Finite Automaton

CN

CN

1/17

1/17

1/2

1/2

0

0

1/2

1/2

1/3

1/3

0

0

1/3

1/3

1/15

1/15

0

0

CN

CN

1/20

1/20

1/3

1/3

CN

CN

1/13

1/13

1/11

1/11

1/38

1/38

CN

CN

1/20

1/20

1/3

1/3

1/3

1/3

1/1

1/1

About finite automaton

Where to Find Finite Automaton Suppliers?

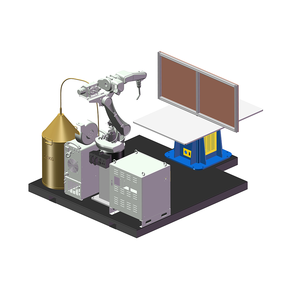

The global supply base for finite automaton systems—primarily hardware implementations or embedded modules used in industrial control, telecommunications, and automated testing—is concentrated in advanced electronics manufacturing hubs across East Asia, with China, Taiwan, and South Korea leading in production capacity. While not mass-produced as standalone machinery, specialized suppliers in Guangdong and Jiangsu provinces (China) dominate the ecosystem due to proximity to semiconductor foundries, PCB fabrication centers, and firmware development talent.

These regions support vertically integrated design-to-production workflows, enabling rapid prototyping and low-volume customization. Industrial clusters around Shenzhen and Suzhou offer access to SMT assembly lines, FPGA programming stations, and formal verification labs within tight geographic proximity. This integration reduces development lead times by 25–40% compared to decentralized sourcing models. Buyers benefit from scalable output ranging from research-grade single units to batch runs of 1,000+ modules per month, depending on complexity and certification requirements.

How to Choose Finite Automaton Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Compliance

Confirm adherence to ISO/IEC 9001 standards for design and development processes. For safety-critical applications (e.g., medical devices, rail signaling), IEC 61508 SIL-2 compliance or equivalent functional safety certification is essential. Request documentation of state transition validation, timing analysis, and fault tolerance testing where applicable.

Production Capability Audits

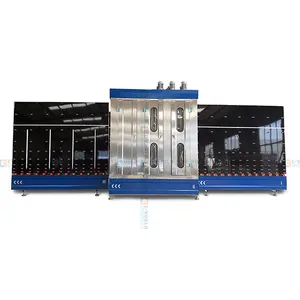

Evaluate supplier technical infrastructure:

- Minimum 2,000m² facility with ESD-protected assembly zones

- Dedicated R&D team experienced in formal methods and automata theory implementation

- In-house capabilities for FPGA configuration, microcontroller programming, and logic synthesis

Cross-reference project portfolios with delivery performance (target on-time completion rate >95%) to assess reliability in complex deployments.

Transaction Safeguards

Utilize milestone-based payment structures tied to prototype approval and test validation. Verify IP protection agreements prior to sharing state diagrams or transition logic specifications. Conduct sample evaluations using standardized input sequence benchmarks to confirm deterministic behavior before scaling procurement.

What Are the Best Finite Automaton Suppliers?

No verified suppliers are currently listed for dedicated finite automaton hardware or module production. The absence of structured supplier data suggests a fragmented market dominated by engineering firms offering custom digital logic solutions rather than off-the-shelf products. Procurement typically involves engaging electronic design service providers capable of translating theoretical automaton models into physical or programmable logic implementations.

Performance Analysis

In the absence of direct supplier listings, buyers should focus on firms with proven experience in deterministic system design, including PLC programming, lexical analyzer development, or protocol state machine implementation. Preference should be given to organizations publishing white papers on automata-based control systems, holding patents in digital logic optimization, or contributing to open-source formal verification tools. Geographic proximity to Tier-1 electronics manufacturing zones improves coordination efficiency during iterative debugging and firmware updates.

FAQs

How to verify finite automaton supplier reliability?

Review technical credentials such as IEEE membership, participation in formal methods conferences (e.g., CAV, TACAS), and publication history in automata theory applications. Validate past projects involving state machine realization through client references and code/logic walkthroughs. Audit quality management systems for traceability in design inputs, test cases, and version control.

What is the average sampling timeline?

Prototype development typically requires 20–35 days, depending on model complexity (e.g., DFA vs. NFA with ε-transitions). Simple Moore or Mealy machine implementations can be delivered in as few as 15 days using preconfigured FPGA platforms. Add 5–10 days for international shipping via express courier.

Can suppliers ship finite automaton systems worldwide?

Yes, most design houses support global delivery of embedded modules or programmed ICs. Confirm export compliance with local regulations, particularly for dual-use technologies involving encryption or real-time decision logic. Use FCA or DAP Incoterms for clarity on responsibility transfer during cross-border shipments.

Do manufacturers provide free samples?

Free samples are uncommon due to high design labor content. Suppliers may waive fees for qualified OEM clients committing to volume deployment (>500 units). Otherwise, expect prototype charges covering 40–70% of total development cost, refundable against future orders.

How to initiate customization requests?

Submit complete specifications including alphabet set, transition function table, initial/accept states, and desired output format (e.g., Verilog, VHDL, or microcontroller firmware). Reputable partners will return simulation results within 5 business days and functional prototypes within 4 weeks.