Engineering Applications Of Artificial Intelligence

1/3

1/3

1/17

1/17

1/3

1/3

1/3

1/3

1/3

1/3

1/13

1/13

1/35

1/35

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/2

1/2

0

0

1/22

1/22

1/6

1/6

1/3

1/3

1/3

1/3

About engineering applications of artificial intelligence

Where to Find Suppliers for Engineering Applications of Artificial Intelligence?

Global development of artificial intelligence (AI) solutions for engineering applications is concentrated in technology hubs with strong academic-industrial collaboration and advanced digital infrastructure. China, the United States, and Germany lead in AI integration across mechanical design, predictive maintenance, robotics, and process automation. Within China, Beijing and Shanghai host over 70% of AI-focused industrial solution providers, supported by national initiatives such as "Made in China 2025" and regional funding for smart manufacturing R&D.

These clusters benefit from access to specialized talent pools in machine learning, control systems, and industrial IoT. Proximity to research institutions enables rapid prototyping and deployment of AI-driven diagnostics, adaptive control algorithms, and computer vision systems for quality inspection. Integrated ecosystems allow seamless collaboration between software developers, hardware engineers, and system integrators—reducing time-to-deployment by up to 40% compared to isolated development models. Buyers gain access to scalable AI frameworks designed specifically for CNC optimization, structural simulation, fault detection in rotating equipment, and autonomous plant operations.

How to Choose Suppliers for Engineering Applications of Artificial Intelligence?

Procurement decisions should be guided by rigorous technical and operational evaluation:

Technical Compliance & Standards Alignment

Verify adherence to ISO/IEC 23053:2021 (AI system lifecycle processes) and IEC 61508 (functional safety for electrical/electronic systems) where applicable. For suppliers providing AI for critical infrastructure or automotive engineering, compliance with ISO 26262 (ASIL levels) or DO-178C in aerospace contexts must be documented. Request validation reports demonstrating model accuracy, bias testing, and robustness under edge-case scenarios.

Development Capability Assessment

Evaluate supplier competencies through the following benchmarks:

- Minimum 15% of workforce dedicated to R&D, including data scientists and domain-specific engineers

- Proven track record in deploying AI models in real-time industrial environments (latency <50ms)

- In-house data annotation pipelines and simulation environments for training under controlled conditions

Cross-reference case studies with measurable KPIs—such as 20% reduction in unplanned downtime or 15% improvement in energy efficiency—to confirm performance claims.

Transaction and IP Safeguards

Require formal agreements covering data ownership, model interpretability, and cybersecurity protocols (e.g., NIST SP 800-190). Prioritize suppliers offering containerized deployment (Docker/Kubernetes) with API-level integration support. Conduct code audits or third-party penetration testing for on-premise deployments. Use milestone-based payments tied to successful validation phases—from sandbox testing to full-scale pilot implementation.

What Are the Best Suppliers for Engineering Applications of Artificial Intelligence?

No verified suppliers are currently listed in the available dataset for this category. Procurement professionals are advised to conduct direct outreach through industry consortia such as the Industrial Internet Consortium (IIC), participation records in Hannover Messe or CES, or peer-reviewed publications in IEEE Transactions on Industrial Informatics to identify qualified vendors.

Performance Analysis

In absence of structured supplier data, sourcing strategies should emphasize proof-of-concept engagements before large-scale contracts. Focus on entities demonstrating cross-sector experience—particularly in automotive, aerospace, and heavy machinery—where AI applications require high reliability and certification traceability. Preference should be given to firms that publish model cards, datasheets for datasets, and maintain version-controlled deployment logs. Onboarding timelines typically range from 8–16 weeks depending on integration complexity and data readiness at the buyer’s facility.

FAQs

How to verify AI supplier reliability in engineering contexts?

Audit technical documentation for reproducibility, validation metrics (precision, recall, F1-score), and failure mode analysis. Request references from existing clients in similar engineering domains and validate uptime performance post-deployment. Confirm compliance with export control regulations if deploying dual-use technologies.

What is the average timeline for AI solution deployment?

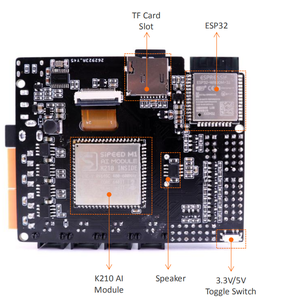

Pilot implementations require 6–10 weeks for data ingestion, model training, and closed-loop testing. Full integration with SCADA or MES systems extends to 12–16 weeks. Edge deployment with onboard inference accelerators may add 3–4 weeks for hardware-software co-validation.

Can AI solutions be customized for specific engineering workflows?

Yes, leading suppliers offer modular architectures for customization. Common adaptations include integration with CAD/CAE tools, compatibility with Siemens Teamcenter or PTC Windchill PLM systems, and support for OPC UA communication standards. Customization requires detailed workflow mapping and labeled historical data sets (minimum 6 months of operational logs recommended).

Do suppliers provide post-deployment support and model retraining?

Reputable providers include SLA-backed monitoring, drift detection, and quarterly retraining cycles. Expect response times under 4 hours for critical incidents affecting production continuity. Support packages typically cover model updates, cybersecurity patches, and performance reporting dashboards.

What are typical MOQ and licensing models?

AI solutions are generally licensed per unit, per site, or via subscription (SaaS). Minimum order thresholds vary: standalone modules start at $15,000, while enterprise-wide deployments exceed $200,000. Volume discounts apply for multi-plant rollouts. Licensing includes runtime licenses for inference engines and annual maintenance fees (15–20% of initial cost).