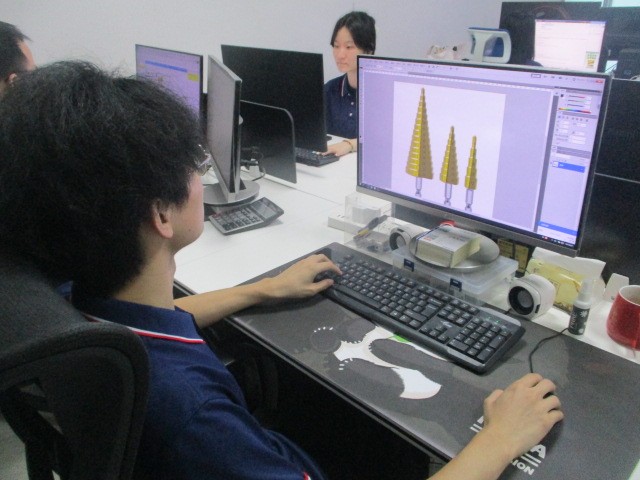

Drill Bit Set

Top sponsor listing

Top sponsor listing

0

0

1/10

1/10

1/3

1/3

0

0

0

0

1/3

1/3

1/32

1/32

1/6

1/6

1/30

1/30

0

0

1/3

1/3

1/3

1/3

1/30

1/30

1/3

1/3

1/2

1/2

1/3

1/3

1/29

1/29

0

0

0

0

About drill bit set

Where to Find Drill Bit Set Suppliers?

China remains the central hub for drill bit set manufacturing, with key production clusters in Jiangsu, Danyang, and Sichuan provinces driving global supply. These regions host vertically integrated facilities specializing in high-speed steel (HSS), titanium-coated, and carbide-tipped drill bit production. Jiangsu and Danyang are particularly known for precision machining and export-oriented tool manufacturing, supported by mature ecosystems of raw material suppliers, heat treatment services, and logistics networks.

The industrial clusters enable cost efficiency and scalability, with localized access to tungsten, vanadium, and molybdenum alloys critical for durable cutting tools. Manufacturers benefit from streamlined production cycles—ranging from blank forging to CNC grinding and surface coating—allowing lead times as short as 15–30 days for standard orders. Buyers gain flexibility in order volume, with MOQs ranging from 1 set for sample testing to 2,000+ sets for bulk procurement. The region’s specialization also supports rapid customization of diameter ranges, flute geometry, shank types, and packaging configurations.

How to Choose Drill Bit Set Suppliers?

Selecting reliable suppliers requires a structured evaluation of operational performance, technical capability, and transactional reliability:

Quality and Compliance Verification

Confirm adherence to international standards such as ISO 9001 for quality management. While not explicitly stated in all supplier profiles, CE or RoHS compliance should be verified for markets in Europe and North America. Request test reports on hardness (HRC 63–67 for HSS bits), wear resistance, and concentricity tolerance (≤0.02mm) to validate performance claims.

Production Capacity Assessment

Evaluate key indicators of manufacturing stability:

- On-time delivery rate exceeding 98% to ensure supply chain continuity

- Response time under 6 hours for timely communication

- Reorder rates above 15% as an indicator of customer satisfaction

- Evidence of in-house processing capabilities including grinding, coating, and inspection

Suppliers with online revenue exceeding US $100,000 demonstrate consistent market presence and order fulfillment capacity. Prioritize those offering customization options such as laser branding, color coding, and retail-ready packaging.

Procurement Safeguards

Utilize secure payment terms with milestone-based releases. Require product samples before full-scale ordering to assess dimensional accuracy, edge sharpness, and packaging quality. Verify packaging durability through drop tests, especially for container shipments. For large-volume contracts, consider third-party inspections at origin to confirm lot consistency and compliance with agreed specifications.

What Are the Best Drill Bit Set Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Naipu Tool Co., Ltd. | Drill Bits, Tool Parts, Milling Cutters, Reamers | 100% | 15% | ≤3h | $20,000+ | Not specified | Not specified | Not specified |

| Danyang Yongchang Tools Co., Ltd. | Drill Bits, Saw Blades, Tap & Die, Chisels | 100% | <15% | ≤3h | $900+ | Not specified | 1–50 sets | $2.00–$3.40 |

| Sichuan Machinery Tools Import & Export Co., Ltd. | Drill Bits, Tool Sets, Bearings | 98% | 15% | ≤5h | $370,000+ | Color, size, logo, packaging, label, graphic | 10–2,000 sets | $2.00–$23.00 |

| Sichuan Tranrich Abrasives Co., Ltd. | Abrasive Tools, Drill Bits, Milling Cutters | 100% | 25% | ≤12h | $30,000+ | Not specified | 10 pieces or sets | $0.10–$3.08 |

| Danyang Felda Tools Co., Ltd. | Drill Bits, Tool Sets, Wrenches, Screwdrivers | 98% | <15% | ≤6h | $110,000+ | Not specified | 1–100 sets | $1.40–$25.00 |

Performance Analysis

Sichuan Machinery Tools Import & Export Co., Ltd. stands out with the highest reported online revenue ($370,000+) and comprehensive customization capabilities, making it ideal for private-label and retail-focused buyers. Despite a slightly lower on-time delivery rate (98%), its wide MOQ adaptability and multi-tiered pricing support both small distributors and large-volume importers.

Sichuan Tranrich Abrasives demonstrates strong customer retention with a 25% reorder rate and competitive pricing starting at $0.10 per piece, indicating efficient production and value positioning. However, slower response times (≤12h) may affect urgent order coordination.

Jiangsu Naipu and Danyang Yongchang maintain perfect on-time delivery records and sub-3-hour response times, reflecting robust operational discipline. These suppliers are suitable for buyers prioritizing reliability and fast communication, though detailed pricing and MOQ data are limited.

Danyang Felda offers broad product integration within tool kits and competitive bulk pricing ($1.40/set), but its reorder rate suggests room for improvement in post-sale satisfaction or consistency.

FAQs

How to verify drill bit set supplier reliability?

Cross-check claimed certifications (e.g., ISO 9001) with official databases. Request evidence of in-house quality control processes, including hardness testing, runout measurement, and batch traceability. Analyze transaction history, focusing on delivery consistency and dispute resolution outcomes.

What is the typical lead time for drill bit set orders?

Standard orders typically ship within 15–30 days after confirmation. Sample lead times range from 5–10 days. Customized orders with branding or special dimensions may require an additional 7–14 days depending on complexity.

Can suppliers provide custom packaging and branding?

Yes, select suppliers like Sichuan Machinery Tools offer full customization including color boxes, blister cards, UPC labeling, and logo printing. Minimum order quantities apply, typically starting at 1,000 units for branded packaging.

What materials are commonly used in drill bit sets?

High-Speed Steel (HSS) is standard for general-purpose drilling. Titanium Nitride (TiN) and Black Oxide coatings enhance wear resistance and heat dissipation. Cobalt-alloy (HSS-Co) bits are used for hardened metals. Carbide tips are employed in masonry and composite material applications.

What are the common MOQs for drill bit sets?

MOQs vary significantly: 1–10 sets for trial orders, 50–100 sets for wholesale pricing, and up to 2,000 sets for fully customized configurations. Some suppliers quote per piece for component-level sales (e.g., individual drill bits).