Example Of Smart Factory

Top sponsor listing

Top sponsor listing

CN

CN

About example of smart factory

Where to Find Smart Factory Solution Suppliers?

China remains a central hub for smart factory technology and automation systems, with key suppliers concentrated in industrial zones across Guangdong, Zhejiang, and Shandong provinces. These regions host integrated manufacturing ecosystems that combine electronics production, industrial IoT development, and automated machinery engineering. The Pearl River Delta, particularly Shenzhen and Dongguan, excels in smart wearables and PCB assembly integration, while Ningbo and Jinan specialize in intelligent woodworking and access control automation systems.

Suppliers in these clusters benefit from proximity to component manufacturers, logistics networks, and technical talent pools, enabling rapid prototyping and scalable production. Buyers gain access to vertically aligned supply chains capable of delivering end-to-end smart factory subsystems—from sensor networks to automated production lines—within compressed lead times. Typical advantages include 20–35% cost efficiency over Western counterparts, modular customization options, and established export channels to Europe, North America, and Southeast Asia.

How to Choose Smart Factory Technology Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Integration Capability

Verify adherence to international standards such as ISO 9001 for quality management and CE marking for electrical safety. For IoT-enabled devices, confirm compatibility with common industrial protocols (e.g., Modbus, OPC UA) and cybersecurity measures for data transmission. Suppliers offering PCBA or smart wearable solutions should provide test reports for signal integrity, power efficiency, and environmental durability.

Production Capacity and R&D Infrastructure

Assess core capabilities through the following indicators:

- Facility size exceeding 3,000m² for sustained volume output

- In-house SMT/DIP assembly lines for electronic components

- Dedicated R&D teams supporting firmware updates and hardware customization

Cross-reference on-time delivery rates (target ≥98%) and response times (ideally ≤4 hours) as proxies for operational reliability.

Customization and Transaction Security

Prioritize suppliers with documented OEM/ODM experience, including logo printing, packaging design, and functional modifications. Use secure payment mechanisms such as escrow services, especially when engaging newer suppliers without long-term transaction histories. Request pre-shipment product samples to validate build quality, software functionality, and compliance with specified performance metrics.

What Are the Leading Smart Factory Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Verification Status |

|---|---|---|---|---|---|---|

| Ningbo Doortec Automatic Door Co., Ltd. | Automatic Door Operators, Gate Systems, Access Control Sensors | 98% | ≤4h | 29% | US $260,000+ | Custom Manufacturer |

| Hunan Dark Horse Tongda Supply Chain Management Co., Ltd. | Smartwatches, Gift Sets, Custom Packaging Solutions | 100% | ≤2h | 40% | - | Not Specified |

| Huizhou Yungu Intelligent Technology Co., Ltd. | PCBA, OEM Circuit Board Assembly, Smart Electronics Prototyping | 100% | ≤2h | - | - | Not Specified |

| Guangdong Eternity Electronics Co., Ltd. | Smart Watches, Smart Glasses, Wearable AI Devices | 100% | ≤2h | <15% | US $20,000+ | Not Specified |

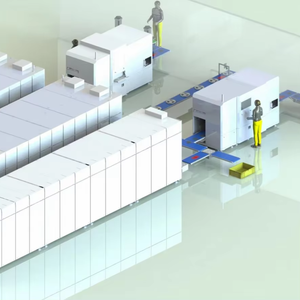

| Jinan Singhui CNC Technology Co., Ltd. | Smart Woodworking Factories, Automated Panel Production Lines | 100% | ≤10h | - | - | Custom Manufacturer |

Performance Analysis

Suppliers like Hunan Dark Horse Tongda and Huizhou Yungu demonstrate high responsiveness and perfect on-time delivery records, making them suitable for time-sensitive procurement cycles. Ningbo Doortec stands out in physical access automation with strong reorder rates and verifiable revenue, indicating market acceptance. Guangdong Eternity Electronics offers specialized smart wearable solutions but exhibits a low reorder rate, suggesting potential gaps in post-sale support or product consistency. Jinan Singhui targets capital-intensive smart factory installations, with equipment priced from $18,000 to $250,000 per system, reflecting advanced integration capabilities for industrial clients.

FAQs

How to verify smart factory supplier reliability?

Validate certifications (ISO, CE) through official registries and request audit trails for production processes. Conduct virtual factory tours to assess equipment condition and workflow organization. Analyze customer reviews focusing on software stability, after-sales technical support, and system uptime performance.

What is the typical MOQ and lead time?

Minimum order quantities vary by product type: electronic assemblies (10–20 sets), smart wearables (3–50 pieces), and full automation lines (1 set). Lead times range from 15 days for PCBAs to 60 days for customized smart factory systems, depending on complexity and testing requirements.

Can suppliers support global shipping and customs clearance?

Yes, most suppliers have export experience and partner with freight forwarders to manage FOB or CIF shipments. Confirm inclusion of necessary documentation (commercial invoice, packing list, CE certificates) and compliance with destination regulations for electrical and connected devices.

Do suppliers offer free samples?

Sample policies differ: some waive fees for bulk orders (e.g., >100 units), while others charge 30–70% of unit cost. For high-value systems like automated production lines, suppliers may require partial payment for prototype validation.

How to initiate customization for smart factory components?

Submit detailed specifications including desired connectivity (Wi-Fi/Bluetooth/NB-IoT), power requirements, enclosure materials, and software features. Reputable suppliers will respond with technical feasibility assessments, 3D models, or circuit schematics within 3–5 business days.