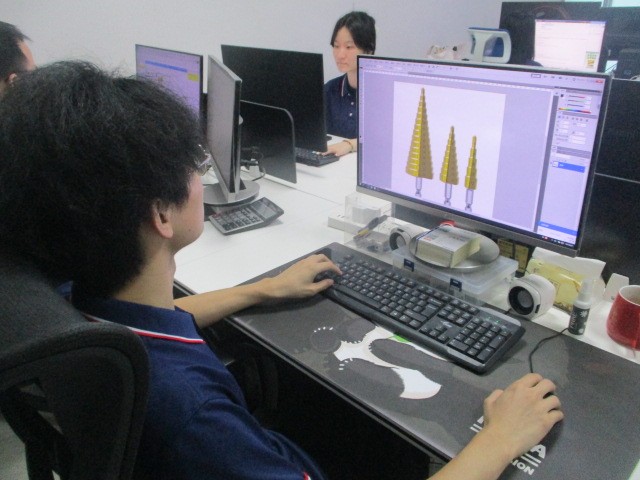

Drill Bit Set Distributor

Top sponsor listing

Top sponsor listing

1/19

1/19

1/6

1/6

1/10

1/10

0

0

1/17

1/17

1/30

1/30

0

0

1/3

1/3

1/27

1/27

1/2

1/2

0

0

1/3

1/3

1/21

1/21

1/5

1/5

About drill bit set distributor

Where to Find Drill Bit Set Distributors?

China remains the global epicenter for drill bit set manufacturing and distribution, with key industrial hubs in Jiangsu, Guangdong, Sichuan, and Shanghai driving supply chain efficiency. These regions host vertically integrated facilities specializing in high-speed steel (HSS), carbide, and cobalt alloy tool production, enabling cost-effective scaling for both standard and customized sets. Proximity to raw material sources and port infrastructure—particularly in Shanghai and Shenzhen—reduces logistics lead times by 10–15% compared to offshore alternatives.

Suppliers in these clusters benefit from mature ecosystems encompassing precision grinding, heat treatment, coating technologies, and packaging operations within compact geographic radii. This integration supports rapid prototyping and batch fulfillment, with typical lead times ranging from 15 to 30 days for bulk orders. Buyers gain access to flexible MOQs—from as low as 10 sets for niche configurations to 500+ pieces for mass procurement—alongside robust customization capabilities in size, material grade, shank type, and branding.

How to Choose Drill Bit Set Distributors?

Evaluate potential partners using the following criteria to ensure reliability, quality consistency, and transaction security:

Quality Assurance & Compliance

Prioritize suppliers demonstrating adherence to international standards such as ISO 9001 for quality management. While not always explicitly stated, compliance with RoHS and CE directives is essential for market access in Europe and North America. Request test reports on hardness (HRC 63–67 for HSS-M35), concentricity tolerance (≤0.02mm), and surface finish quality to validate performance claims.

Production and Customization Capacity

Assess operational scale through verifiable metrics:

- Facility size and monthly output capacity (suppliers with >US$200,000 online revenue typically support volume orders)

- In-house processing capabilities including CNC grinding, laser marking, and heat treatment

- Customization scope: diameter range (0.5–13mm common), flute design, coating options (TiN, TiAlN), and packaging personalization

Confirm customization feasibility via sample requests before full-scale ordering.

Transaction Reliability Indicators

Leverage performance data to mitigate sourcing risk:

- On-time delivery rate ≥95% indicates stable production planning

- Average response time ≤4 hours reflects strong customer service infrastructure

- Reorder rates above 20% signal customer satisfaction and product consistency

Cross-reference these metrics with order history and buyer feedback where available.

What Are the Top Drill Bit Set Distributors?

| Company Name | Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | MOQ Range |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Feida Drills Co., Ltd. | Custom Manufacturer | Drill Bits, Carbide Tools, Milling Cutters | US $20,000+ | 100% | ≤1h | 17% | Yes | 500 pcs |

| Shanghai Ruixian Industrial Co., Ltd. | Multispecialty Supplier | Drill Bit Sets, Hardware Tool Kits | US $7,000+ | 71% | ≤13h | <15% | Yes | 500 pcs |

| Shenzhen Ruizh Industrial Co., Ltd. | Multispecialty Supplier | HSS, M35, Diamond Bits | US $200,000+ | 100% | ≤2h | <15% | Yes | 10–500 pcs |

| Sichuan Machinery Tools Import & Export Co., Ltd. | Multispecialty Supplier | Carbide, HSS, Diamond Sets | US $340,000+ | 98% | ≤4h | 15% | Yes | 2–500 pcs |

| Foshan Songqi Technology Co., Ltd. | Custom Manufacturer | HSS-M35, Cobalt, Twist Bits | US $900,000+ | 95% | ≤1h | 22% | Yes | 10–100 pcs |

Performance Analysis

Foshan Songqi Technology stands out with the highest reported online revenue (US $900,000+) and a 22% reorder rate, indicating strong market acceptance and repeat business. Jiangsu Feida and Shenzhen Ruizh achieve perfect on-time delivery records (100%), suggesting disciplined production scheduling. In contrast, Shanghai Ruixian’s lower delivery rate (71%) may pose fulfillment risks for time-sensitive contracts.

Custom manufacturers like Jiangsu Feida and Foshan Songqi offer engineering control over material selection and tool geometry, making them ideal for OEM partnerships. Multispecialty suppliers such as Sichuan Machinery Tools provide broader catalog flexibility with low MOQs (as low as 2 sets), suitable for distributors testing new product lines. Buyers prioritizing responsiveness should engage suppliers with sub-2-hour average reply times, a trait observed in three of the five listed companies.

FAQs

How to verify drill bit set supplier reliability?

Cross-check declared certifications with third-party verification platforms. Request evidence of quality control processes, including incoming material inspection, in-process gauging, and final batch testing. Analyze transaction histories focusing on dispute resolution outcomes and shipment accuracy.

What is the typical sampling timeline for drill bit sets?

Standard samples are typically produced within 7–14 days. Custom designs involving unique coatings or non-standard dimensions may require 18–25 days. Air shipping adds 5–10 days for international delivery.

Can drill bit set suppliers handle global exports?

Yes, all listed suppliers have demonstrated export capability through established logistics channels. Confirm Incoterms (FOB, CIF), packaging requirements, and compliance documentation (e.g., MSDS for coated tools) prior to order placement.

Do suppliers offer free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to future volume orders. Otherwise, expect to cover production and shipping costs, typically ranging from $10–$50 per sample set.

How to initiate customization for drill bit sets?

Submit detailed specifications including material type (HSS, M35, carbide), diameter range, shank configuration (hex, straight), coating preference, and packaging layout. Reputable suppliers will provide technical validation and sample prototypes within 10–15 days.