Electronic Prototype Service

Top sponsor listing

Top sponsor listing

CN

CN

About electronic prototype service

Where to Find Electronic Prototype Service Suppliers?

China's electronic prototype manufacturing sector is concentrated in the Pearl River Delta and Yangtze River Delta regions, with Shenzhen, Guangzhou, and Suzhou emerging as key hubs for rapid prototyping services. These clusters offer integrated ecosystems combining PCB fabrication, 3D printing, CNC machining, and assembly capabilities within close geographic proximity. Shenzhen leads in high-mix, low-volume electronics development, supported by a dense network of component suppliers and contract manufacturers. Suzhou leverages advanced industrial automation and quality management systems to serve precision-focused clients in medical, automotive, and IoT sectors.

The region’s mature supply chain enables fast iteration cycles—typical lead times range from 3–7 days for PCB prototypes and 5–10 days for custom enclosures or injection-molded parts. Vertical integration allows seamless transitions from design validation to small-batch production, with many suppliers offering turnkey solutions including material sourcing, functional testing, and compliance documentation. Buyers benefit from competitive pricing (average unit costs 20–40% below Western counterparts), scalable output, and access to multi-process fabrication technologies under one roof.

How to Choose Electronic Prototype Service Suppliers?

Evaluate potential partners using these critical criteria:

Technical Capability Verification

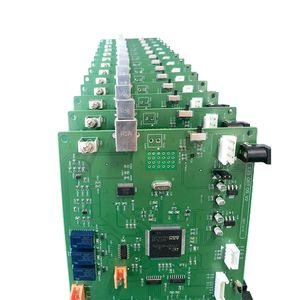

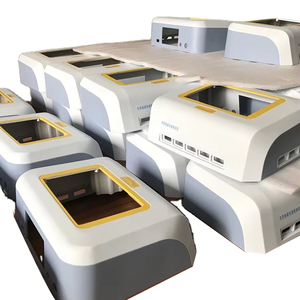

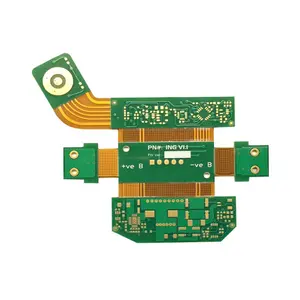

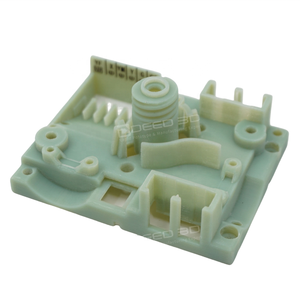

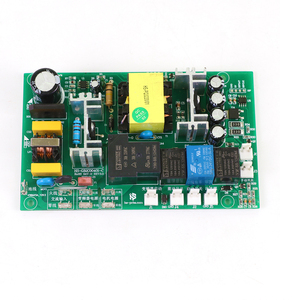

Confirm expertise in relevant prototyping methods: SMT for PCBA, SLA/SLS/FDM for 3D-printed components, vacuum casting for urethane prototypes, and CNC machining for metal or engineering-grade plastic housings. For electronics-integrated builds, verify experience with impedance control, blind/buried vias, and thermal management in multilayer PCBs (up to 16 layers). Demand evidence of process validation through first-article inspection reports or IPC-A-610-compliant QA procedures.

Production Infrastructure Assessment

Prioritize suppliers with in-house capabilities across key processes:

- Minimum 1,000m² workshop area supporting concurrent project execution

- Dedicated R&D or engineering support teams for DFM feedback

- On-site 3D printing (SLA, SLS), CNC, and PCB assembly lines

Cross-reference facility size with on-time delivery performance (target ≥90%) and reorder rates to assess operational stability.

Quality & Transaction Assurance

Require adherence to ISO 9001 standards and material compliance with RoHS/REACH directives. For regulated industries, confirm traceability protocols and batch-level documentation. Utilize secure transaction mechanisms where available, ensuring payment protection until sample approval. Response time (ideally ≤5 hours) and reorder rate (>50%) are strong indicators of customer satisfaction and service reliability.

What Are the Best Electronic Prototype Service Suppliers?

| Company Name | Location | Main Processes | Materials Supported | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Suzhou Engine Electronic Technology Co., Ltd. | Suzhou, CN | PCBA, Multilayer PCB, SMT | FR-4, Rogers, Aluminum Substrate | 91% | ≤3h | <15% | Color, size, logo, packaging, label | 1 unit |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangzhou, CN | CNC Machining, Vacuum Casting, 3D Printing | ABS, PC, Nylon, Rubber, Metal Alloys | 100% | ≤5h | 85% | N/A | 1 unit |

| Guangdong Fohan Technology Co., Ltd. | Guangdong, CN | 3D Printing, Casting, Moulding | PLA, ABS, Resin, Nylon, Silicone | 86% | ≤8h | 60% | N/A | 1 piece |

| Shenzhen Yuhan Precision Technology Co., Ltd. | Shenzhen, CN | 3D Printing, Silicone Molding, Vacuum Casting | PU, ABS, PC, Silicone, Urethane | 100% | ≤1h | 50% | Color, material, size, logo, packaging, graphic | 1 piece |

| Shenzhen JVi Prototype Co.,Ltd | Shenzhen, CN | 3D Printing (SLA/SLS/FDM), Metal Prototyping | Nylon, PLA, Metal Alloys, Engineering Plastics | 83% | ≤4h | 25% | N/A | 1 piece |

Performance Analysis

Guangzhou Gaojie and Shenzhen Yuhan stand out with 100% on-time delivery records and high reorder rates (85% and 50%, respectively), indicating strong customer retention and process consistency. Shenzhen Yuhan excels in responsiveness (≤1 hour average reply time) and offers extensive customization across multiple parameters, making it ideal for iterative design projects. Suzhou Engine specializes in high-reliability PCBA and multilayer PCB prototyping, catering to industrial and communication applications requiring strict electrical performance. While Shenzhen JVi provides broad material options and metal prototyping, its lower reorder rate suggests room for improvement in post-sale engagement. Buyers seeking full enclosure + electronics integration should prioritize suppliers like Guangdong Fohan and Guangzhou Gaojie that combine 3D printing with secondary finishing and assembly.

FAQs

How to verify electronic prototype supplier reliability?

Review certifications (ISO 9001, RoHS), request process capability data (Cpk values for critical dimensions), and validate technical competence through sample evaluations. Analyze response patterns, order history, and repeat purchase metrics as proxies for service quality and dependability.

What is the typical lead time for electronic prototypes?

Standard PCB prototypes take 3–5 days; complex multilayer boards require 7–10 days. 3D-printed enclosures or machined parts typically ship within 5–7 days. Vacuum-cast or urethane prototypes with tooling take 7–12 days depending on part complexity and finishing requirements.

Do suppliers support full turnkey prototyping?

Yes, leading providers offer end-to-end services including bill-of-materials procurement, SMT assembly, hand soldering, programming, functional testing, and final packaging. Confirm availability of component sourcing for legacy or long-lead items before project initiation.

What are common customization options?

Available customizations include color tinting, surface finishes (gloss/matte/textured), laser engraving, embedded logos, overmolding, and packaging configuration. For electronics, options extend to firmware loading, labeling, and ESD-safe packaging.

Can I request samples before mass production?

All listed suppliers accommodate single-unit orders for prototype validation. Sample costs are typically non-refundable but may be credited toward future production runs. Expect unit prices to reflect low-volume processing; economies of scale apply at batches exceeding 100 units.