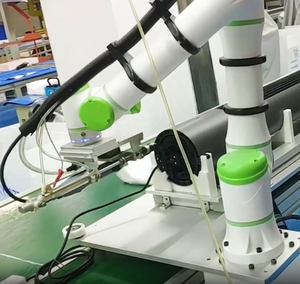

The First Material Handling Robot Employed In Industrial Production Work

About the first material handling robot employed in industrial production work

Where to Find Material Handling Robot Suppliers?

China leads global production of industrial material handling robots, with key manufacturing clusters in Guangdong and Shanghai offering specialized capabilities. Guangdong province hosts advanced robotics engineering firms leveraging Shenzhen’s innovation ecosystem and high-density automation supply chains. Shanghai-based suppliers integrate closely with Japan-originated robotic platforms such as Yaskawa, enabling access to proven motion control architectures and legacy system compatibility. These regions benefit from mature industrial automation infrastructure, including precision machining networks and embedded AI integration services.

The clustering effect supports vertically integrated development—from servo motor assembly to end-effector design—within localized ecosystems. This reduces component lead times by 25–40% compared to decentralized manufacturing models. Buyers gain access to scalable production capacities, with facilities capable of fulfilling single-unit pilot orders up to multi-unit production deployments. Average delivery cycles range from 30–60 days for standard configurations, with cost advantages of 20–35% over European or North American equivalents due to optimized labor and materials sourcing.

How to Choose Material Handling Robot Suppliers?

Implement the following evaluation criteria to ensure technical and operational reliability:

Technical Compliance & System Integration

Confirm adherence to international safety standards such as ISO 10218 (industrial robot systems) and ISO/TS 15066 (collaborative robotics). For deployment in EU or North American facilities, CE marking and risk assessment documentation are mandatory. Validate compatibility with existing PLCs, SCADA systems, and communication protocols (e.g., Modbus, PROFINET).

Production Capability Verification

Assess supplier infrastructure using these benchmarks:

- Minimum 50+ workforce with dedicated R&D or application engineering teams

- In-house testing rigs for cycle life, payload accuracy, and repeatability validation

- Access to calibration equipment for 6-axis kinematic alignment

Cross-reference on-time delivery rates (target ≥98%) and response times (ideally ≤2 hours) as indicators of operational maturity.

Transaction & Quality Assurance

Utilize secure payment mechanisms such as escrow services until post-delivery performance verification. Prioritize suppliers with documented quality management systems and third-party transaction validation. Pre-shipment inspection protocols should include functional testing under simulated load conditions. Request sample units for integration trials, particularly when automating critical production lines.

What Are the Best Material Handling Robot Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Notable Offerings |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Koza Robot Engineering Technology Co., Ltd. | Guangdong, CN | Articulated Robots (110), Collaborative Robots (78) | Not disclosed | 100% | ≤1h | - | Standard options | 6-axis collaborative and double-rotation models |

| Shanghai JSR Automation Co., Ltd | Shanghai, CN | Yaskawa-integrated handling robots, palletizers | US $1,000+ | 100% | ≤8h | <15% | Color, size, logo, packaging | Original Yaskawa GP180, AR1440, PL190 series |

| Shenzhen Guanhong Technology Co., Ltd. | Guangdong, CN | Articulated arms, welding robots | US $800,000+ | 98% | ≤2h | 26% | Color, size, logo, packaging | Payload range: 5–50kg; budget-oriented models |

| Ae Robotics Co., Ltd. | Not specified | Kawasaki-compatible 6-axis robots | US $40,000+ | 100% | ≤4h | 20% | Color, size, logo, packaging | RS020N (20kg), RS080N (80kg) payloads |

| Huiling-Tech Robotic Co., Ltd. | Not specified | SCARA, gantry, manipulators | US $20+ | 100% | ≤4h | <15% | Standard options | 4-axis SCARA arms, grippers, dishwasher robots |

Performance Analysis

Guangzhou Koza and Shenzhen Guanhong represent high-capacity engineering-focused suppliers, with Koza emphasizing 6-axis collaboration and Guanhong offering competitive pricing across diverse payload classes. Shanghai JSR distinguishes itself through integration with Yaskawa platforms—ideal for users requiring OEM-equivalent performance and service continuity. Ae Robotics provides access to Kawasaki-derived architectures, suitable for heavy-load applications exceeding 50kg. Huiling-Tech specializes in SCARA and gantry systems, catering to compact workspaces and repetitive pick-and-place workflows. On-time delivery is consistently strong across all five suppliers (all ≥98%), indicating reliable fulfillment discipline. However, reorder rates vary significantly, suggesting differences in long-term customer satisfaction and after-sales support effectiveness.

FAQs

How to verify material handling robot supplier reliability?

Validate technical claims through factory audit reports, video tours of assembly lines, and test certifications for safety and electromagnetic compatibility (EMC). Review transaction histories on business platforms for dispute resolution records and verified buyer feedback. Request references from clients in similar industries (e.g., automotive, electronics assembly).

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 unit, facilitating prototyping and pilot deployment. Standard lead times range from 30 to 60 days post-payment, depending on customization level. Expedited builds may be available at a premium for urgent integration timelines.

Can suppliers customize robots for specific production environments?

Yes, all listed suppliers offer customization options including color, labeling, and mechanical dimensions. Advanced modifications such as IP-rated enclosures, specialized end-effectors, or dual-arm configurations require direct engineering consultation and may extend lead times by 15–30 days.

Do suppliers provide software and programming support?

Basic programming interfaces and teach pendants are included. Some suppliers offer offline simulation setup or API access for PLC integration. For complex automation sequences, confirm availability of technical support engineers for on-site commissioning or remote debugging services.

Are spare parts and maintenance services available internationally?

Availability varies. Leading suppliers maintain overseas distribution channels or partner networks for critical components like reducers, controllers, and servo motors. Inquire about warranty terms (typically 12 months) and whether local service agents are present in your region to minimize downtime.