Yonex Stringing Machine Producer

About yonex stringing machine producer

Where to Find Yonex Stringing Machine Producers?

China serves as the central hub for racket stringing machine manufacturing, with key production clusters in Guangdong and Fujian provinces. Dongguan and Shenzhen in Guangdong are home to specialized sports equipment manufacturers offering vertically integrated production lines capable of delivering both manual and computerized stringing systems. These regions benefit from proximity to component suppliers for precision motors, tensioning mechanisms, and control panels, reducing lead times by 20–30% compared to offshore alternatives.

Manufacturers in these zones operate dedicated facilities equipped for OEM/ODM production, supporting full-cycle development from design to final assembly. The ecosystem enables rapid prototyping and scalable output, with select suppliers reporting monthly production capacities exceeding 500 units. Integration with local logistics networks ensures efficient export processing, particularly for buyers sourcing high-volume or customized configurations for tennis, badminton, and pickleball rackets.

How to Choose Yonex Stringing Machine Producers?

Procurement decisions should be guided by technical capability, quality assurance, and transactional reliability:

Production Infrastructure Verification

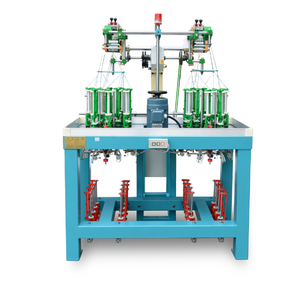

Prioritize suppliers with in-house engineering teams and CNC machining capabilities to ensure precision in critical components such as clamps, turntables, and motorized tensioners. Confirm ownership of automated assembly lines—particularly for electronic calibration systems—as a marker of scalability and consistency. Facility size should exceed 3,000m² for suppliers targeting bulk orders.

Quality & Compliance Standards

While formal certifications (ISO 9001, CE) are not universally declared in available data, assess compliance through documented testing protocols for tension accuracy (±0.5 lbs tolerance), durability under continuous operation, and electrical safety standards. Request calibration certificates and software validation reports for digital models.

Customization and Transaction Metrics

Evaluate customization depth: leading producers support modifications in color, branding (logo/packaging), material finishes, and software interface localization. Use response time (≤5 hours is standard; top performers respond in ≤1 hour) and on-time delivery rates (>95%) as proxies for operational discipline. Suppliers with online revenue exceeding US $200,000 demonstrate established export activity and customer trust.

What Are the Leading Yonex Stringing Machine Producers?

| Company Name | Location | Verified Type | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Key Offerings |

|---|---|---|---|---|---|---|---|

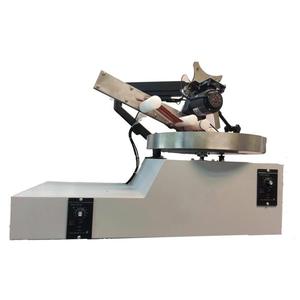

| Dongguan Siboasi Sports Goods Technology Co., Ltd. | Dongguan, CN | Custom Manufacturer | 95% | ≤5h | <15% | US $60,000+ | Automatic stringing machines; OEM/ODM services; full graphic customization |

| Shenzhen Konmat Sports Technology Co., Ltd. | Shenzhen, CN | - | 100% | ≤1h | <15% | US $20,000+ | Manual vertical stringing machines; direct factory pricing; low MOQ options |

| LIBOTAI International Co Ltd | Taiwan, CN | - | 94% | ≤5h | 66% | US $30,000+ | Vertical multi-sport machines; broad product range including rackets and nets |

| Dongguan Strong Machinery Equipment Co., Ltd | Dongguan, CN | Multispecialty Supplier | 100% | ≤3h | <15% | US $200,000+ | Manual and automatic models; high-volume production; customization options |

| Yixing Boyu Electric Power Machinery Co., Ltd. | Jiangsu, CN | - | 100% | ≤11h | 75% | US $580,000+ | Industrial-grade hydraulic tensioning systems; large-scale machinery focus |

Performance Analysis

Dongguan-based Siboasi and Strong Machinery represent core producers of consumer-grade stringing equipment, offering automation and customization at competitive price points ($1,462–$2,286). Shenzhen Konmat stands out for responsiveness (≤1h) and cost efficiency, with manual models starting at $414.60 per set. LIBOTAI’s 66% reorder rate indicates strong customer retention, likely driven by diversified product offerings beyond stringing machines. Notably, Yixing Boyu reports the highest online revenue (US $580,000+), though its product listings align more closely with industrial cable tensioning systems than sport-specific stringing units—procurement teams should verify application compatibility before engagement.

FAQs

Do Yonex stringing machine producers offer OEM/ODM services?

Yes, multiple suppliers—including Dongguan Siboasi and Shenzhen Konmat—explicitly list OEM/ODM capabilities. Customization includes logo imprinting, packaging design, color variation, and software interface adjustments. Minimum order quantities typically start at 1 unit for prototypes and 10–12 units for batch production.

What are typical MOQ and pricing ranges?

MOQs vary by model and automation level. Manual stringing machines start at $400–$450 with MOQs of 1–10 sets. Automated systems range from $1,500 to $2,300, with most suppliers requiring only 1 unit as minimum order. Industrial-grade tensioning equipment exceeds $50,000 with 1-set orders.

What is the average lead time for production and shipping?

Standard production lead time is 15–25 days after order confirmation. Air freight delivery to North America or Europe takes 5–10 days; sea freight requires 25–35 days. Expedited production (7–10 days) may be available for urgent requests, subject to supplier capacity.

Are samples available for testing?

Most suppliers allow sample orders. Pricing for samples reflects full unit cost, though some deduct this amount from future bulk orders. Buyers are advised to conduct functional testing on tension accuracy, clamp stability, and software responsiveness before scaling procurement.

How to validate technical specifications before purchase?

Request detailed product manuals, calibration procedures, and video demonstrations of machine operation. For automated models, confirm software compatibility (Windows/Linux), update frequency, and technical support availability. Conduct virtual factory audits to observe assembly processes and quality checks.