.

Production Capability Audits

Evaluate supplier infrastructure for module assembly and testing:

- Presence of automated surface-mount technology (SMT) lines for consistent IC placement

- In-house memory testing using specialized equipment (e.g., Xeltek, Beken) to validate data retention and speed grades

- Traceability systems that log batch numbers, PCB revisions, and IC origin

Prioritize suppliers offering full material disclosure, especially regarding DRAM die sources (e.g., Samsung, SK Hynix, Micron).

Transaction Safeguards

Utilize secure payment methods with milestone-based releases, particularly when sourcing from non-franchised or independent suppliers. Require third-party inspection services for large orders to verify module markings, PCB quality, and functional performance. Given the prevalence of remarking and counterfeit modules in legacy memory markets, sample testing under real-world workloads is critical before scaling procurement.

What Are the Best DDR 3L Suppliers?

At this time, no verified DDR 3L module suppliers are documented in the available dataset. The absence of operational profiles—covering factory size, delivery performance, staff count, or certification status—reflects broader industry trends: mainstream manufacturers have discontinued DDR3L production in favor of newer memory architectures. Remaining supply sources may include:

- Specialized rebuilders refurbishing used DDR3 modules to 3L specifications

- Distributors holding obsolete stock from original manufacturers

- Regional ATP houses assembling modules from imported DRAM chips

These sources often lack standardized quality management systems and may not provide long-term supply guarantees.

Performance Analysis

With no active supplier metrics available, buyers must shift focus from comparative performance to risk mitigation. Where DDR 3L remains necessary for system compatibility, prioritize partners who can demonstrate provenance through datasheets, lot tracing, and functional warranties. Consider migration planning toward DDR4-compatible platforms to ensure sustainable sourcing and reduce dependency on diminishing component availability.

FAQs

How to verify DDR 3L supplier reliability?

Request documentation of compliance with JEDEC standards and evidence of testing protocols. Cross-reference supplier claims with independent reviews or industry databases. For high-volume needs, conduct on-site audits or commission third-party lab testing to confirm module authenticity and performance consistency.

What is the average sampling timeline?

Sampling lead times vary significantly due to limited production. Expect 10–20 days for available stock samples, with longer durations (up to 6 weeks) if modules require reconfiguration or rebuilding. Air freight adds 5–7 days for international delivery.

Can suppliers ship DDR 3L modules worldwide?

Yes, but shipping depends on stock availability and export compliance. Confirm whether the supplier adheres to international trade regulations, including ECCN classification (typically EAR99 for standard memory modules) and RoHS compliance for hazardous substances.

Do manufacturers provide free samples?

Free samples are uncommon due to the niche status of DDR 3L. Most suppliers charge a nominal fee to cover handling and materials, which may be credited toward a formal purchase order. Exceptions occur when fulfilling large-scale retrofit or industrial upgrade contracts.

How to initiate customization requests?

Submit detailed requirements including capacity (4GB, 8GB), speed grade (PC3L-12800/1600MHz), form factor (DIMM, SO-DIMM), and special features (ECC, registered buffers). Reputable rebuilders can typically provide prototype modules within 3–4 weeks, accompanied by test logs and compatibility reports.