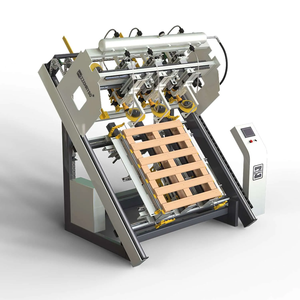

Stringer Machine Producer

1/3

1/3

0

0

1/3

1/3

0

0

1/32

1/32

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/25

1/25

1/8

1/8

1/3

1/3

1/22

1/22

0

0

0

0

1/14

1/14

1/3

1/3

1/3

1/3

About stringer machine producer

Where to Find Stringer Machine Producers?

China remains the central hub for stringer machine manufacturing, with key production clusters concentrated in Guangdong and Anhui provinces. These regions host specialized sports equipment manufacturers that integrate design, engineering, and assembly under one roof. Shenzhen-based producers leverage proximity to component suppliers and export ports, enabling rapid prototyping and efficient logistics. Meanwhile, Anhui’s industrial ecosystem supports cost-effective manual and electric stringer production, particularly for mid-range consumer and commercial-grade models.

The clustering effect facilitates vertically integrated supply chains—spanning motor sourcing, frame fabrication, and electronic tension control systems—within a 50-kilometer radius. This integration reduces lead times to 20–35 days for standard orders and allows flexible MOQs as low as one set. Buyers benefit from 15–25% lower unit costs compared to Western or Southeast Asian alternatives, driven by localized sourcing of steel frames, clamping mechanisms, and digital force sensors.

How to Choose Stringer Machine Producers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Standards

Verify adherence to international quality benchmarks such as ISO 9001. While not all suppliers list CE or RoHS certifications, these are essential for compliance in European and North American markets. Request documentation on calibration accuracy (±1% tension deviation), durability testing (minimum 10,000 cycles), and material specifications (e.g., aluminum alloy frames, reinforced polymer bases).

Production Capability Assessment

Evaluate infrastructure indicators:

- Facility size exceeding 3,000m² indicates capacity for batch production

- In-house R&D teams support customization of tension range (20–70 lbs), mounting systems, and motor integration

- Presence of CNC machining and welding stations confirms vertical integration

Cross-reference on-time delivery rates (>95%) and response times (<6 hours) as proxies for operational reliability.

Procurement Safeguards

Utilize secure payment methods with escrow functionality to mitigate risk. Prioritize suppliers offering sample units for performance validation. Conduct virtual factory audits to confirm production lines and quality inspection processes. Insist on post-delivery support, including spare parts availability and technical guidance for setup.

What Are the Leading Stringer Machine Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Gelinshi Sport Equipment Co., Ltd. | Guangdong, CN | Tennis & Badminton Stringers, Training Equipment | US $70,000+ | 94% | ≤6h | <15% | Not specified | 1 set |

| Shenzhen Konmat Sports Technology Co., Ltd. | Guangdong, CN | Manual Stringing Machines, Pickleball Gear | US $20,000+ | 100% | ≤1h | <15% | OEM/ODM supported | 1 set |

| Dongguan SIBOASI Sports Goods Technology Co., Ltd. | Guangdong, CN | High-End Electric Stringers, Training Tools | US $10,000+ | 100% | ≤3h | <15% | Not specified | 1 piece |

| Anhui Lingmei Sporting Goods Co., Ltd. | Anhui, CN | Computerized & Manual Stringers | US $380,000+ | 98% | ≤3h | <15% | Color, size, logo, packaging | 1 piece/set |

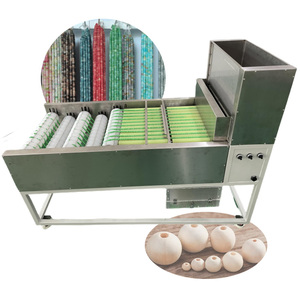

| CQ MECHANICAL TECHNOLOGY INC | Chongqing, CN | Meat Skewer/String Machines (Non-sports) | Data unavailable | No data | ≤1h | No data | Not applicable | 1 set |

Performance Analysis

Shenzhen Konmat and Dongguan SIBOASI demonstrate perfect on-time delivery records, indicating robust production planning. Anhui Lingmei stands out with the highest reported online revenue (US $380,000+), suggesting strong market penetration and repeat buyer engagement. Its customization capabilities—including color, branding, and packaging—make it a strategic partner for private-label brands. Shenzhen-based firms offer faster communication (response ≤1h to ≤6h), critical for time-sensitive procurement cycles. Notably, CQ Mechanical Technology appears misclassified, listing meat skewering machines rather than racquet stringers—highlighting the need for product verification during supplier screening.

FAQs

How to verify stringer machine producer reliability?

Cross-check self-reported metrics with transaction histories and customer reviews. Request evidence of quality control processes, such as tension calibration logs and material test reports. Conduct video audits to validate factory operations and inventory levels.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Custom configurations involving digital displays or enhanced tension ranges may require 20–25 days. Air freight adds 5–10 days for international delivery.

Can stringer machine producers ship globally?

Yes, most established manufacturers offer FOB and CIF shipping terms. Confirm packaging standards (wooden crates recommended for electric models) and ensure compliance with destination electrical safety regulations (e.g., UL listing for U.S. imports).

Do suppliers provide free samples?

Free samples are rare. Most charge full or partial fees, refundable upon placement of bulk orders (typically 5+ units). Sample costs range from $400–$2,300 depending on automation level.

How to initiate customization requests?

Submit detailed specifications: desired tension range, frame compatibility (tennis, badminton, pickleball), power source (manual, electric, battery-operated), and branding elements. Leading producers like Anhui Lingmei offer 3D mockups within 48 hours and prototype development in 2–3 weeks.