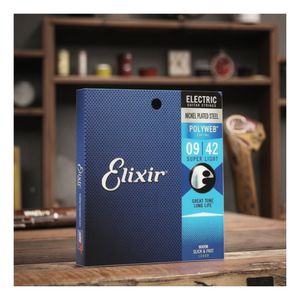

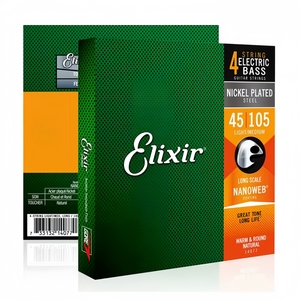

Elixir Strings Acoustic

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/19

1/19

1/2

1/2

1/16

1/16

1/17

1/17

1/3

1/3

1/15

1/15

0

0

0

0

1/3

1/3

1/19

1/19

1/3

1/3

0

0

0

0

1/3

1/3

1/2

1/2

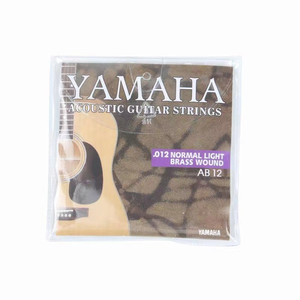

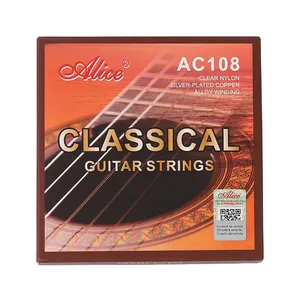

About elixir strings acoustic

Where to Find Elixir Strings Acoustic Suppliers?

China serves as a central hub for the production of acoustic guitar strings, including those designed to meet the performance standards associated with premium brands like Elixir. Key manufacturing clusters are located in Guangdong, Hunan, and Sichuan provinces, where vertically integrated supply chains support efficient raw material processing, coating technologies, and precision winding techniques. These regions host specialized facilities focused on phosphor bronze, 80/20 bronze, and stainless steel string formulations—materials critical for tone clarity, corrosion resistance, and extended lifespan.

The industrial ecosystems in cities such as Guangzhou, Changsha, and Chengdu enable tight coordination between wire drawing, core-to-wrap assembly, polymer coating (e.g., nanoweb or polyweb equivalents), and packaging operations. This integration allows suppliers to maintain consistent tension calibration and finish uniformity across batches. Buyers benefit from scalable production capacities, with leading factories reporting monthly outputs exceeding 100,000 sets. Average lead times range from 15–30 days for bulk orders, while localized logistics networks ensure rapid dispatch via air or sea freight to international markets.

How to Choose Elixir Strings Acoustic Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Material & Process Compliance

Verify use of high-purity alloys—phosphor bronze (CuSn6) or 80/20 bronze (CuZn20)—for wound strings, and tin-plated or nickel-plated steel for plain strings. Coated strings should utilize proprietary polymer films applied through controlled-environment processes to prevent micro-abrasions. Request spectrographic analysis reports for alloy composition and adhesion testing data for coatings. ISO 9001 certification is recommended as a baseline quality management standard.

Production Capability Assessment

Evaluate supplier infrastructure based on the following criteria:

- Minimum factory area of 2,000m² dedicated to string manufacturing

- In-house winding machines capable of handling gauges from .010" to .056"

- Controlled humidity and temperature environments for coating application

- Dedicated QC stations with tensile strength testers and optical inspection systems

Cross-reference online revenue metrics and on-time delivery rates (target ≥95%) to assess operational stability.

Procurement Safeguards

Utilize secure payment mechanisms such as trade assurance or escrow services until product acceptance. Prioritize suppliers offering sample validation programs with clear return policies. Conduct pre-shipment inspections using third-party auditors when ordering above 1,000 units. Confirm packaging compatibility with export conditions, especially for moisture-sensitive coated strings.

What Are the Best Elixir Strings Acoustic Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order Quantity | Customization | Product Range |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Vines Music Instruments Co., Ltd. | Guangdong, CN | US $620,000+ | 97% | ≤4h | <15% | 10–100 pieces | OEM logo, packaging, gauge | Broad |

| Changsha Geake Music Co., Ltd. | Hunan, CN | US $180,000+ | 95% | ≤1h | <15% | 10 pieces | Limited | Moderate |

| Chengdu Jile Culture Communication Co., Ltd. | Sichuan, CN | US $20,000+ | 92% | ≤3h | <15% | 2 pieces | No | Narrow |

| Shenzhen Guitary Technology Co., Ltd. | Guangdong, CN | US $10,000+ | 90% | ≤4h | <15% | 10 pieces | No | Broad |

| Guangzhou Yida Musical Instrument Co., Ltd. | Guangdong, CN | US $10,000+ | 100% | ≤5h | 50% | 10–200 sets | No | Wide |

Performance Analysis

Guangzhou Vines leads in customization capability and verified sales volume, supporting OEM branding and tailored packaging—ideal for private-label distributors. Changsha Geake stands out for responsiveness (≤1h average reply time) and high transaction reliability, though its reorder rate suggests limited customer retention beyond initial procurement. Guangzhou Yida demonstrates strong repeat business (50% reorder rate), indicating consistent product satisfaction despite higher MOQs. Chengdu Jile offers the lowest entry threshold (MOQ: 2 pieces), suitable for small retailers or sampling. Shenzhen Guitary provides diverse material options, including stainless steel and phosphor bronze variants, enhancing flexibility for niche market demands.

FAQs

How to verify acoustic string supplier quality?

Request material certifications (e.g., RoHS, REACH) and process control documentation. Conduct independent lab tests for core wire diameter accuracy, breakage load, and coating integrity. Analyze customer feedback focusing on string longevity and tonal consistency after extended play.

What is the typical sampling timeline for guitar strings?

Standard samples ship within 5–7 days after order confirmation. Customized samples with branded packaging require 10–14 days. Air freight adds 3–6 days depending on destination region.

Can suppliers produce Elixir-style coated strings?

Yes, several manufacturers offer nano-coating or thin-film polymer treatments that mimic extended-life performance. Confirm coating method (dip-coating vs. plasma deposition), thickness (typically 0.0001–0.0003 inches), and abrasion resistance through peel and flex tests.

Do suppliers support private labeling and custom packaging?

Selected manufacturers like Guangzhou Vines provide full OEM services, including custom box design, logo printing, and multi-language labeling. Minimum branding quantities typically start at 100 units per SKU.

What are common MOQs and pricing benchmarks?

MOQs vary from 2 pieces for retail-ready packs to 100–200 sets for wholesale contracts. Unit prices range from $0.25 to $5.00 depending on material grade, coating type, and packaging complexity. Phosphor bronze sets typically cost 15–25% more than 80/20 bronze equivalents.