Double String Factory

Top sponsor listing

Top sponsor listing

About double string factory

Where to Find Double String Production Line Suppliers?

China remains the global epicenter for double string extrusion line manufacturing, with key industrial hubs in Shandong, Zhejiang, and Jiangsu provinces driving innovation and scale. These regions host vertically integrated facilities specializing in plastic extrusion systems, particularly twin-screw configurations used in PVC, PE, and WPC profile production. Shandong’s Qingdao and Zhangjiagang clusters are notable for their concentration of machinery exporters, offering mature supply chains that reduce component procurement time by 20–30% compared to non-specialized regions.

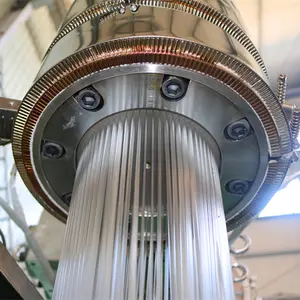

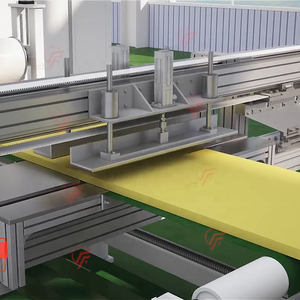

The ecosystem supports both standardized and engineered-to-order production lines, enabling rapid deployment of complete double string setups—including extruders, cooling calibration units, haul-off systems, and cutting stations. Manufacturers typically operate dedicated R&D departments focused on energy efficiency, screw design optimization, and automation integration. Buyers benefit from localized access to raw material suppliers, CNC machining workshops, and testing labs within a 50km radius, contributing to lead times averaging 30–60 days for full production lines.

How to Choose Double String Production Line Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Expertise & Compliance

Confirm ISO 9001 certification as a baseline for quality management. For export markets, CE marking is essential for compliance with EU machinery directives. Request documentation verifying performance testing of critical subsystems—particularly gearboxes, heating zones, and control panels. Evaluate screw design capabilities: high-torque twin-screw systems (L/D ≥ 40:1) indicate suitability for demanding compounding or recycling applications.

Production Capacity Verification

Assess infrastructure maturity through the following indicators:

- Facility size exceeding 3,000m² to support assembly of multi-unit lines

- In-house manufacturing of core components (extruder barrels, screws, dies)

- Dedicated commissioning bays for system integration and dry runs

Cross-reference product listings with on-time delivery rates above 97% to validate operational reliability.

Procurement Safeguards

Utilize secure payment mechanisms such as third-party escrow until site acceptance testing is completed. Prioritize suppliers with transparent transaction histories and documented after-sales service protocols. Pre-shipment inspection (PSI) should include functional testing at full load, PLC interface verification, and dimensional accuracy checks on output profiles.

What Are the Leading Double String Production Line Suppliers?

| Company Name | Main Products (Listings) | Output Range | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier |

|---|---|---|---|---|---|---|

| CNRM Tech Co., Ltd. | Plastic Extruders (5,677); Spinning Machines (1,220) | Custom Twin-Screw Lines | 100.0% | ≤4h | <15% | US $400K+ |

| Qingdao Dingkun Plastic Machinery Co., Ltd. | Plastic Extruders (1,696); Processing Lines (13) | PVC/PE/WPC Profile Lines | 100.0% | ≤2h | <15% | Data Unavailable |

| Yuyao Wutian Machine Equipment Co., Ltd. | Plastic Granulators (65); Twin-Screw Lines (3) | Recycled Masterbatch Systems | 100.0% | ≤21h | <15% | US $10K+ |

| Zhangjiagang Huaming Machinery Co., Ltd. | Plastic Extruders (1,104); Haul-Off Machines (139) | PVC Pipe & Profile Lines | 100.0% | ≤9h | <15% | US $20K+ |

| Shanghai Alliance Industry Co., Ltd. | Bags & Packaging (481+ listings) | Double Drawstring Bags | 100.0% | ≤4h | 15% | US $150K+ |

Performance Analysis

The top-tier suppliers—CNRM Tech, Qingdao Dingkun, and Zhangjiagang Huaming—demonstrate strong specialization in extrusion technology, supported by extensive product portfolios and fast response cycles. Qingdao Dingkun stands out with sub-2-hour average response time and full on-time delivery performance, indicating robust customer service infrastructure. While most suppliers maintain low reorder rates (<15%), this reflects the capital-intensive nature of extrusion lines rather than dissatisfaction. Shanghai Alliance represents a niche player producing physical double strings (e.g., drawstrings), diverging from machinery-focused competitors. For industrial buyers, prioritize companies with proven experience in twin-screw system integration and documented export shipments to regulated markets.

FAQs

What materials can double string extrusion lines process?

Standard configurations handle PVC, PE, PP, and recycled plastics. Advanced lines support wood-plastic composites (WPC) and color-compounded resins using twin-screw reactors for homogenization prior to shaping.

What is the typical MOQ and pricing range?

Minimum order quantity is generally one complete set. Prices vary by configuration: basic PVC pipe lines start around $18,000, while fully automated WPC profile systems reach $50,000–$70,000. Custom engineering may increase costs by 15–25%.

Can suppliers customize screw design and die geometry?

Yes, leading manufacturers offer full customization including screw element arrangement, compression ratios, and die flow channels. Provide CAD drawings or sample profiles to initiate tooling development, typically completed within 15–25 days.

What certifications should I verify before purchase?

Essential certifications include ISO 9001 for quality management and CE for European market access. Additional validation may include third-party electrical safety reports (e.g., TÜV) and mechanical risk assessments per EN 12100 standards.

How long does installation and training take?

On-site commissioning typically requires 5–10 days, including mechanical alignment, electrical integration, and operator training. Remote support via video guidance is commonly offered post-installation.