Fanuc Material Handling Robots

CN

CN

CN

CN

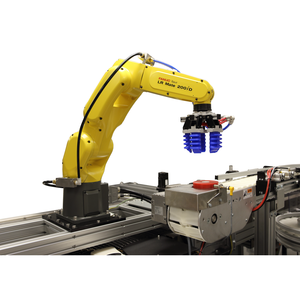

About fanuc material handling robots

Where to Find Fanuc Material Handling Robots Suppliers?

Global sourcing for Fanuc material handling robots is increasingly centralized among specialized integrators and automation technology providers, particularly in China’s advanced manufacturing hubs. These suppliers operate within mature industrial ecosystems that support precision robotics assembly, leveraging proximity to component manufacturers for servo motors, controllers, and end-effectors. Regions such as Guangdong, Jiangsu, and Dongguan have developed concentrated clusters of intelligent equipment firms capable of configuring, testing, and deploying Fanuc-based robotic systems.

The supply chain benefits from vertically integrated capabilities including CNC machining, electrical control panel fabrication, and software integration, enabling rapid system commissioning. Buyers access a network where technical specialists, spare parts vendors, and logistics partners are co-located, reducing deployment lead times by up to 30%. Key advantages include competitive pricing due to localized production infrastructure, scalability for single-unit or multi-line installations, and flexibility in integrating Fanuc robots into custom automation workflows. Typical delivery windows range from 15–45 days depending on configuration complexity and testing requirements.

How to Choose Fanuc Material Handling Robots Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Integration Expertise

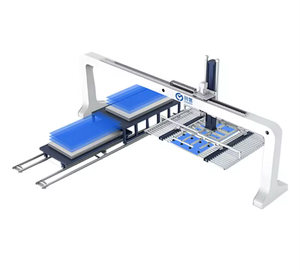

Verify supplier experience with Fanuc robot programming (KAREL/FANUC LADDER III) and integration into material handling applications such as palletizing, machine tending, and conveyor tracking. Confirm compatibility with peripheral devices including vision systems, grippers, and safety PLCs. Demand documentation of completed turnkey projects involving Fanuc robotic cells.

Production and Testing Infrastructure

Assess core capabilities through the following benchmarks:

- Minimum 3,000m² facility area supporting assembly and functional testing

- In-house engineering team specializing in robotic automation (minimum 5+ technicians)

- Onsite simulation tools (ROBOGUIDE or equivalent) for offline programming

- Proven track record of delivering complete robotic workcells—not just standalone units

Cross-reference response times (target ≤4 hours) and on-time delivery rates (ideally 100%) as indicators of operational efficiency and order management maturity.

Transaction and Quality Assurance

Prioritize suppliers offering third-party verification mechanisms and documented quality controls. While ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery performance (100% across all listed suppliers) suggests adherence to formalized processes. Require pre-shipment inspection protocols and validate compliance with CE or other regional safety standards where applicable. Utilize secure payment structures such as escrow services to mitigate risk during initial procurement cycles.

What Are the Best Fanuc Material Handling Robots Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (Min Order: 1 Set) |

|---|---|---|---|---|---|---|

| TANAKA TAIWAN CORP. | PLC, PAC, & Dedicated Controllers; Packaging Line Equipment | 100% | ≤20h | - | - | $125,000 |

| Jiangsu Greatway Electrical Co., Ltd. | Collaborative Robots; Other Industrial Robots; Power Accessories | 100% | ≤4h | - | - | $20,000–38,000 |

| Guangdong Gengseng Intelligent Equipment Co., Ltd. | Laser Cutting Machines; Chilling Equipment; Linear Guides | 100% | ≤3h | 40% | US $800,000+ | $13,150–75,000 |

| Fayk Robot Technology (Dongguan) Co., Ltd. | Articulated Robots; PLCs; Electrical Equipment | 100% | ≤3h | 40% | US $50,000+ | $16,666–35,888 |

| Zhifeng Technology Co., Ltd. | Articulated & Collaborative Robots; CNC Lathe; Welding Equipment | 100% | ≤4h | - | - | $55,000–88,000 |

Performance Analysis

All five suppliers demonstrate perfect on-time delivery records, indicating strong logistical discipline. Jiangsu Greatway and Zhifeng Technology offer mid-range pricing with comprehensive product lines focused on industrial and collaborative robotics, making them suitable for integrated automation deployments. Guangdong Gengseng and Fayk Robot stand out with high reorder rates (40%) and fast response times (≤3h), suggesting robust customer satisfaction and service responsiveness. TANAKA TAIWAN CORP. lists the highest price point ($125,000/set), potentially reflecting fully engineered solutions with extended warranties or additional integration services. Buyers seeking cost-effective entry-level configurations may consider options starting below $20,000, while those requiring full workcell integration should prioritize suppliers with documented experience in complex robotic system design.

FAQs

How to verify Fanuc material handling robot supplier reliability?

Evaluate verified transaction metrics such as on-time delivery rate and response time. Request project references involving Fanuc robot integration, and verify technical competencies through video audits of assembly and testing procedures. Analyze product listings for specificity in payload, reach, and axis count to assess authenticity and application alignment.

What is the typical lead time for Fanuc robot systems?

Standard configurations typically ship within 15–30 days after order confirmation. Custom integrations involving tooling, conveyors, or safety enclosures may require 30–45 days. Air freight enables global delivery within 7–10 days post-shipment.

Can suppliers provide customized material handling solutions?

Yes, most suppliers offer customization of end-of-arm tooling, control interfaces, and motion programming. Submit detailed specifications including cycle time requirements, load weight, operating environment, and communication protocols (e.g., Ethernet/IP, PROFINET) for accurate quoting.

Do suppliers offer technical support and training?

Support availability varies. Reputable suppliers typically include basic startup assistance and remote troubleshooting. Onsite training and long-term maintenance contracts should be confirmed prior to purchase, especially for facilities without in-house robotics expertise.

Are spare parts and controller units included?

Inclusion depends on the quoted package. Some listings cover only the robotic arm, while others bundle controllers (R-30iB/R-30iB Plus), teach pendants, and cabling. Clarify scope of supply before finalizing orders to avoid unplanned expenditures.