Format Factory Format Factory

1/22

1/22

CN

CN

1/15

1/15

About format factory format factory

Where to Find Own Production Line Suppliers?

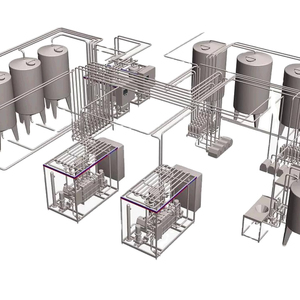

China remains the central hub for industrial production line manufacturing, with key supplier clusters concentrated in Henan and surrounding regions. These zones benefit from mature ecosystems integrating mechanical engineering, automation expertise, and metallurgical supply chains. Companies based in Zhengzhou and Yingkou demonstrate strong specialization across food processing, chemical manufacturing, metal fabrication, and electrical equipment assembly lines, enabling tailored solutions for diverse industrial applications.

The region’s competitive advantage stems from vertically integrated operations—many suppliers operate end-to-end facilities capable of design, machining, assembly, and testing under one roof. This integration reduces component procurement delays and supports faster project turnaround. Buyers typically experience lead times of 30–60 days depending on complexity, with localized access to raw materials such as stainless steel, aluminum, and industrial polymers reducing overall system costs by 15–25% compared to equivalent Western-built systems.

How to Choose Own Production Line Suppliers?

Selecting a reliable supplier requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers possess in-house engineering teams and documented experience in designing turnkey production systems. For regulated industries (e.g., food, dairy, pharmaceuticals), ensure compliance with relevant standards such as ISO 9001, CE marking, or 3A sanitary certification. Request validation documentation for critical subsystems including conveyance, filling, sealing, sterilization, and control panels.

Production Infrastructure Assessment

Evaluate core operational capacity through verifiable metrics:

- Facility size exceeding 5,000m² indicates scalability for large-scale orders

- In-house CNC machining, welding, and automation integration capabilities enhance customization agility

- Dedicated R&D departments suggest ongoing innovation and adaptability to niche requirements

Cross-reference facility claims with on-time delivery performance (target ≥95%) and response efficiency (≤4 hours preferred).

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services until final inspection is completed. Prioritize suppliers with transparent transaction histories and verified export experience. Pre-shipment inspections and pilot run validations are strongly recommended, especially for high-value systems exceeding $100,000. Request video demonstrations of live machine operation before release of funds.

What Are the Best Own Production Line Suppliers?

| Company Name | Main Products | Price Range (Min. Order) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|

| He Nan Tiger Machinery Co., Ltd. | Food Process Production Lines, Packaging Machines, Heat Exchangers | $243,600/set | 100% | ≤1h | <15% | US $50,000+ |

| Zhengzhou Sunshine Machinery Equipment Co., Ltd. | Soap Making Machines, Chemical Equipment, Mixing Systems | $2,000–9,000/set | 100% | ≤1h | <15% | US $50,000+ |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Assembly Lines, Battery & EV Car Production Systems, Welding Lines | $23,000–95,430/set | 100% | ≤8h | - | - |

| Yingkou Professional Roll Forming Machine Co., Ltd. | Steel Drum/Barrel Production Lines, Metal Forming Systems | $30,000–280,000/set | 100% | ≤4h | - | US $10,000+ |

| Shanghai Qingji Beverage Machinery Co., Ltd. | Dairy & Soy Milk Processing Lines, UHT Sterilization Systems | $168,999–500,000/unit | 50% | ≤6h | 50% | US $280,000+ |

Performance Analysis

Suppliers like He Nan Tiger Machinery and Zhengzhou Sunshine offer cost-effective entry points into automated food and soap production, with consistent on-time delivery and rapid responsiveness. Zhengzhou Duoyuan stands out in high-tech sectors such as electric vehicle and battery assembly systems, combining advanced engineering with full-line integration. Yingkou Professional Roll Forming provides broad pricing flexibility for metal container manufacturing, catering to both mid-tier and premium budgets. Shanghai Qingji targets specialized beverage and dairy processors with high-capacity, fully automated lines, though its 50% on-time delivery rate warrants closer logistical scrutiny. Buyers should prioritize suppliers with documented export records and third-party quality audits when procuring mission-critical systems.

FAQs

How to verify own production line supplier reliability?

Cross-check ISO or CE certifications with issuing bodies. Request factory audit reports, equipment test videos, and client references. Analyze response consistency and technical depth in communication as indicators of operational maturity.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set. Lead times range from 30 days for standard soap or packaging lines to 60+ days for complex dairy, automotive, or chemical systems requiring custom engineering.

Can suppliers customize production lines?

Yes, most suppliers support OEM/ODM configurations. Provide detailed process flow diagrams, output targets (units/hour), power specifications, and space constraints for accurate design proposals. Custom control interfaces and language localization are commonly available.

Do suppliers provide installation and training?

Many offer remote guidance as standard; on-site commissioning and operator training may incur additional fees. Clarify service inclusions during negotiation, particularly for international deployments.

Are spare parts and after-sales support available?

Leading suppliers maintain inventory of critical components and provide technical troubleshooting via email or video call. Confirm availability of long-term support agreements and estimated part replacement lead times before purchase.