Desktop 5 Axis Cnc Machine Producer

About desktop 5 axis cnc machine producer

Where to Find Desktop 5-Axis CNC Machine Producers?

China remains the global epicenter for desktop 5-axis CNC machine manufacturing, with key production clusters in Shaanxi, Shandong, and Guangdong provinces. These regions host vertically integrated facilities that combine precision engineering, component sourcing, and final assembly within compact industrial zones. Shaanxi’s Xi’an area specializes in high-precision machining centers, leveraging aerospace-grade standards for consistent accuracy. Shandong's Jinan and Weifang hubs focus on scalable production of multi-material CNC systems, supported by regional metalworking and automation supply chains. Guangdong’s Shenzhen zone excels in R&D-driven miniaturization, enabling compact desktop units without compromising rigidity or performance.

The concentration of suppliers in these areas allows for optimized logistics, reduced component lead times, and rapid prototyping cycles. Buyers benefit from localized ecosystems where motors, controllers, ball screws, and structural components are sourced within 100km, reducing dependency on external imports. This integration supports faster order fulfillment—typically 30–45 days for standard configurations—and enables cost efficiencies of 20–35% compared to equivalent Western-built machines. The presence of export-oriented manufacturers also ensures compliance with international packaging, labeling, and documentation standards for seamless customs clearance.

How to Choose Desktop 5-Axis CNC Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer true simultaneous 5-axis motion control, not just indexed (3+2 axis) functionality. Request detailed specifications on spindle speed (typically 8,000–24,000 RPM), positioning accuracy (±0.005mm standard), and repeatability. Evaluate controller compatibility—support for industry-standard systems like Mach4, LinuxCNC, or proprietary software such as JW-U500 is essential for integration flexibility. For metal cutting applications, verify use of hardened linear guides, servo-driven axes, and thermal compensation features.

Production Infrastructure Assessment

Prioritize suppliers with documented in-house capabilities across core processes:

- Minimum factory area exceeding 3,000m² to support dedicated machining, assembly, and testing lines

- In-house CNC milling and grinding capacity for frame fabrication and calibration

- Dedicated quality inspection stations using laser interferometers or ballbar testers

Cross-reference online revenue data and on-time delivery rates (target ≥98%) as indicators of stable operations and supply chain resilience.

Quality & Compliance Standards

While ISO 9001 certification is not universally listed, its absence should prompt deeper due diligence. CE marking is critical for European market access, indicating compliance with EMC and Machinery Directive requirements. Request evidence of EMI shielding, emergency stop circuit validation, and grounding integrity. For medical or aerospace applications, probe further into traceability protocols, material certifications (e.g., aluminum 6061-T6), and environmental testing records.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with delivery milestones. Analyze reorder rates as a proxy for customer satisfaction—rates above 30% suggest dependable post-sale support and machine reliability. Insist on pre-shipment inspection (PSI) by third-party agencies like SGS or TÜV for orders over $20,000. Sample testing remains vital: assess surface finish quality, corner blending, and tool path fidelity using standardized test pieces before full-scale procurement.

What Are the Leading Desktop 5-Axis CNC Machine Producers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shaanxi Jingwei Hongbo Cnc Equipment Co., Ltd. | Shaanxi, CN | Machining Centre, CNC Milling Machines | $19,999–74,000 | 1 unit | 100% | ≤1h | <15% | US $100+ |

| Shandong Chencan Machinery Incorporated Company | Shandong, CN | Wood Routers, Machining Centre, 3D Printers | $120,000–630,000 | 1 set | 100% | ≤1h | 75% | US $190,000+ |

