Flextronics Electronics Technology

Top sponsor listing

Top sponsor listing

CN

CN

About flextronics electronics technology

Where to Source Flextronics Electronics Technology Suppliers?

China remains the central hub for flextronics electronics technology manufacturing, with key production clusters concentrated in Guangdong, Jiangsu, and Shaanxi provinces. Shenzhen, a leading innovation center in Guangdong, hosts specialized firms focused on flexible printed circuit boards (FPCs), rigid-flex PCBs, and smart sensor integration. These suppliers benefit from proximity to semiconductor foundries, surface-mount technology (SMT) lines, and advanced prototyping facilities, enabling rapid iteration and low-volume customization.

The ecosystem supports vertically integrated production, where design, fabrication, assembly, and testing occur within tightly coordinated networks. Suppliers in this region typically offer turnkey solutions—from layout design to final product validation—with lead times averaging 10–20 days for sample batches and 25–35 days for mass production. Localized supply chains reduce component procurement delays, while access to skilled engineering talent supports complex multilayer and high-density interconnect (HDI) applications across wearable tech, medical devices, and industrial automation sectors.

How to Evaluate Flextronics Electronics Technology Suppliers?

Procurement decisions should be guided by structured assessment criteria to ensure technical reliability and supply chain resilience:

Technical Capability Verification

Confirm expertise in flexible circuit fabrication, including etching precision, bend radius tolerance (typically 0.5–1mm), and impedance control for high-speed signals. Prioritize suppliers offering multilayer FPCs (up to 8 layers), controlled-depth laser drilling, and coverlay lamination. For mission-critical applications, verify compatibility with RoHS, REACH, and IPC-6013 standards for flexible circuits.

Production Infrastructure Assessment

Evaluate operational scale and process control through the following indicators:

- Minimum monthly output capacity of 10,000 units for flexible PCBs

- In-house capabilities in photolithography, electroplating, and automated optical inspection (AOI)

- Dedicated SMT lines for component placement on flexible substrates

Cross-reference on-time delivery performance (target ≥95%) with response time (ideally ≤4 hours) to assess operational responsiveness.

Quality & Transaction Assurance

Require documented quality management systems such as ISO 9001. Analyze reorder rates (above 20% indicates strong customer retention) and fulfillment consistency. Use secure transaction mechanisms where payment is linked to verified delivery milestones. Pre-shipment inspections and sample validation are critical—test flex endurance over 5,000–10,000 bending cycles depending on application requirements.

What Are the Leading Flextronics Electronics Technology Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Product Examples |

|---|---|---|---|---|---|---|---|

| Shenzhen Smart Electronics Co., Ltd | Flex sensors, custom flex PCBs, bendable circuits | Size, material, graphic design | 100% | <15% | ≤2h | US $60,000+ | Smart flex sensor (2.2"), 4.5" bend sensor, customized flex boards |

| INTELLISENSE TECHNOLOGY | PCBA, rigid-flex PCBs, wearable electronics | Layer count, material specs, software integration | - | - | ≤4h | - | Multilayer custom PCB, ECG wearable PCB, power electronics development |

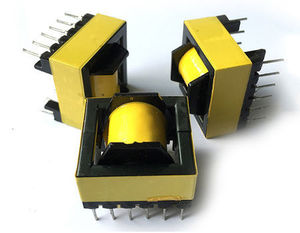

| Shaanxi Magason-Tech Electronics Co., Ltd. | Ferrite cores, electronic transformers, industrial components | Core color, wire diameter, number of turns, packaging | 95% | 18% | ≤6h | US $40,000+ | EFD10/12/15 transformers, EF20 ferrite core units |

| Suzhou Aolide Co., Ltd. | Printing plates, pre-press equipment, adhesive films | Color, material, size, logo, packaging, graphics | 100% | 20% | ≤4h | US $60,000+ | Industrial ultrasonic cleaners, plastic films, printing materials |

| Shenzhen ELINK Technology Co., Ltd. | FPCs, bendable circuit boards, PCB houses | Material, layer structure, graphic labeling | 33% | 33% | ≤2h | US $100+ | Flexible PCBs, single-layer domestic boards, Atmel-compatible FPCs |

Performance Analysis

Shenzhen-based suppliers demonstrate superior technical specialization in flexible electronics, with Smart Electronics offering fast turnaround and full customization for sensor-based applications. INTELLISENSE TECHNOLOGY leads in high-complexity rigid-flex PCBs used in wearables and sustainable energy systems, supported by extensive PCBA listings indicating mature production pipelines. While some suppliers like ELINK report lower on-time delivery rates (33%), their high reorder rate suggests niche demand or post-delivery satisfaction despite logistical inconsistencies. Buyers seeking volume stability should prioritize partners with proven delivery records (>95%) and robust online revenue histories.

FAQs

How to verify flextronics supplier technical compliance?

Request documentation on material specifications (e.g., polyimide base films, copper thickness), solder mask types, and thermal resistance ratings. Confirm adherence to IPC-2223 for flexible circuit design and UL certification for commercial deployment. Third-party lab reports on peel strength, flex durability, and dielectric performance provide additional validation.

What are typical MOQs and pricing ranges?

MOQs vary: prototypes start at 1–5 pieces ($0.20–$18/unit), while bulk orders begin at 100+ units with tiered pricing. Custom flex PCBs range from $0.50 to $3.50 per unit at volume. Sensors and integrated modules command higher prices ($5.80–$500) based on functionality and testing requirements.

Do suppliers support full customization?

Yes, most offer tailored solutions including dimensional adjustments, specific substrate materials (PI, PET), conductive ink types, shielding layers, and embedded components. Graphic labeling, branding, and packaging can also be customized. Engineering support is typically provided for layout optimization and DFM feedback.

What is the average sampling timeline?

Prototype development takes 7–14 days for simple flex circuits and up to 21 days for multilayer or hybrid assemblies. Add 5–10 days for international shipping via express carriers. Expedited services (3–5 days) are available at premium rates.

Can suppliers handle global logistics and export documentation?

Established manufacturers manage export procedures, including commercial invoicing, packing lists, and bill of lading. Most support FOB Shenzhen or CIF destination terms. Ensure compliance with import regulations regarding electronic components in target markets, particularly for products containing batteries or wireless modules.