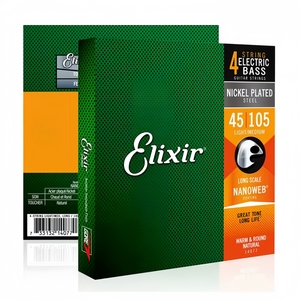

Elixir Strings Producer

CN

CN

About elixir strings producer

Where to Find Elixir Strings Producers?

China's musical instrument components sector features a specialized network of manufacturers producing high-tension, corrosion-resistant strings using advanced wire-drawing and coating technologies. Key production clusters are located in Guangdong, Sichuan, and Guizhou provinces, where vertically integrated facilities support end-to-end manufacturing—from raw steel and nylon filament sourcing to precision winding and polymer coating. These regions benefit from established supply chains for nickel-plated alloys, phosphor bronze, and synthetic core materials, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian producers.

Suppliers in this ecosystem typically operate dedicated production lines for electric, acoustic, and classical guitar strings, with process automation ensuring consistent tension calibration and diameter tolerance (±0.01mm). The presence of localized material suppliers and packaging partners within 50km radii reduces lead times and enhances responsiveness. Buyers gain access to scalable output capacities, with top-tier factories reporting monthly string set productions exceeding 500,000 units. This infrastructure supports both bulk fulfillment and low-volume custom orders with minimal setup delays.

How to Choose Elixir Strings Producers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Production Capabilities

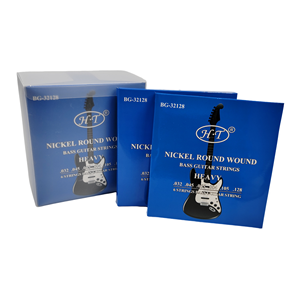

Confirm ownership of in-house drawing, winding, and coating equipment. Suppliers advertising "own production line" status typically maintain tighter control over material purity and layer uniformity—critical factors in extending string lifespan. Prioritize companies with documented R&D activities in nanocoating or fatigue-resistant alloys, as these indicate long-term performance innovation.

Quality Assurance Metrics

Evaluate operational KPIs derived from transactional data:

- On-time delivery rates ≥97% indicate reliable logistics planning

- Response times ≤3 hours reflect active order management capacity

- Reorder rates below 25% suggest room for service improvement, though not necessarily product deficiency

While formal certifications like ISO 9001 or RoHS compliance are not explicitly listed in available profiles, consistent online revenue generation (e.g., >US $100,000 annually) implies adherence to baseline quality and export standards required by international buyers.

Customization & Transaction Security

Assess flexibility in gauge specifications, core-to-winding ratios, packaging design, and private labeling. Multiple suppliers in the dataset offer OEM/ODM services, including logo imprinting and bespoke tension configurations. For risk mitigation, initiate transactions through secured payment channels and request physical samples before scaling volume. Validate coating durability via salt spray testing or accelerated aging protocols if longevity claims are central to procurement criteria.

What Are the Leading Elixir Strings Producers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Zunyi Talent Scout Musical Instruments Co., Ltd. | Guitar, Classical Nylon, Acoustic Steel | US $1,200,000+ | 100% | ≤2h | 25% | Cable type, color, logo, model | 1 piece |

| Zijin Kongyuen Musical Instrument Co., Ltd. | Steel Wire, OEM Classical, High-Carbon Sets | US $110,000+ | 100% | ≤2h | <15% | Color, packaging, label, material specs | 1 set |

| Guangzhou Vines Music Instruments Co., Ltd. | Electric Guitar OEM, PVD-Coated Strings | US $350,000+ | 97% | ≤3h | <15% | Material, thickness, logo, dimensions | 1 set |

| Chengdu Jile Culture Communication Co., Ltd. | Steel Singles, Nickel-Plated, Nylon Sets | US $20,000+ | 96% | ≤3h | <15% | Limited (product-specific) | 2 boxes/pieces |

| Changshu Huasheng Musical Instrument Co., Ltd. | Guitar, Mandolin, Accessories | US $40,000+ | 96% | ≤5h | 23% | Logo, style, graphic options | 100 pieces |

Performance Analysis

Zunyi Talent Scout leads in scalability and responsiveness, combining 100% on-time delivery with the lowest MOQs (as low as one piece), making it suitable for test batches and niche market launches. Zijin Kongyuen and Guangzhou Vines demonstrate strong technical adaptability, offering granular customization in material composition and dimensional tolerances—ideal for brands developing proprietary string formulations. Chengdu Jile, while smaller in revenue scale, maintains a focused portfolio aligned with standard retail pack formats. Changshu Huasheng provides broader accessory integration but imposes higher minimums, better suited for consolidated orders. Suppliers with reorder rates under 15% may prioritize new client acquisition over retention, warranting closer scrutiny of after-sales service structures.

FAQs

Do elixir strings producers offer sample batches?

Yes, most suppliers provide samples, often at nominal cost. Pricing ranges from $0.36 to $6 per unit depending on material and finish. Some waive fees for subsequent bulk orders. Sample lead times average 7–14 days, excluding shipping.

What is the typical MOQ for coated guitar strings?

Minimum order quantities vary: single-piece sampling is available from select vendors, while standard production runs start at 10–100 sets. Bulk pricing applies at 20+ sets, with optimal economies achieved at 100+ units.

Can manufacturers replicate specific tonal characteristics?

Yes, through adjustable parameters such as winding density, alloy mix (e.g., nickel vs. stainless steel), and core hex-vs-round geometry. Suppliers with dedicated R&D teams can simulate target frequency response curves upon request.

Are private label and packaging customization available?

Widely offered. Customization includes branded packaging, UPC coding, hang tags, and colored wrappers. Logo application is supported via printing, engraving, or adhesive labels, with digital proofing provided pre-production.

What are common lead times after order confirmation?

Standard orders ship within 15–25 days. Custom formulations or tooling adjustments may extend timelines to 35 days. Air freight delivers samples in 5–10 days internationally; sea freight takes 25–40 days depending on destination port congestion.