Format Factory Old

CN

CN

CN

CN

CN

CN

CN

CN

About format factory old

Where to Find Format Factory Old Equipment Suppliers?

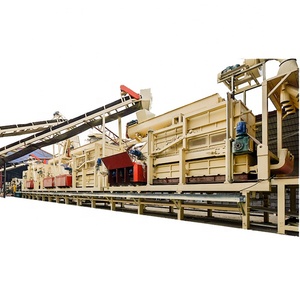

China remains the dominant hub for industrial machinery manufacturing, including legacy and refurbished production systems commonly referred to as "format factory old" equipment. Key supplier clusters are concentrated in Henan and Shandong provinces, where established industrial ecosystems support both new and reconditioned machinery production. Zhengzhou in Henan province hosts multiple manufacturers specializing in paper processing and food production lines, leveraging regional logistics networks for efficient export operations. Qingdao in Shandong province serves as a center for integrated recycling and packaging machinery systems, supported by proximity to port infrastructure and steel supply chains that reduce fabrication costs.

These regions offer vertically integrated manufacturing capabilities, enabling suppliers to provide end-to-end solutions—from component casting to full-line assembly. Buyers benefit from localized supply networks where raw materials, engineering talent, and testing facilities operate within close geographic proximity. This integration supports reduced lead times (typically 45–60 days for customized or refurbished systems), cost advantages of 20–30% compared to Western equivalents, and flexibility in scaling output or modifying system configurations.

How to Choose Format Factory Old Equipment Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm whether suppliers maintain in-house engineering teams capable of retrofitting or upgrading legacy systems. For paper recycling or food processing lines, verify compatibility with required input materials (e.g., waste paper types, nut varieties) and output specifications (e.g., paper width, paste consistency). Request detailed schematics and control system information—PLC-based automation (e.g., Delta PLC) is standard in modernized older lines.

Production and Refurbishment Infrastructure

Assess physical capacity and process maturity through the following indicators:

- Facility size exceeding 3,000m² to ensure space for assembly and testing

- In-house machining, welding, and electrical integration capabilities

- Presence of quality inspection protocols for reconditioned equipment

Cross-reference on-time delivery performance (target ≥95%) and response time (ideally ≤6 hours) to gauge operational reliability.

Transaction Security and Quality Assurance

Prioritize suppliers offering third-party inspection options prior to shipment. Review available documentation on material sourcing, safety compliance, and post-sale support. While formal certifications like ISO 9001 are not universally listed, consistent on-time delivery records and verifiable customer reorder activity indicate dependable service execution. Conduct video audits of factory floors to validate refurbishment processes and inventory status.

What Are the Leading Format Factory Old Equipment Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Customization Options | Revenue Transparency |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Dingchen Machinery Co., Ltd. | Henan, CN | Paper recycling & corrugated board lines | $90,000–$1,600,000 | 1 set | 100% | ≤7h | Yes | US $10,000+ |

| Qingdao YiDaFa International Trade Co., Ltd. | Shandong, CN | Waste paper recycling & pulp lines | $125,000–$220,000 | 1 set | 100% | ≤2h | Yes | Not specified |

| Zhengzhou Longer Machinery Co., Ltd. | Henan, CN | Peanut butter & RUTF processing lines | $12,899–$104,999 | 1 set | 100% | ≤2h | Limited | Not specified |

| Cangzhou Ipack Machinery Manufacture Co., Ltd. | Hebei, CN | Used/refurbished automatic lines | $17,000–$28,600 | 1 set | 100% | ≤6h | Yes | Not specified |

| Strong Machinery LLC | Hebei, CN | Snack food & carbonization lines | $4,500–$22,000 | 1 set | Not specified | ≤4h | Limited | Not specified |

Performance Analysis

Zhengzhou Dingchen Machinery offers high-value paper processing systems, including large-scale customized cylinder mold installations priced up to $1.6 million, indicating capability for complex turnkey projects. Qingdao YiDaFa demonstrates strong responsiveness (≤2h) and focuses on fully integrated waste-to-product paper lines. Zhengzhou Longer Machinery specializes in food-grade processing systems, particularly peanut-based products, with lower price points suitable for small to mid-sized operations. Cangzhou Ipack stands out for offering pre-owned, factory-refurbished automation lines at competitive prices, targeting budget-conscious buyers seeking functional legacy systems. Strong Machinery provides entry-level snack and thermal processing equipment, though limited transaction metrics suggest less proven export volume.

FAQs

What defines 'format factory old' equipment?

The term refers to previously operated or legacy industrial production lines that have been refurbished, upgraded, or repurposed for continued use. These systems often include paper recycling, food processing, or packaging machinery originally built for specific formats but adaptable to new inputs or outputs.

What is the typical minimum order quantity (MOQ)?

Most suppliers list MOQs at 1 set, reflecting the capital-intensive nature of industrial machinery. Pricing is typically quoted per complete line or unit, with no batch discounts unless multiple identical systems are ordered.

Are customization options available for older production lines?

Yes, many suppliers offer modifications to material feed systems, control panels, output dimensions, and labeling mechanisms. Customization depth varies—Zhengzhou Dingchen and Cangzhou Ipack explicitly list configurable parameters such as paper width, boiler type, and graphic design integration.

What lead times should be expected?

For refurbished or standard-configured lines, lead times range from 30 to 60 days. Fully customized or high-capacity systems (e.g., $1M+ paper lines) may require 90–120 days for re-engineering, testing, and preparation for shipment.

How can buyers verify equipment condition before purchase?

Request recent photos, videos of running machines, and maintenance logs. Third-party inspection services can conduct pre-shipment audits to assess mechanical integrity, safety compliance, and functionality. Video walkthroughs of the facility and live demonstrations are recommended for high-value procurements.