Diffuser Bottle Suppliers

Top sponsor listing

Top sponsor listing

About diffuser bottle suppliers

Where to Find Diffuser Bottle Suppliers?

China remains the dominant hub for diffuser bottle manufacturing, with key production clusters in Shandong and Jiangsu provinces. These regions host vertically integrated glass and packaging facilities that support high-volume output and advanced customization. Shandong, home to Jinan and Zaozhuang, features specialized industrial zones focused on glass processing and closure systems, enabling tight coordination between raw material sourcing and finished product assembly. Jiangsu’s Xuzhou region has emerged as a center for premium fragrance packaging, offering access to skilled labor in glass blowing, surface treatment, and precision molding.

The concentration of suppliers in these areas facilitates economies of scale, with many manufacturers operating automated filling and inspection lines capable of producing over 500,000 units monthly. Proximity to ports like Qingdao and Lianyungang reduces logistics costs and export lead times, making these clusters particularly efficient for international buyers. The ecosystem supports both standard and custom configurations—ranging from basic amber vials to luxury reed diffuser sets with magnetic closures and silk-screened branding.

How to Choose Diffuser Bottle Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional criteria:

Material & Process Capabilities

Confirm supplier expertise in borosilicate or soda-lime glass forming, including cold-end coating and thermal shock resistance testing. For plastic components (caps, pumps), verify injection molding capacity and compatibility with essential oils. Evaluate customization options such as frosted finishes, hot stamping, engraving, and color-tinting processes. Suppliers should offer dimensional control down to ±0.1mm for cap sealing integrity.

Quality Assurance Systems

Prioritize suppliers implementing ISO 9001-certified quality management systems. While not always explicitly stated, compliance with RoHS and REACH standards is critical for EU market access. Request batch-specific test reports for leak resistance, cap torque retention, and UV stability—especially for clear or light-sensitive formulations. On-time delivery rates above 92% indicate consistent process reliability.

Customization and Minimum Order Requirements

Assess flexibility in volume, design, and labeling. MOQs vary significantly: some suppliers accept as few as 10–20 pieces for sample validation, while bulk pricing typically begins at 500–1,000 units. Custom tooling for unique neck finishes or decorative elements may require NRE fees and extended lead times (4–6 weeks). Digital proofing and pre-production samples are standard practice before mass runs.

Transaction Reliability Indicators

Review reorder rates as proxies for customer satisfaction—values exceeding 25% suggest strong post-sale performance. Response times under 3 hours reflect organizational efficiency. Cross-reference online revenue estimates with order history to assess scalability. Where available, prefer suppliers with documented quality control checkpoints and third-party audit trails.

What Are the Best Diffuser Bottle Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Verified Type |

|---|---|---|---|---|---|---|---|

| Jinan Youlyy Industrial Co., Ltd. | Glass Bottles, Lids, Caps & Closures, Medical Consumables | Color, label, anti-theft ring, volume, cap diameter, stopper, logo, graphic, injection moulded | 97% | 26% | ≤3h | US $550,000+ | Custom Manufacturer |

| Hebei Welllive Trade Co., Ltd. | Car Air Fresheners, Eco-Friendly Diffusers, Home Fragrance Bottles | Engraving, frosting, silk printing, hot stamping, woodgrain, bamboo, magnetic box, pump head, gasket, packaging | 94% | 18% | ≤3h | US $350,000+ | Multispecialty Supplier |

| Xuzhou Yongshine International Trading Co., Ltd. | Glass Bottles, Candle Holders, Jars, Decorative Objects | Limited data; likely standard finishes and volumes | 94% | <15% | ≤2h | US $390,000+ | Not specified |

| Xuzhou Eric Glass Products Company | Glass Bottles, Jars | Basic customization (color, capacity) | 92% | 18% | ≤3h | US $30,000+ | Not specified |

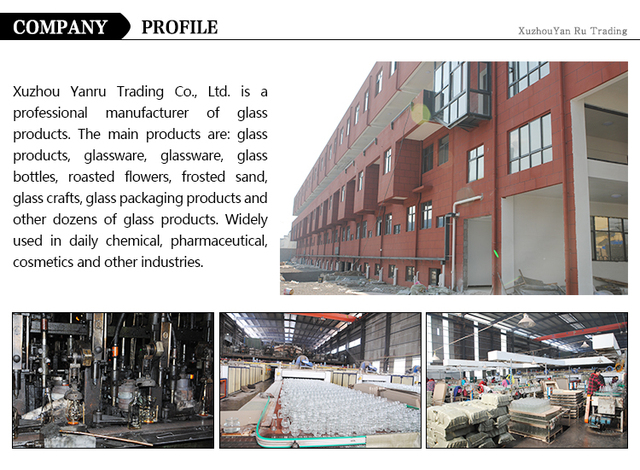

| Xuzhou Yanru Trading Co., Ltd. | Glass Bottles, Vases, Drinkware, Candle Jars | Round shape, black finish, custom luxury designs | 81% | 27% | ≤5h | US $130,000+ | Not specified |

Performance Analysis

Jinan Youlyy stands out with the highest on-time delivery rate (97%) and strong reorder performance (26%), supported by extensive customization capabilities in closure systems and molded components—ideal for branded or medical-grade applications. Hebei Welllive offers broad aesthetic customization, including eco-friendly materials and premium packaging, though its lower reorder rate suggests potential gaps in consistency. Xuzhou Yongshine combines fast response times (≤2h) with moderate reliability (94% delivery), serving niche markets requiring small MOQs and rapid turnaround. Xuzhou Yanru, despite a relatively low on-time delivery score (81%), maintains a high reorder rate (27%), indicating strong post-delivery satisfaction, possibly due to design quality or after-sales service. Buyers seeking volume stability should prioritize suppliers with verified manufacturing status and delivery rates exceeding 94%.

FAQs

What materials are commonly used in diffuser bottles?

Glass (amber, clear, or colored soda-lime/borosilicate) is standard for UV protection and chemical inertness. Plastic variants (PET, PP) are used for lightweight or impact-resistant applications. Caps and dispensers often use aluminum, polypropylene, or silicone seals to prevent evaporation and leakage.

What is the typical lead time for diffuser bottle orders?

Standard orders take 15–25 days from confirmation. Custom molds or surface treatments may extend lead times to 35–45 days. Air shipping adds 7–10 days internationally; sea freight ranges from 25–40 days depending on destination.

Can suppliers provide free samples?

Most suppliers offer paid samples (often 1–2 units at retail price) to cover material and handling. Some waive fees for future bulk orders. Custom samples may incur tooling charges, especially for new molds or print designs.

What certifications should diffuser bottle suppliers have?

ISO 9001 is the baseline for quality management. For export to regulated markets, ensure compliance with RoHS (EU), FDA (USA) for food-contact materials, and REACH for chemical safety. Third-party lab reports for extractables and leachables add verification depth.

How do I verify supplier production claims?

Request facility videos showing filling lines, QC stations, and warehouse operations. Ask for client references or third-party audit summaries. Conduct virtual factory tours to observe mold setup, annealing ovens, and leak testing procedures before placing large orders.