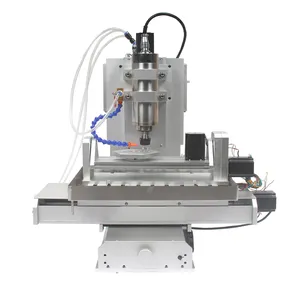

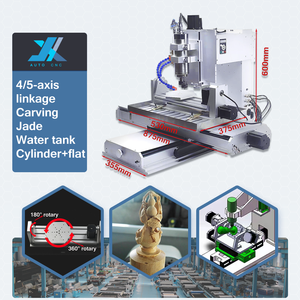

| Shenzhen Yu Diao Cnc Technology Co., Ltd. | Guangdong, CN | CNC Engraving, Wood Routers, Metal Engraving | $12,000–35,000 | 1 set | 100% | ≤1h | 33% | US $100,000+ |

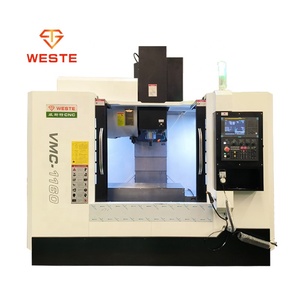

| Ningbo Maxtors Cnc Machinery Co., Ltd. | Zhejiang, CN | CNC Milling, Machining Centre, CNC Lathe | $18,998–340,000 | 1 set | 100% | ≤4h | - | - |

| Shandong Shanshu Machinery Co., Ltd. | Shandong, CN | Wood Routers, Woodworking Machinery | $20,000–80,000 | 1 set | 100% | ≤3h | 33% | US $120,000+ |

Performance Analysis

Shandong Chencan stands out with the highest reorder rate (75%), indicating strong customer retention likely driven by specialized solutions for foam modeling, boat molds, and statue carving. Despite higher price points, their investment in overseas service and training infrastructure suggests readiness for international deployment. Shenzhen Yu Diao offers the most competitive entry-level pricing ($12,000–$15,000 for DIY desktop models), making it suitable for educational institutions and small workshops seeking affordable prototyping tools. Shaanxi Jingwei Hongbo provides mid-range versatility with options spanning standalone machines and controllers, though its low reorder rate (<15%) may reflect limited after-sales engagement. Ningbo Maxtors covers an unusually wide price spectrum, from compact VMC-5 units at $37,500 to bridge-type systems exceeding $340,000, signaling capability in both desktop and industrial-scale segments despite incomplete response metrics. Shandong Shanshu focuses on wood-centric applications with dual offerings in rotary and flatbed 5-axis configurations, catering to mold makers and furniture artisans.

FAQs

What is the typical MOQ for desktop 5-axis CNC machines?

Most suppliers list a minimum order quantity of 1 unit or set, allowing single-machine procurement for evaluation or low-volume production. Bulk discounts typically begin at 3+ units, with negotiated freight terms available for container-sized shipments.

How long does production and shipping take?

Lead time averages 30–45 days for standard configurations after deposit confirmation. Custom modifications—such as spindle upgrades, enclosure integration, or coolant systems—may extend this by 10–20 days. Air freight delivers in 5–10 days but is cost-prohibitive for heavy machinery; sea freight remains optimal for full or shared containers, taking 25–35 days depending on destination port.

Can desktop 5-axis CNC machines process metal?

Yes, but capability varies. Entry-level models (e.g., HOGRUPPE series) are optimized for aluminum, plastics, and wax. Higher-end variants (e.g., JW-U640, VMC-855) feature reinforced spindles and rigidity for steel and titanium machining. Always confirm material-specific torque curves and feed rate limits prior to purchase.

Do suppliers offer customization options?

All listed manufacturers support some level of customization, including work envelope adjustments, tool changer integration, probing systems, and software interface preferences. Submit detailed technical drawings or STL files to initiate quoting. Prototypes can often be delivered within 4 weeks upon approval.

Are spare parts and technical support available internationally?

Leading suppliers like Shandong Chencan provide overseas service networks and remote diagnostics. Others may require coordination through local agents. Verify availability of replacement spindles, drive motors, and control boards before deployment. Some offer online training modules and multilingual manuals to reduce downtime.